Lifting and transverse moving clamp of water heater clamp transfer machine

A technology of lifting, moving, and transferring machines. It is applied in the direction of conveyor objects, transportation, and packaging. It can solve the problems of heavy water heaters, workers unable to bear the workload, and reduced work efficiency. It achieves convenient maintenance and simple and practical design structure. , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

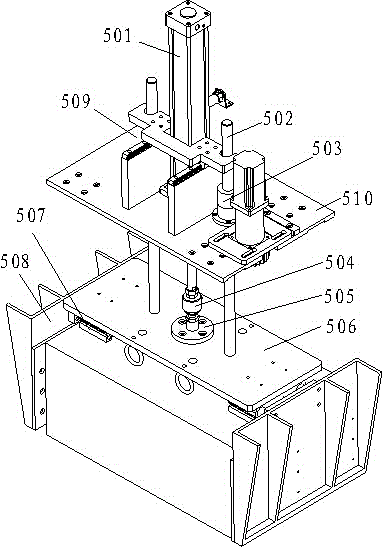

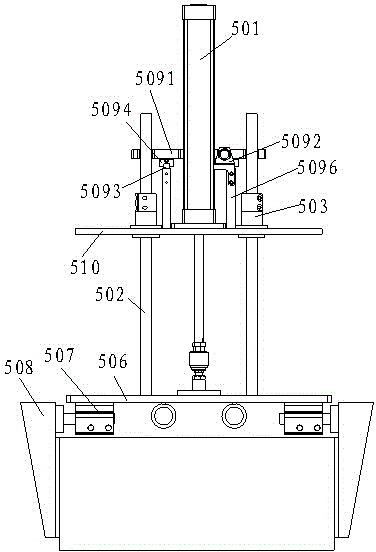

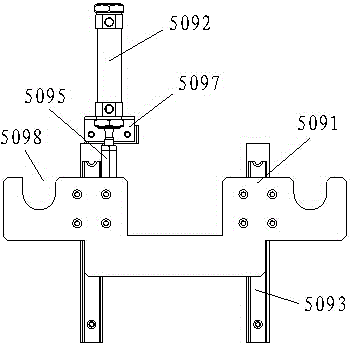

[0011] see Figure 1 to Figure 3 , the embodiment of the present invention includes:

[0012] A lifting and traversing clip of a water heater bag transfer machine, which includes a lifting cylinder 501, a lifting guide post 502, a lifting guide sleeve 503, a floating connector 504, and a flange connector 505, lifting plate 506, anti-slip clamping plate 507, double piston rod clamping cylinder 508 and pneumatic slow down device 509, the lifting cylinder 501 is installed on the traversing base plate 510, and the piston rod of the lifting cylinder 501 passes through the traversing base plate 510 , the piston rod of the lifting cylinder 501 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com