Reaction method and device for strengthening Cr (VI) reduction based on square wave power supply

A reaction device and power supply technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of reducing Cr reduction efficiency, low mass transfer efficiency, etc., achieve stable reduction, reduce passivation reaction, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

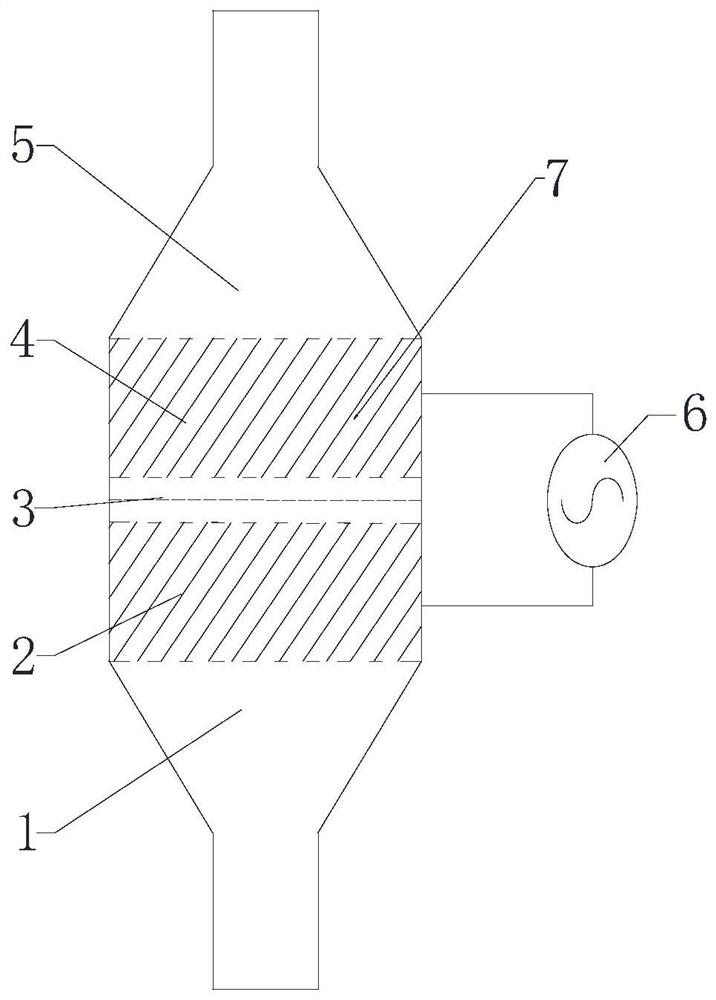

[0039] Such as figure 1 Shown, a kind of reaction device based on square-wave power supply strengthening Cr(VI) reduction comprises reactor, insulating layer 3, porous electrode 7 and square-wave power supply 6, and the two ends of reactor are all provided with conical port, The two ports are respectively a water inlet 1 and a water outlet 5. The insulating layer 3 divides the reaction chamber into a first reaction chamber 2 and a second reaction chamber 4. A porous electrode 7 is installed in the first reaction chamber 2, and the other The porous electrodes 7 are installed in the second reaction chamber 4, and the two porous electrodes 7 are connected to the square wave power supply 6 through Ti wires or Pt wires. Materials for making porous electrodes include carbon-based or metal-based porous conductive materials, such as graphene sponge, carbon nanotube sponge, carbon fiber felt, glassy carbon, Ti foam, Ag foam, Au foam and other materials.

[0040] A kind of reaction met...

Embodiment 2

[0049] Except for the following technical features in this embodiment, other technical features are the same as those in Embodiment 1:

[0050] Both the porous electrode 7 of the first reaction chamber 2 and the porous electrode 7 of the second reaction chamber 4 in this embodiment are made of a 5 mm thick graphene sponge instead of a 10 mm thick carbon fiber felt.

[0051] In this embodiment, the diameters of the porous electrode 7 of the first reaction chamber 2 and the porous electrode 7 of the second reaction chamber 4 are both 5 cm instead of 10 cm.

[0052] The flux of the reaction device in the present embodiment adopts 1500L / h / m 2 Instead of 500L / h / m 2 .

[0053] The Cr(VI) solution in this embodiment uses 20 mg / L Cr(VI) solution (pH 6) instead of 20 mg / L Cr(VI) solution (pH 2).

[0054] The square wave power supply 6 in this embodiment uses AC current instead of AC voltage, and uses high-level current 10mA and low-level current -10mA instead of high-level voltage 1...

Embodiment 3

[0058] Except for the following technical features in this embodiment, other technical features are the same as those in Embodiment 1:

[0059] In this embodiment, the porous electrode 7 of the first reaction chamber 2 and the porous electrode 7 of the second reaction chamber 4 are both made of Ti foam with a thickness of 2.5 mm instead of carbon fiber felt with a thickness of 10 mm.

[0060] In this embodiment, the diameters of the porous electrode 7 of the first reaction chamber 2 and the porous electrode 7 of the second reaction chamber 4 are both 5 cm instead of 10 cm.

[0061] The throughput of the reaction device in this embodiment adopts 1000L / h / m 2 Instead of 500L / h / m 2 .

