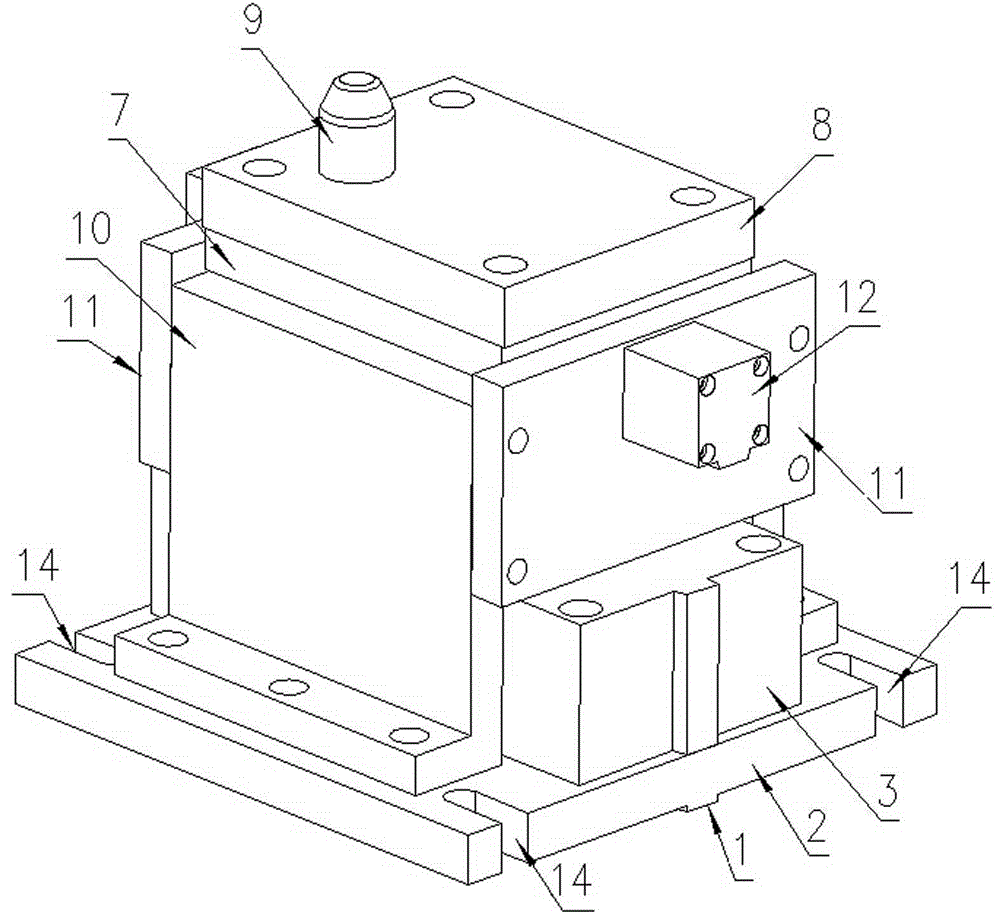

Fine-adjustment floating device for horizontal assembly of large electric motor

A technology of floating device and large motor, applied in electromechanical devices, electric components, manufacturing of motor generators, etc., can solve problems such as low assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

