Low-rise assembled steel-structured residential container system

A prefabricated, steel structure technology, applied in the direction of residential construction, etc., can solve the problems of high cost constraints of steel structure housing, and achieve the effects of improving efficiency, reducing costs, and improving the level of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

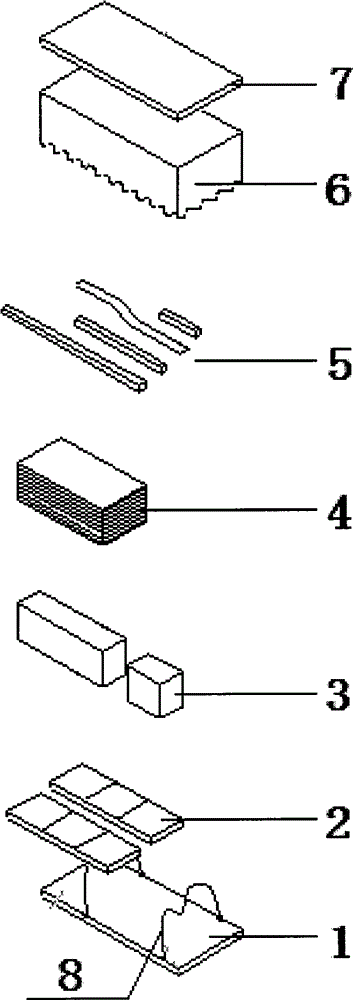

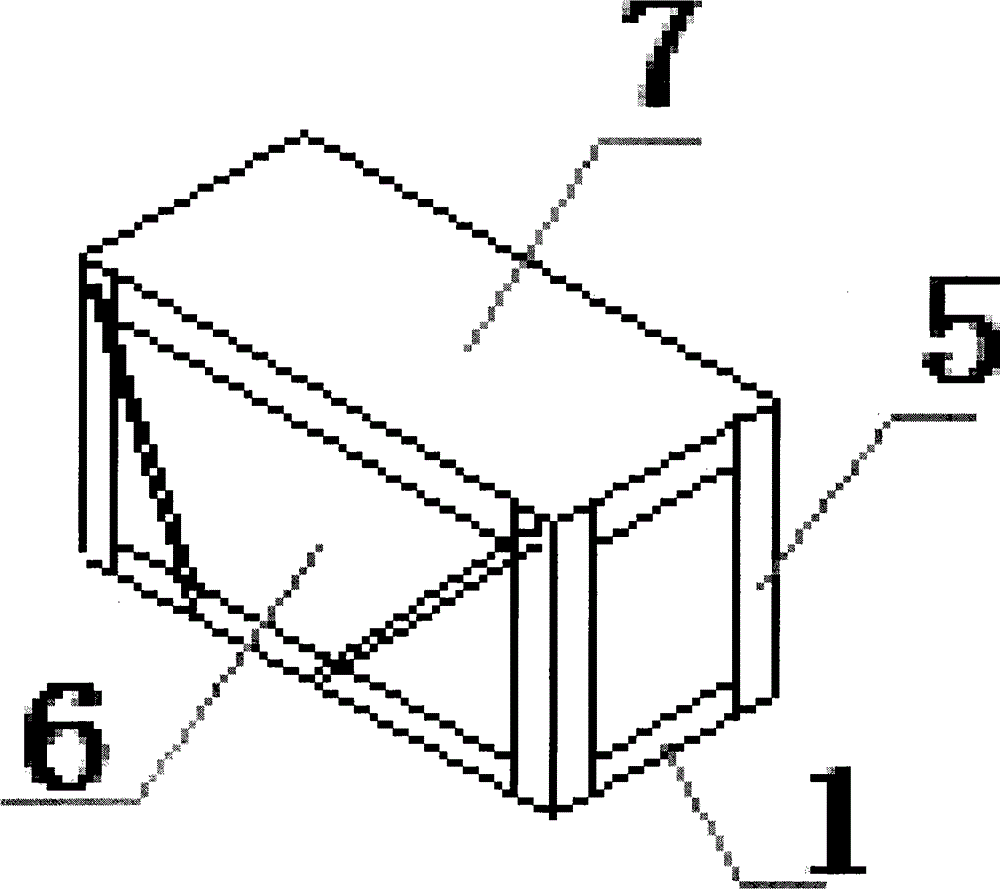

[0010] like figure 1 , 2 As shown, the low-rise prefabricated steel structure residential container system of the present invention includes a lower chassis 1, doors and windows 2 placed around the top of the lower chassis 1, and packing materials 3 placed on the lower chassis 1, and supporting members are placed on the edges of the doors and windows 2 5. Binding ropes 8 fixed on the lower chassis 1, said binding ropes 8 are used to bind together the goods 4 placed in the container, packing materials 3, doors and windows 2 and support members 5; above and around the doors and windows 2 A PVC cover 6 is covered, and an upper chassis 7 is arranged above the PVC cover 6 .

[0011] The assembly process of the low-rise assembled steel structure residential container system of the present invention is as follows:

[0012] 1) Split the low-rise prefabricated steel structure house into modules, and classify and integrate all the items inside each module.

[0013] 2) Stack doors and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com