Mass of metal fibers and process for making such a mass

A technology of metal fibers and substances, applied in the direction of manufacturing tools, metal processing equipment, accessories of tool holders, etc., can solve problems such as inability to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

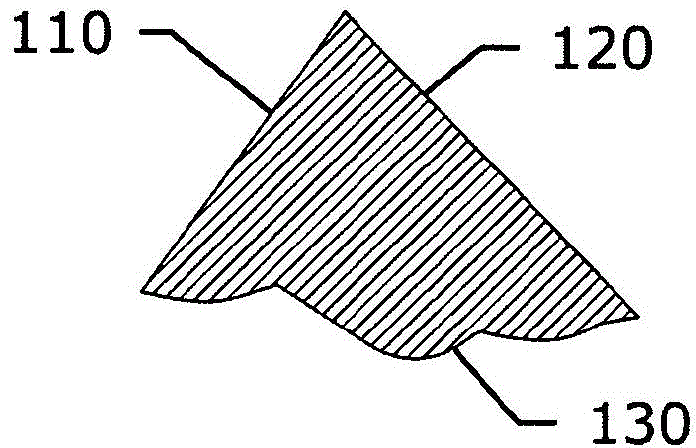

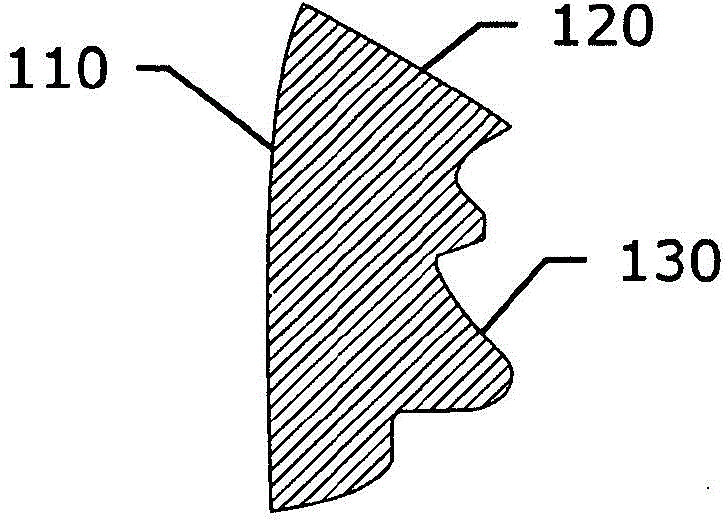

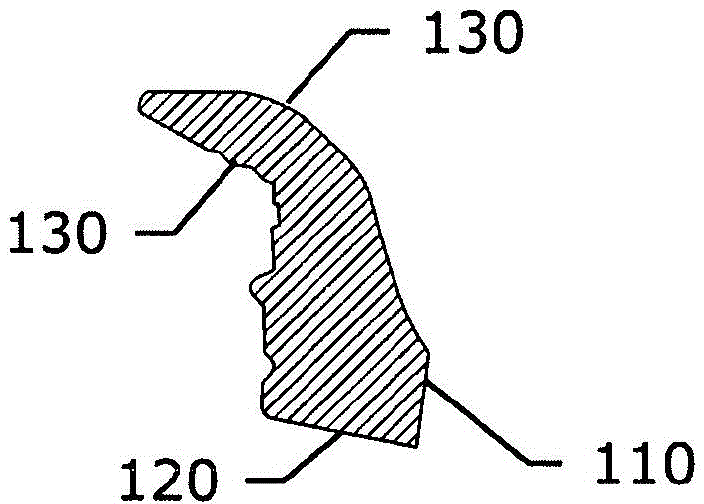

[0072] Figures 1 to 8 An example of the fiber section of the metal fiber obtained from the fibrous substance as the first aspect of the present invention is shown. The fiber section has two adjacent straight sides 110 , 120 with an included angle less than 90°, and the fiber section has one or more irregularly shaped curved sides 130 .

[0073] Figure 9 A cross-sectional view of an example apparatus for fiber cutting according to an embodiment of the third aspect of the invention is shown. A block 910 is provided. The block 910 will slide at a constant speed along the axis of the lathe (not shown in the figure). Sliding motion can be provided by pre-tensioned ball bearings.

[0074] The housing 915 is fixed on the block 910 . Housing 915 includes piezoelectric motor 920 . By measuring the rotational speed of the lathe, the vibration frequency of several kilohertz is synchronized electronically (with a suitable controller) to the rotational speed of the lathe. The tool ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com