Electronic component lead pin bending device

A technology of a crimping device and electronic components, applied in the field of pin crimping devices, can solve problems such as difficulties, and achieve the effect of improving performance and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings and embodiments.

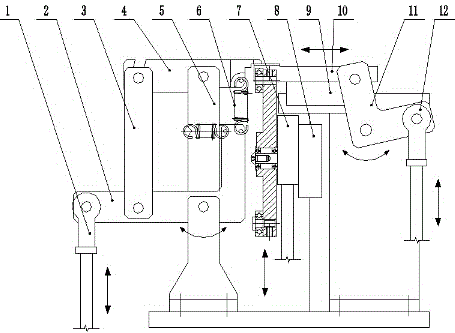

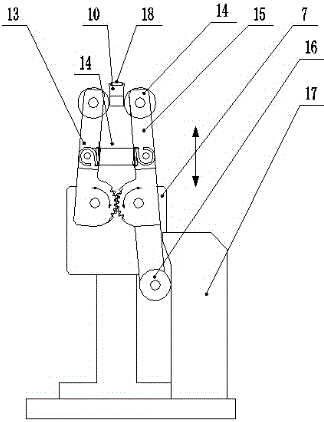

[0014] A pin bending device for electronic components, the first connecting rod 1 on the left is connected to one end of the horizontal side of an L-shaped force arm 2, and the L-shaped force arm 2 passes through an auxiliary arm perpendicular to its horizontal side 3 is connected with one end of a horizontal pressing arm 4, the middle part of the pressing arm 4 is connected with a rocker arm 5, and the other end of the pressing arm 4 is connected to the vertical side of the L-shaped force arm 2 through a spring 6 Connection; the second connecting rod 12 on the right side is connected to one end of a translation arm 11, and the other end of the translation arm 11 can slide on the linear guide rail 9, and a molding die 10 is connected to the linear guide rail 9 , the forming die 10 and the one end of the spring 6 connected to the pressing arm 4 are close to each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com