Naked seed water sowing method for tobacco seedling culture

A bare seed and tobacco technology, which is applied in the field of bare seed water sowing of tobacco seedlings, can solve the problems of difficult control of the number of seeds in point sowing, high seed waste, and heavy workload of seedlings, so as to save the amount of seeds used and reduce the labor required for sowing , the effect of increasing the seeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

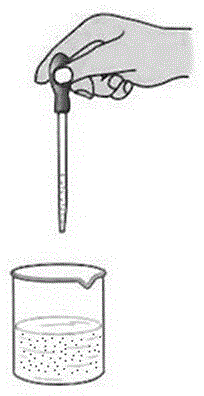

[0021] Take the Duchuan Tobacco Experimental Station in Fangxian County as an example for sowing seedlings in 288-hole seedling trays in the way of floating seedlings in greenhouses. On February 1st, the seedling tray, seedling substrate and tools for seedling cultivation were fumigated and disinfected. On February 20, the bottom of the seedling pond was disinfected with quicklime, and the ground was paved with plastic film to prevent water seepage or extravasation in the seedling pond. On February 25, inject an appropriate amount of water into the nursery pond, the water depth is 10 cm, add 1 Kg of tobacco-specific compound fertilizer (N:P2O5:K2O=10:12:20) per cubic water, and stir with a stick. The seeds were sown on February 27, and the seeds were the naked species of flue-cured tobacco variety Yunyan 87 harvested in August of the previous year.

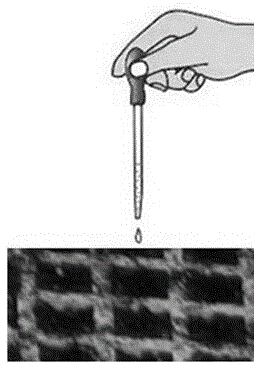

[0022] First, fill the seedling trays with the seedling substrate prepared in advance, and then place the seedling trays on the ...

Embodiment 2

[0027] Take the Duchuan Tobacco Experimental Station in Fangxian County as an example for sowing seedlings in 288-hole seedling trays in the way of floating seedlings in greenhouses. On February 1st, the seedling tray, seedling substrate and tools for seedling cultivation were fumigated and disinfected. On February 20, the bottom of the seedling pond was disinfected with quicklime, and the ground was paved with plastic film to prevent water seepage or extravasation in the seedling pond. On February 25, inject an appropriate amount of water into the nursery pond, the water depth is 10 cm, add 1 Kg of tobacco-specific compound fertilizer (N:P2O5:K2O=10:12:20) per cubic water, and stir with a stick. The seeds were sown on February 29, and the seeds were naked varieties of the flue-cured tobacco variety K326 harvested in August of the previous year.

[0028] First, fill the seedling trays with the seedling substrate prepared in advance, and then place the seedling trays on the sow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com