Efficient mixing tank for pta refining unit

A stirring tank, high-efficiency technology, applied in the direction of mixer accessories, mixers with rotating stirring devices, separation/purification of carboxylic acid compounds, etc., can solve the problem of raising the production cost of PTA, affecting the smooth production, and poor crystallization effect of the final product and other problems, to achieve the effect of improving the effect of eddy current mixing, not easy to age and deteriorate, and the service life is easy and fast to install.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

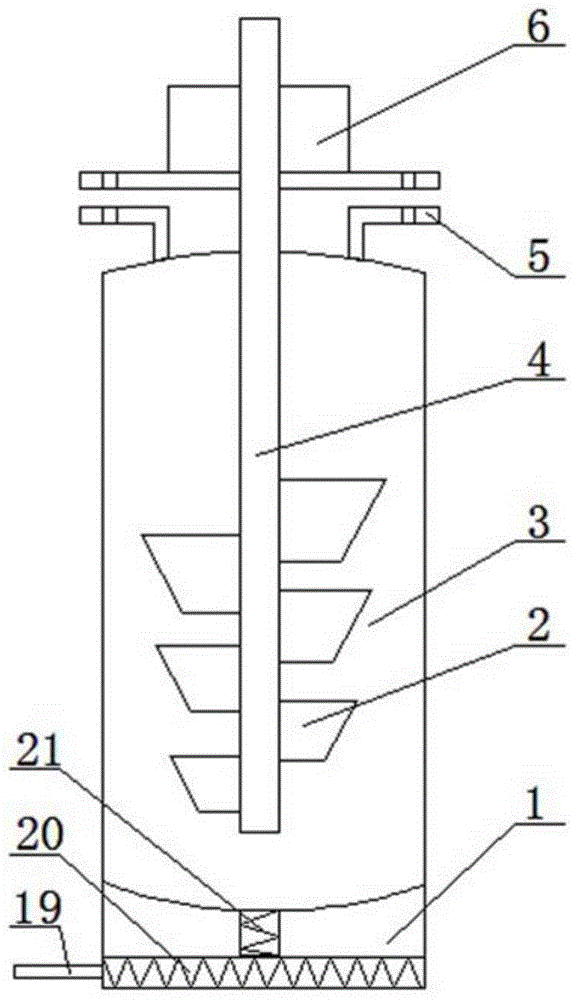

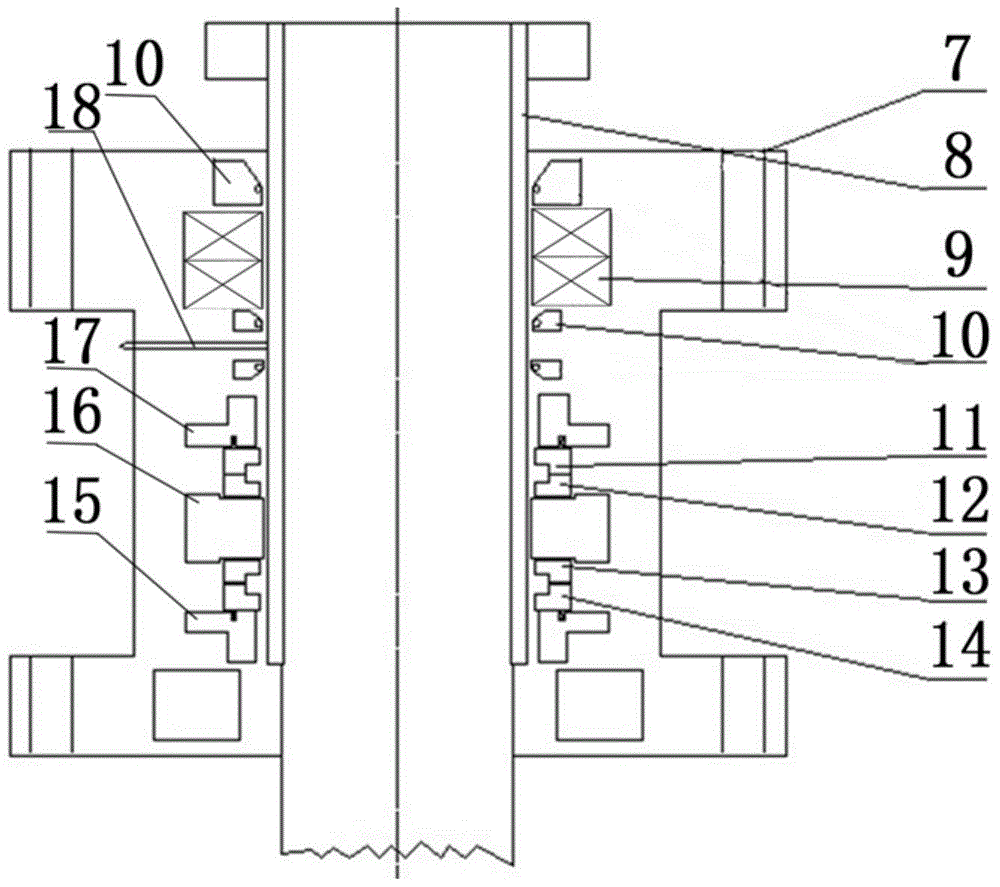

[0013] Example: According to Figure 1~2 The specific structure of the present invention will be described in detail. The high-efficiency stirring tank for the PTA refining unit includes a tank body 3, a skirt 1 arranged at the bottom of the tank body 3, an agitating shaft 4 arranged in the tank body 3, an agitating paddle 2 arranged at the end of the agitating shaft 4, an 3 The top mechanical seal device 6 and other parts. Wherein, the tank body includes a vertically distributed stirring layer, an intermediate spacer layer, and a liquid outlet layer. The bottom of the stirring layer is in an arc-shaped structure. A spiral pipe 20 is provided, and a liquid outlet 19 is provided at one end of the liquid outlet layer. The stirring paddle is in the shape of a right-angled trapezoid, and its right-angled side is parallel to the stirring shaft. There are three groups of stirring paddles, which increase in size from bottom to top. The mechanical seal device 6 includes an oil seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com