Braking apparatus for electric power tool

A technology of electric tools and braking devices, which is applied in the direction of deceleration devices, stop devices, and portable mobile devices of DC motors, which can solve problems such as large reaction force, damage to the user's sense of use, and poor electrical equipment, so as to prevent Effect of high temperature and prevention of regenerative current flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

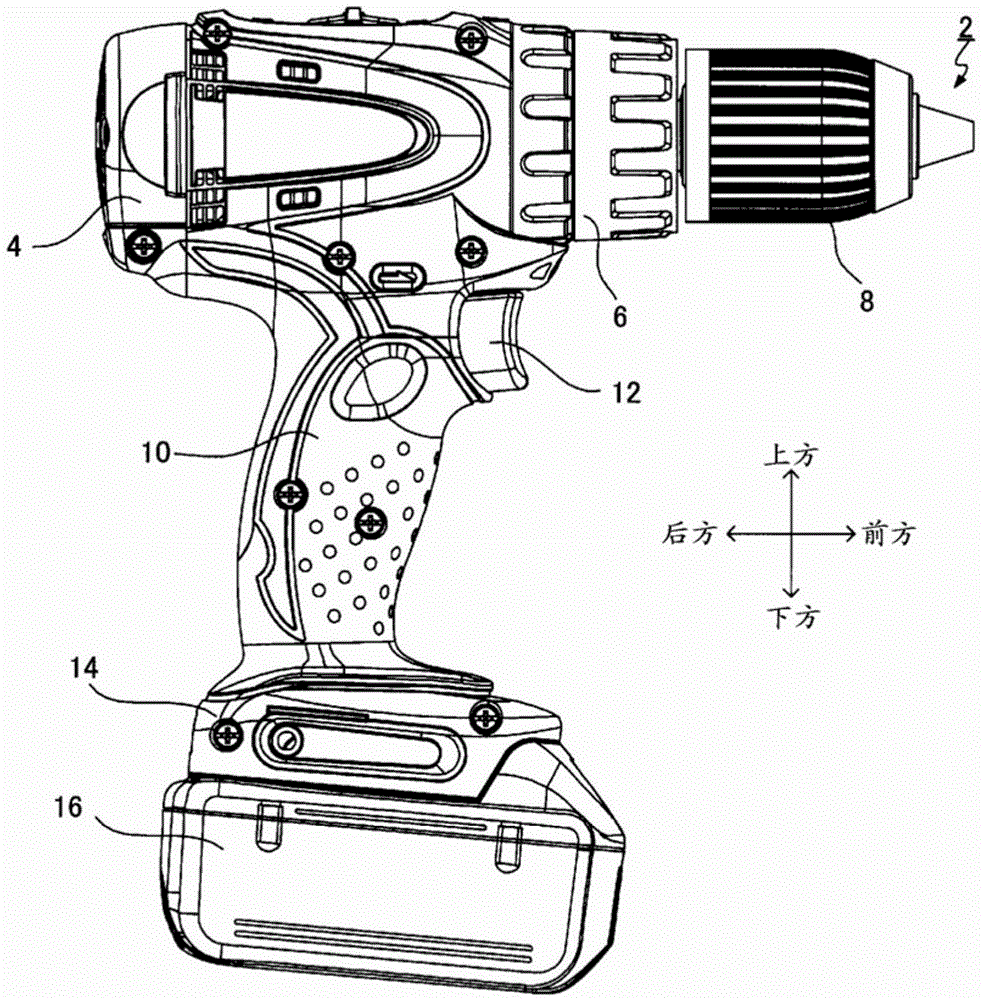

[0071] The following is attached Figure 1 Embodiments of the present invention will be described first.

[0072] like figure 1 As shown, the electric tool 2 of the present embodiment is a so-called electric drill, and includes a motor housing 4, a gear (Gear) housing 6 located in front of the motor housing 4, a drill chuck 8 located in front of the gear housing 6, and a drill chuck 8 located in front of the gear housing 6. The handle 10 below the motor housing 4.

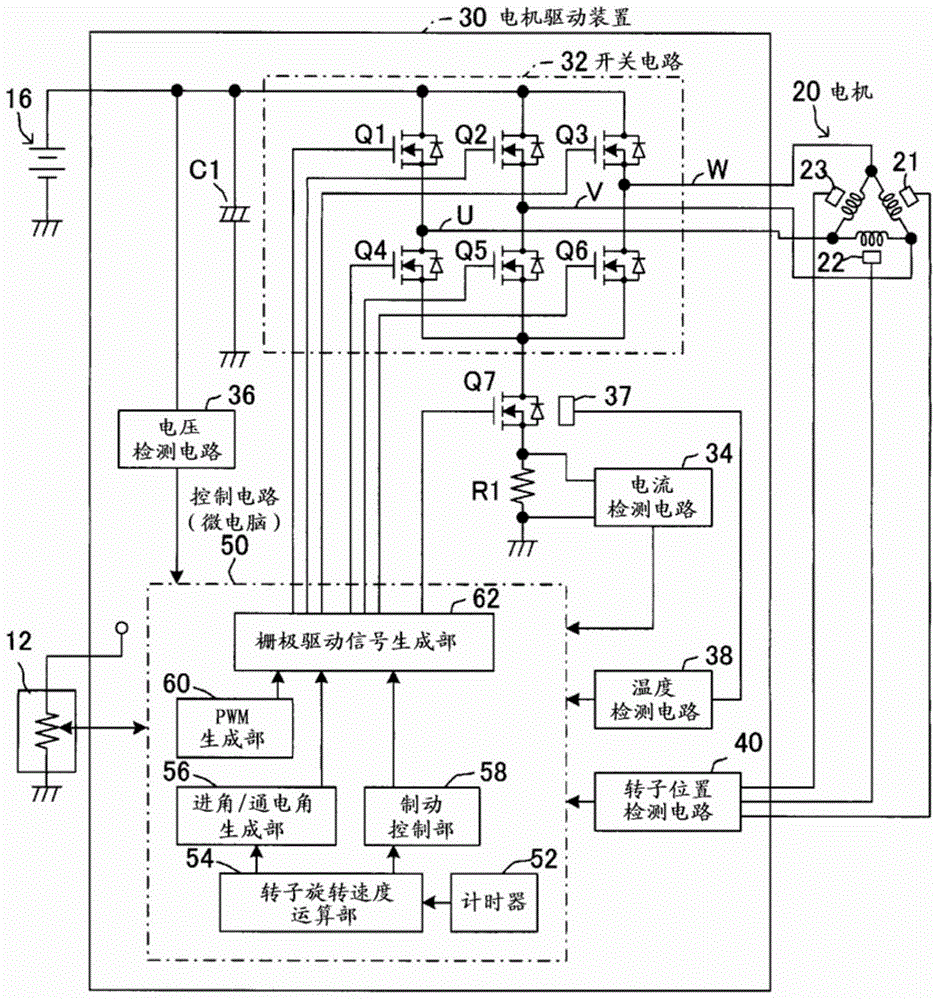

[0073] The motor housing 4 accommodates a motor 20 that generates a driving force that drives the drill chuck 8 (refer to figure 2 ). Furthermore, the motor 20 is a three-phase brushless motor. The gear case 6 accommodates a gear mechanism (not shown) that transmits the driving force of the motor 20 to the drill chuck 8 .

[0074] The drill chuck 8 includes an attachment mechanism (not shown) for detachably attaching a tool bit (not shown) to the front end portion of the drill chuck 8 .

[0075] The handle 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com