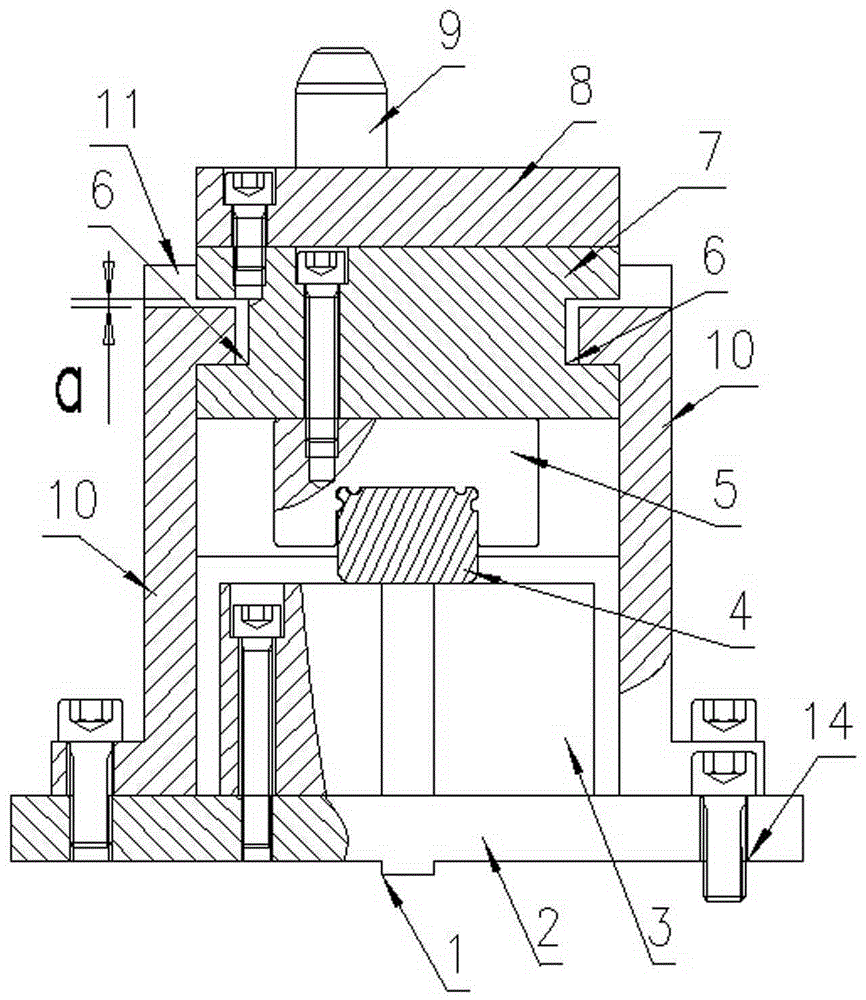

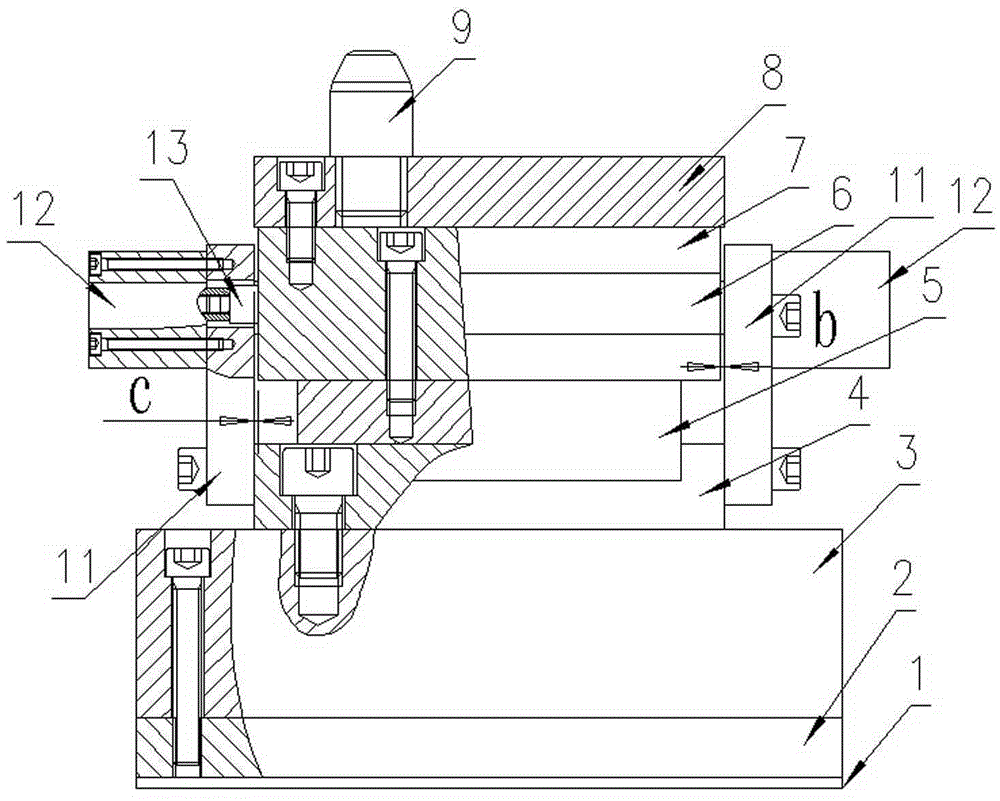

[0018] The fine-tuning floating device is assembled horizontally with a large motor, including the base 2 with the positioning key 1 protruding from the middle of the bottom surface along the front and rear directions, the upper and lower thin cylinders 3 fixed on the upper side of the base 2, and the linear guide rail 4 fixed on the upper and lower thin cylinders 3 along the front and rear directions , slidingly fitted on the sliding seat 5 on the linear guide rail 4, fixed on the sliding seat 5 and has a sliding bottom plate 7 with a long groove 6 opposite to the left and right, and an adjusting backing plate 8 fixed on the sliding bottom plate 7, vertically fixed on the adjusting backing plate 8 and the positioning taper pin 9 that is plugged and matched with the foot plate hole of the machine base, and two pressing plates 10 with a right-angled Z-shaped longitudinal section,

[0019] The two pressure plates 10 are respectively fixed on the base 2 on both sides of the up...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap