Automatic fetching device

An automatic retrieving and No. 1 technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of workpiece falling damage, scratching the workpiece, weak suction force, etc., to reduce the damage of the workpiece, ensure normal use, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

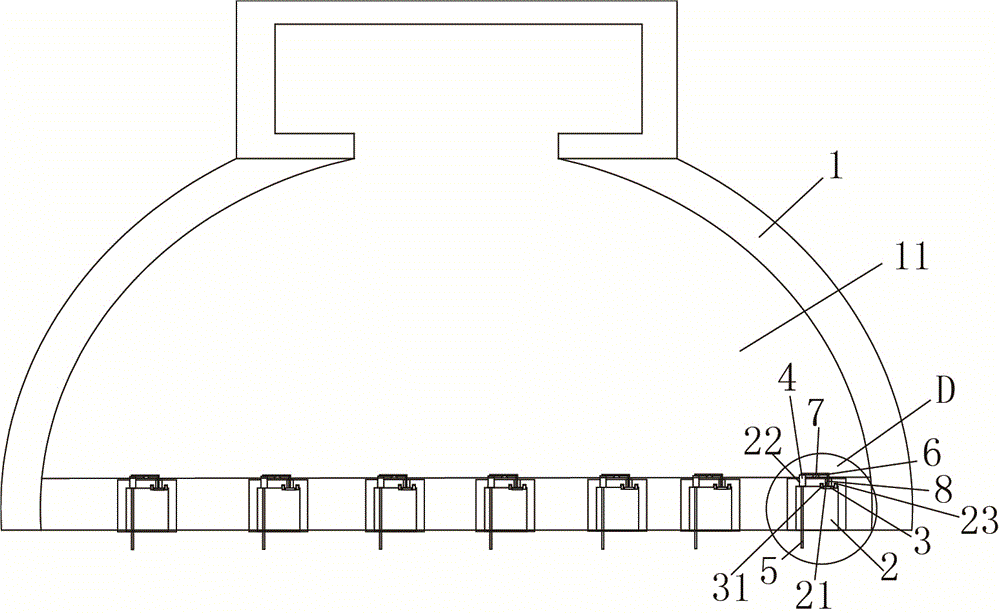

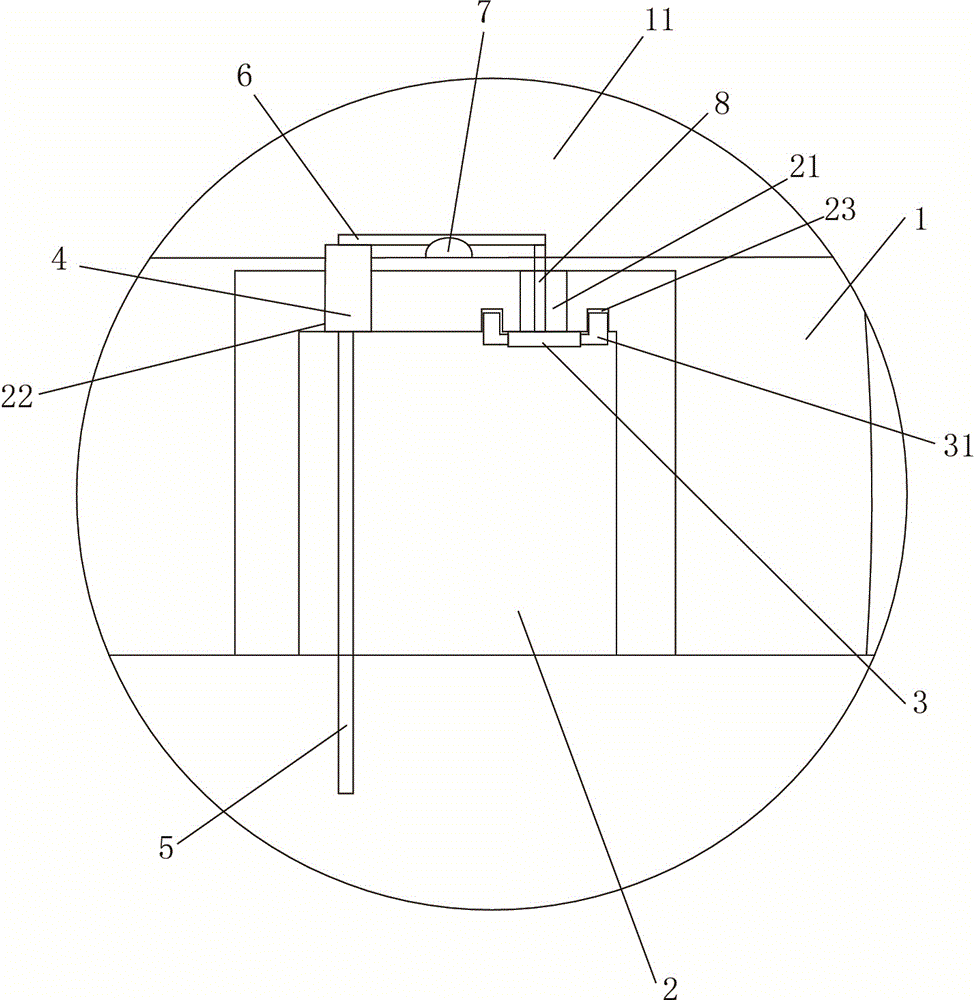

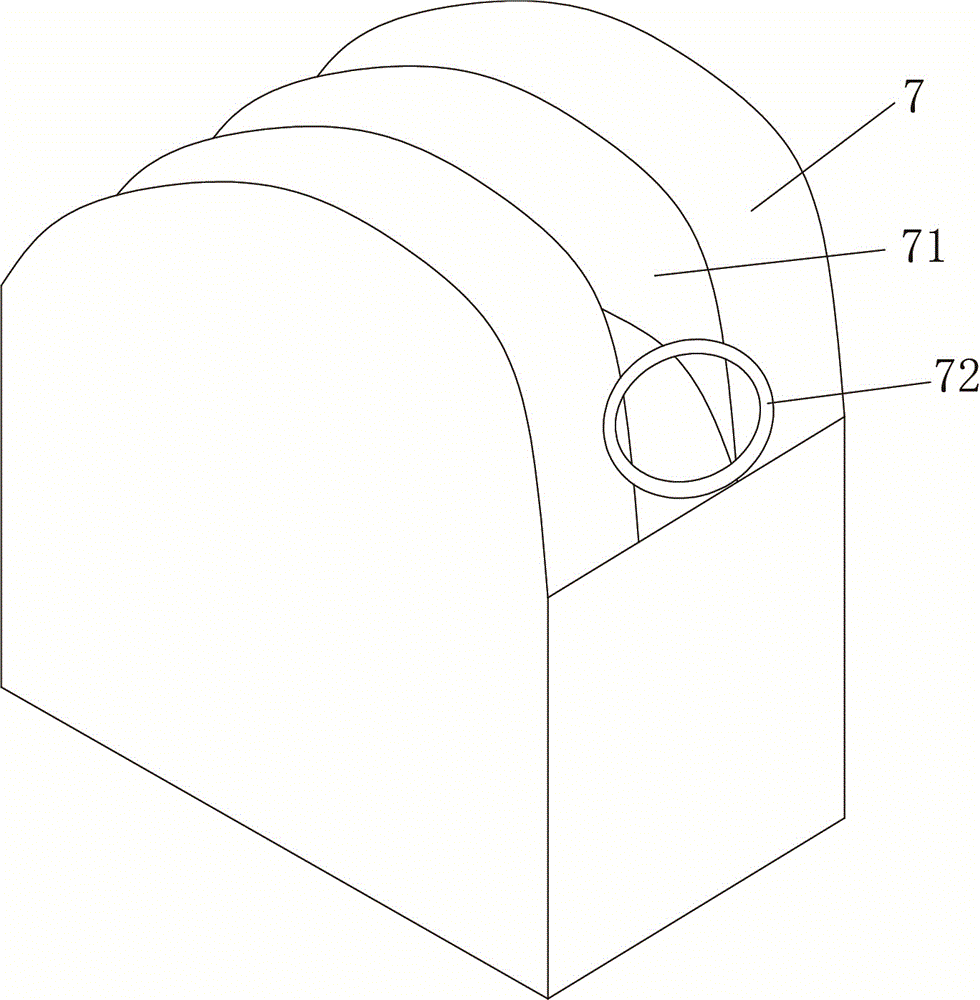

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1-Figure 3 , an automatic material retrieving device, including a housing 1, a cavity 11 is opened in the housing 1, the cavity 11 communicates with the air pump, and a number of ones are provided on the outer surface of the housing 1 Groove 2, the bottom surface of the No. 1 groove 2 is provided with a No. 1 through hole 21 and a No. 2 through hole 22 communicating with the cavity 11, and a movable sealing No. 1 through hole 21 is provided at the No. 1 through hole 21. The sealing sheet 3 of the hole 21, the No. 2 through hole 22 is provided with a rubber membrane 4 that seals the No. 2 through hole 22, and the side of the rubber membrane 4 facing the No. 1 groove 2 is fixedly connected with a support rod 5. The other side is hinged with a No. 1 connecting rod 6, and the No. 1 connecting rod 6 is supported by a support block 7. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com