Method for enhancing screening consistency of lithium-ion power battery

A power battery, lithium ion technology, applied in the field of improving the consistency of screening lithium ion power batteries, can solve the problems of inability to characterize the polarization difference of the single battery and the performance of the battery pack, achieve high consistency, improve consistency, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

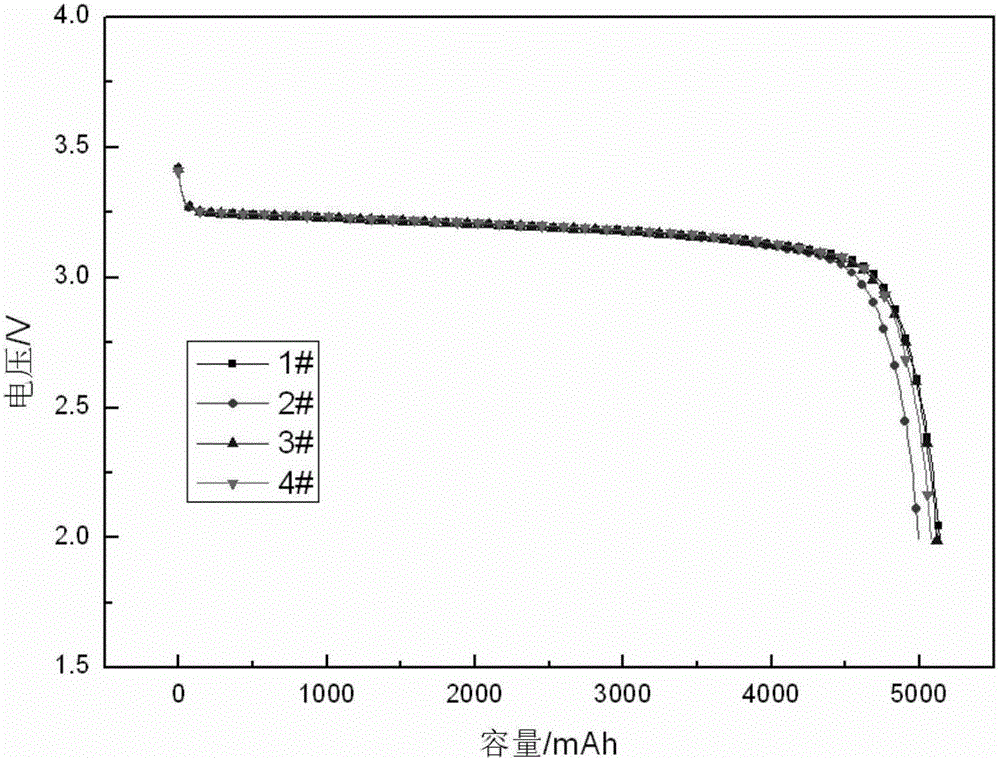

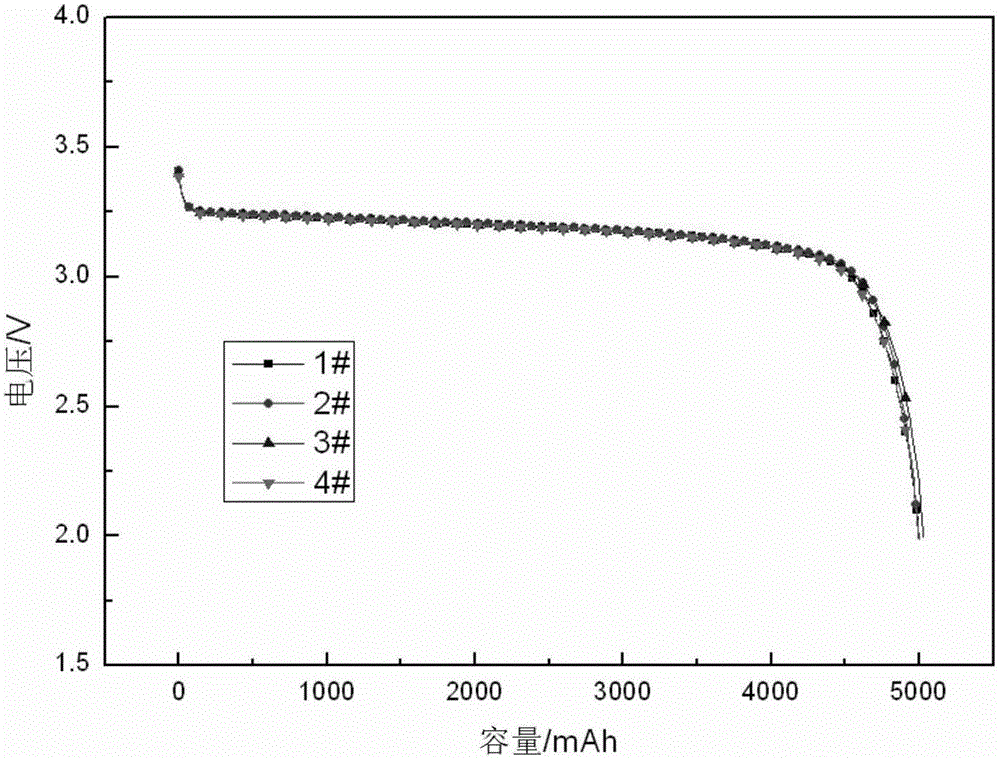

[0018] In order to highlight the superiority of the patent of the present invention, the conventional method for screening the consistency of lithium-ion power batteries and the method for screening the consistency of lithium-ion power batteries of the present invention are compared as follows:

[0019] 1) Conventional method

[0020] Take a battery with a nominal capacity of 5Ah. In order to ensure the accuracy of the experiment, the battery is fully charged and fully discharged 3 times before sorting, and the constant current ratio is above 90%. The platform time (different platform voltage is set according to different material systems) ) for 45min and the capacity difference is less than 50mAh.

[0021] Then put the sorted uncharged batteries at a high temperature of 45°C for 10 days, then at room temperature for 4-6 hours, and screen out 4 batteries with an internal resistance difference of 2-3mΩ and an uncharged open-circuit voltage difference within 100mV to assemble th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com