Ecological organic phosphorus fertilizer and preparation method of ecological organic phosphorus fertilizer

An organic phosphorus and ecological technology, applied in the direction of organic fertilizers, fertilizers made of biological waste, nitrogen fertilizers, etc., can solve the problems of not being able to play a good role, the utilization rate of filter mud is not high, and the effect of fertilizers is limited, so as to achieve good results. Market potential, improvement of soil permeability, effect of soil improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

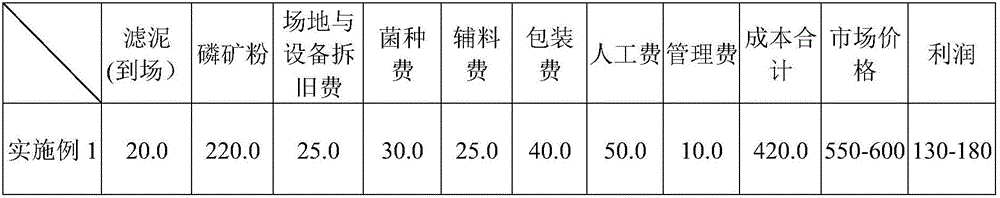

Embodiment 1

[0023] (1) prepare materials by the component of following quality: water content 70% (mass percentage) sucrose fresh filter mud 10000kg, P 2 o 5 4000kg of phosphate rock powder with a mass percentage content of 30%, 100kg of rice bran, 50kg of urea, and 20kg of bacterial agent Wobao biological straw decomposing agent;

[0024] (2) Carry out the following operations with the materials prepared in step (1): mix the bacterial agent with rice bran and urea evenly to obtain the masterbatch for subsequent use;

[0025] (3) fully stir and mix the filter mud, phosphate rock powder and masterbatch of step (1) to obtain a mixture, then pile the mixture into a rectangular trapezoidal pile with a width of 110 cm and a height of 95 cm; the fermentation temperature is maintained for 5 to 7 Days later, turn the pile again, turn the pile once every 7 days, and continue for 3 to 5 times. When the temperature drops to normal temperature, the material is loose, there is no original odor of the...

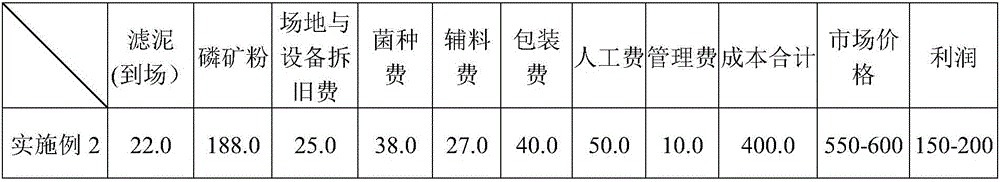

Embodiment 2

[0032] (1) Prepare materials according to the following components: water content 65% (mass percentage) sucrose fresh filter mud 10154kg, 35% phosphate rock powder 3400kg, rice bran 110kg, urea 60kg, bacterial agent Wobao biological straw decomposing agent 25kg;

[0033] (2) Carry out the following operations with the materials prepared in step (1): mix the bacterial agent with rice bran and urea evenly to obtain the masterbatch for subsequent use;

[0034] (3) fully stir and mix the filter mud, phosphate rock powder and masterbatch in step (1) to obtain a mixture, then pile the mixture into a rectangular trapezoidal stack with a width of 100 cm and a height of 90 cm; Days later, turn the pile again, turn the pile once every 7 days, and continue for 3 to 5 times. When the temperature drops to normal temperature, the material is loose, there is no original odor of the material, and there is a slight ammonia smell. White hyphae are produced in the pile, and the obtained Decompos...

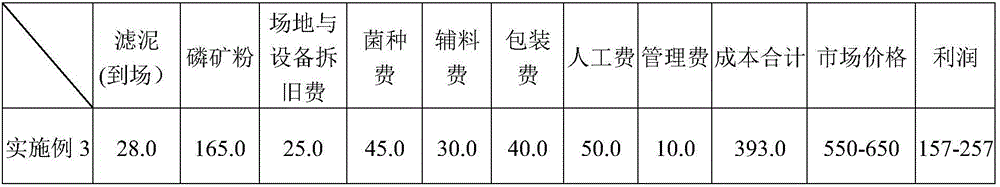

Embodiment 3

[0041] (1) Prepare materials according to the following components: 14000kg of sucrose fresh filter mud (water content 65%), 3000kg of 40% phosphate rock powder, 125kg of rice bran, 75kg of urea, 30kg of bacterial agent Wobao biological straw decomposing agent;

[0042] (2) Carry out the following operations with the materials prepared in step (1): mix the bacterial agent with rice bran and urea evenly to obtain the masterbatch for subsequent use;

[0043](3) fully stir and mix the filter mud, phosphate rock powder and masterbatch of step (1) to obtain a mixture, then pile the mixture into a rectangular trapezoidal pile with a width of 105 cm and a height of 100 cm; the fermentation temperature is maintained for 5 to 7 Days later, turn the pile again, turn the pile once every 7 days, and continue for 3 to 5 times. When the temperature drops to normal temperature, the material is loose, there is no original odor of the material, and there is a slight ammonia smell. White hyphae ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com