Motion platform system of 3D (three-dimensional) ceramic printer

A motion platform and printer technology, applied in the field of 3D printing, can solve the problems of high investment cost, many accessories, and inconvenient use, and achieve the effects of low investment cost, simple structure, and improved printing accuracy and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

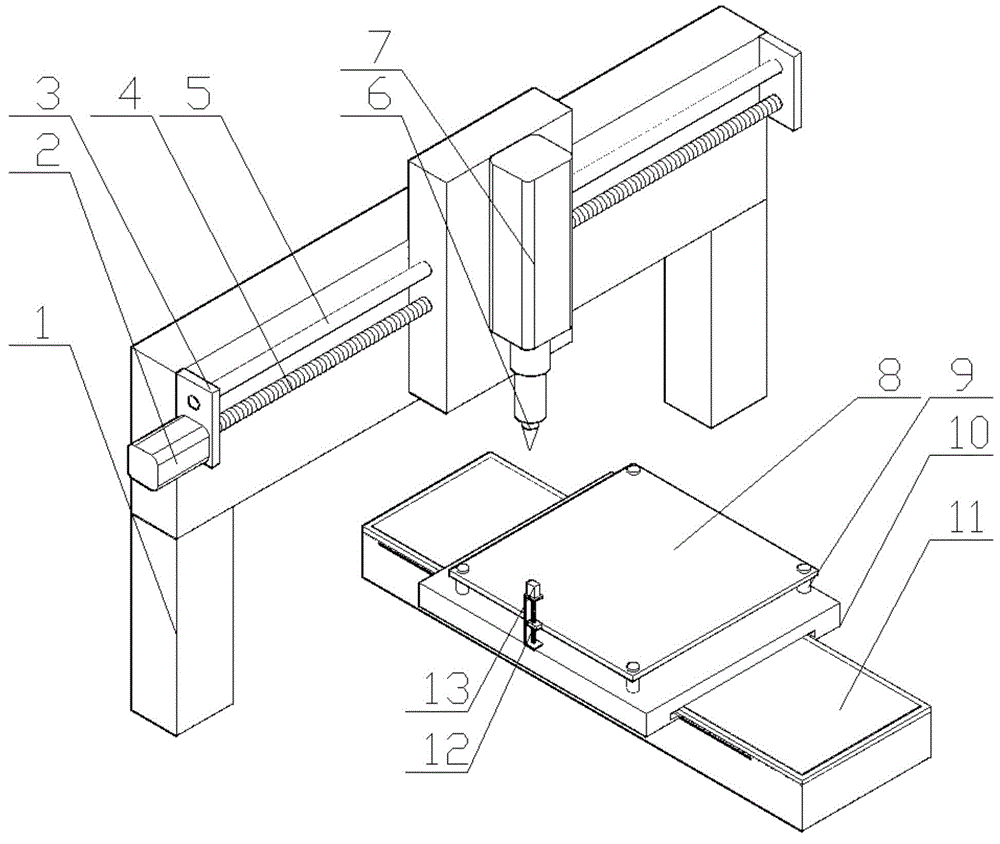

[0018] like figure 1 As shown, the present invention includes a base 11, a frame 1 composed of two vertical supports and a horizontal support, a Y-axis motor installed inside the base 11, a slidably mounted base 11 and driven by the Y-axis motor The mobile workbench 10 that moves back and forth along the horizontal Y-axis direction, the four vertical polished rods 9 fixedly welded to the four corners of the mobile workbench 10 respectively, and the pavement that is slidably installed on the four vertical polished rods 9 Material platform 8, set on the vertical screw rod and fixedly connected with one end of the material spreading platform 8 The mobile nut block 12 is used to drive the mobile nut block 12 to move up and down along the vertical screw rod so as to drive the material spreading platform 8 along the The vertical light rod 9 moves up and down the material spreading platform lifting motor 13, the two baffle plates 3 installed on the left and right sides of the horizon...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap