Numerical control (NC) drilling path optimization method and system and NC drilling equipment

A technology of processing path and optimization method, applied in the direction of digital control, electrical program control, etc., can solve the problems of not being able to obtain a global optimal solution, difficult to handle, slow convergence speed of simulated annealing algorithm, etc., to avoid falling into local extremum, The effect of reducing the amount of computation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

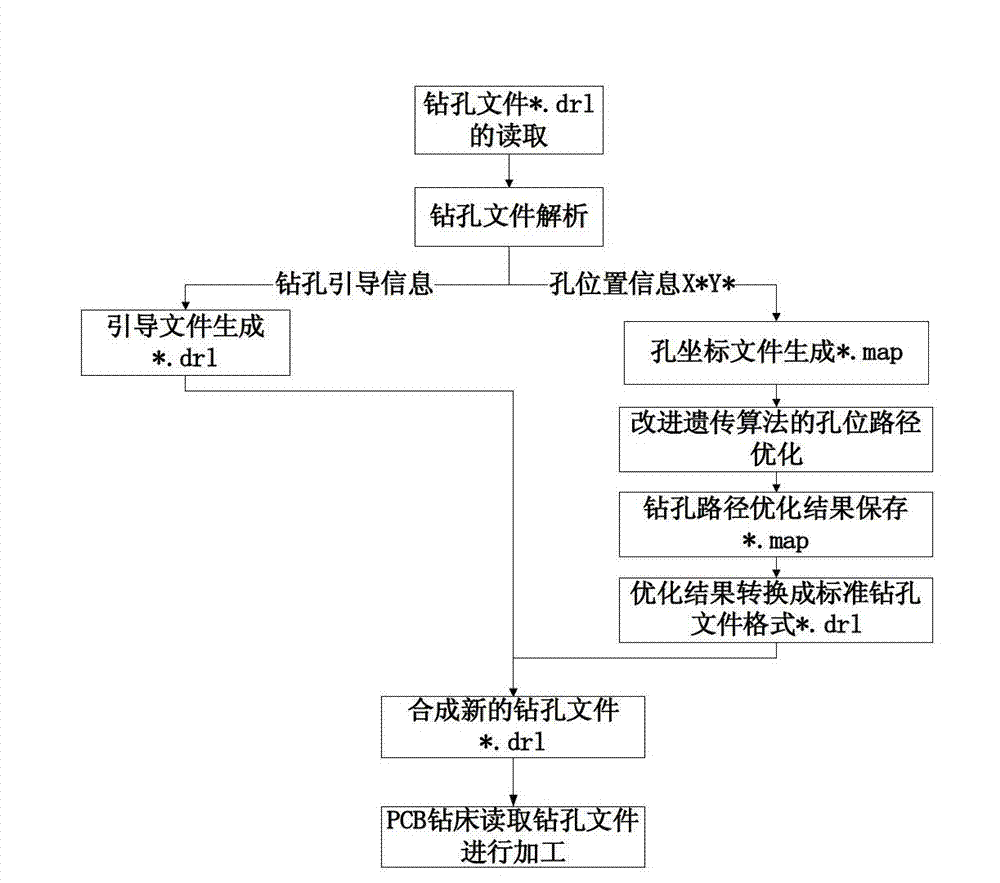

[0023] In the selection of optimization algorithm, considering that Genetic Algorithm (GA) is an adaptive global optimization probability search algorithm formed by simulating the genetic and evolution process of organisms in nature, it can quickly find the global optimal solution, can greatly reduce the amount of computation, so a design idea of this application is to use the genetic algorithm in the path optimization of the PCB CNC drilling process, but the genetic algorithm has the shortcomings of early convergence, inaccurate results, etc., to make up for the genetic algorithm is easy to fall into Due to the shortcomings of local extrema, this application makes improvements to the genetic algorithm used.

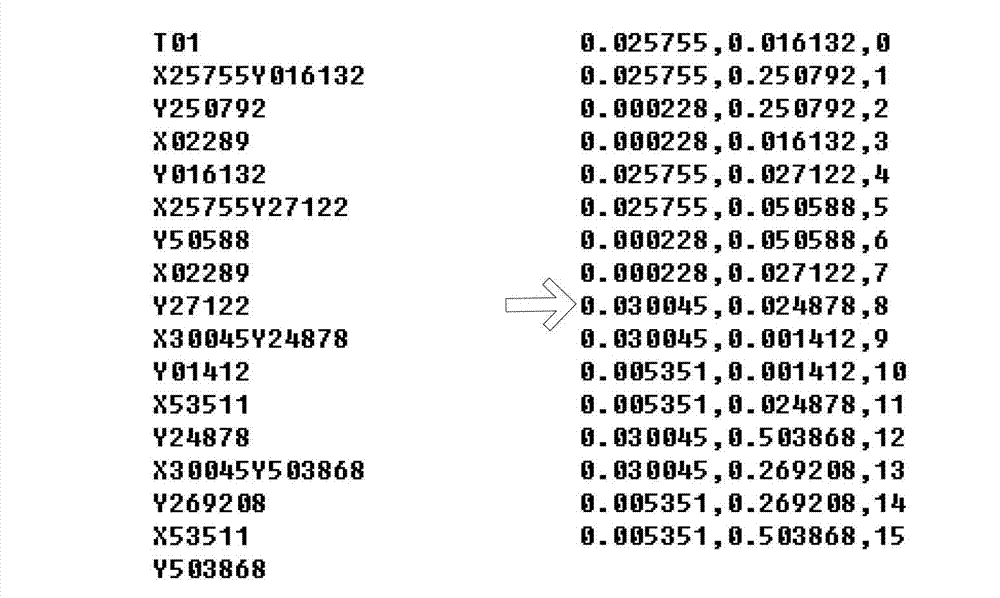

[0024] The present application will be further described in detail below through specific implementation methods in conjunction with the accompanying drawings, where a six-head PCB CNC drilling process is taken as an example, and of course other multi-axis PCB CNC drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com