[0062] The Cr(VI) solution in this example is 5 mg / L Cr(VI) solution (pH 8) instead of 20 mg / L Cr(VI) solution (pH 2).

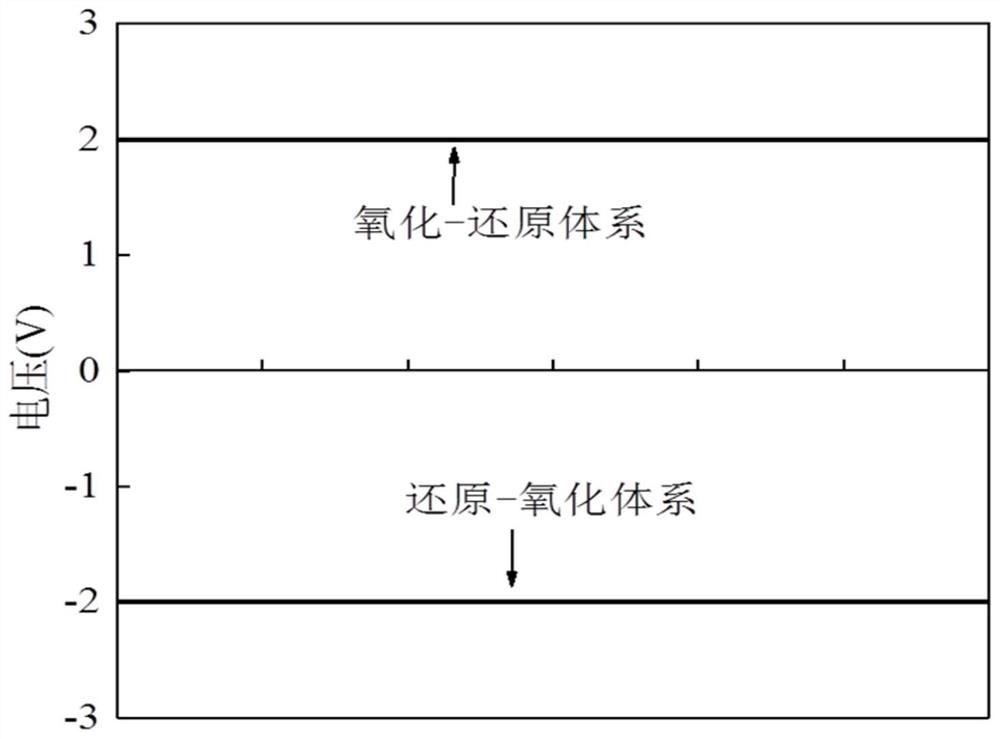

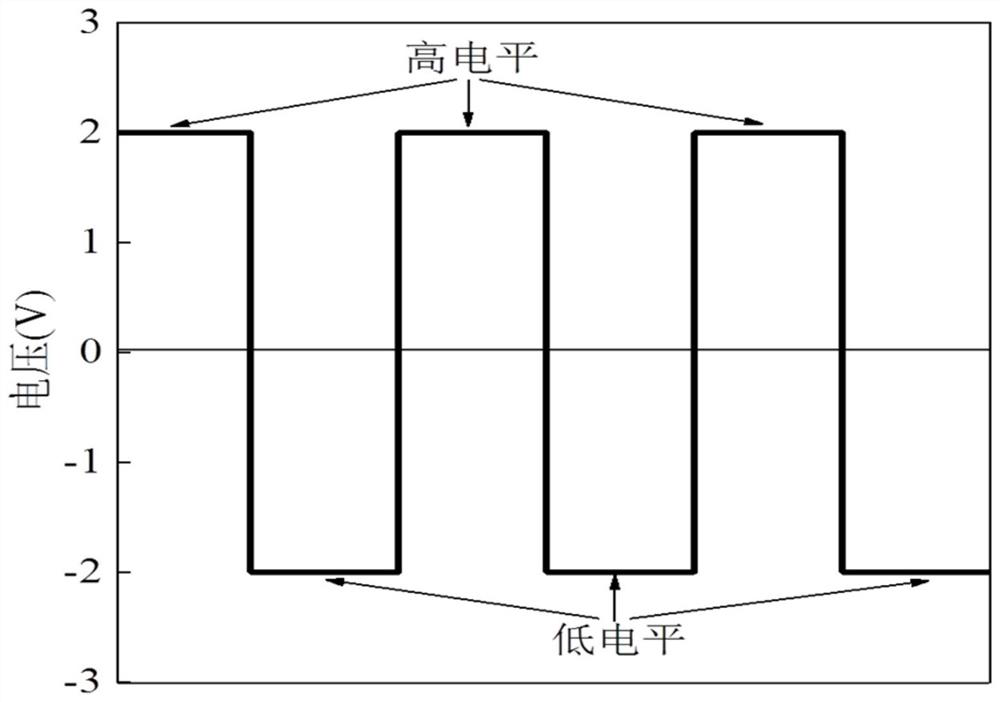

[0063] Such as Figure 5 Shown, a kind of reaction device (this embodiment) that strengthens Cr (VI) reduction based on square wave power supply: the power supply mode of squa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com