Worm

A worm, journal technology, applied to the worm. It can solve the problems of unstable transmission, wear of worm, inability to meet processing requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

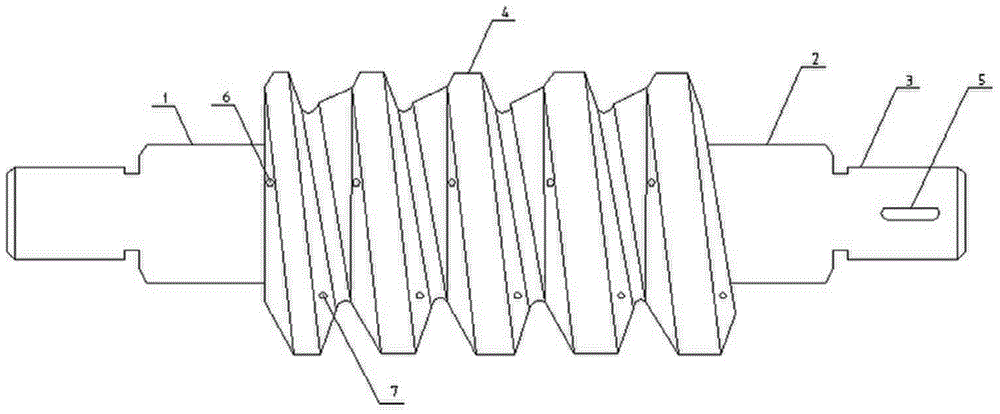

[0011] As shown in the figure: the present invention provides a worm, including a left journal 1, a right journal 2 and a shaft head 3, a helical tooth 4 is provided between the left journal 1 and the right journal 2, and the helical tooth 4 is used for The meshing of the worm gear, the oil passage of the lubricating oil inside the transmission friction surface of the helical tooth 2, when the worm moves, the oil inlet 6 of the lubricating oil passage on the non-friction surface of the worm is filled with lubricating oil, passes through the oil passage, and is on the friction surface of the worm. The outlet 7 of the lubricating oil channel allows oil to be injected into the friction surface between the turbine and the worm, so that the friction between the turbine and the worm is reduced and the wear is reduced. The pitch of the worm increases from left to right. During use , when the worm is worn, thin the adjusting gasket, move the worm axis to the left for a certain distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com