Flexible upper prestressing adjusting device

A technology of adjusting device and pre-pressing, which is applied to presses, material-forming presses, manufacturing tools, etc., can solve problems such as failure to achieve pre-pressing effect, difficult adjustment of pre-pressing position, and increase of material-pressing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] The present invention will be further described below in conjunction with accompanying drawings and embodiments.

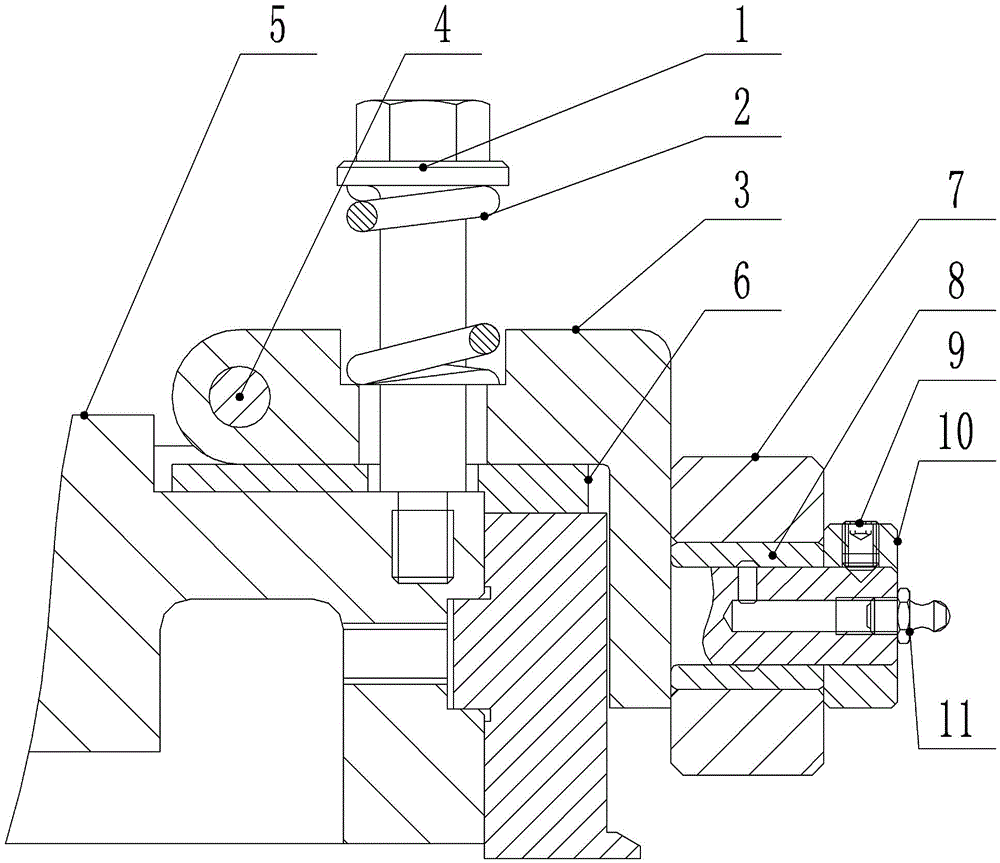

[0007] like figure 1 As shown, the flexible upper preload adjustment device of the present invention includes a shaft position screw 1, a spring 2, a preload wheel frame 3, a cap nail 4, an upper track disc 5, a gasket 6, a preload wheel 7, a preload wheel cover 8, Locking screw 9, retaining ring 10, pressure oil cup 11, wherein the pre-loading wheel frame 3 is connected with the upper track plate 5 through the cap nail 4, the gasket 6 is installed between the pre-loading wheel frame 3 and the upper track plate 5, and the spring 2 is set On the shaft position screw 1, the shaft position screw 1 penetrates the pre-compression wheel frame 3 and fixes it on the upper track disc 5, and the pre-compression wheel sleeve 8 is put into the inner hole of the pre-compression wheel 7 and then set on the pre-compression wheel frame 3. The retaining ring 10 is set on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com