Hydraulic flat valve

A flat valve, hydraulic technology, applied in sliding valve, valve details, valve device and other directions, can solve the problems of high economic cost, unsatisfactory effect, valve can not withstand severe cold weather, buffer liquid pressure and external pressure, etc., to ensure smooth operation. The effect of preventing the force area from being too small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

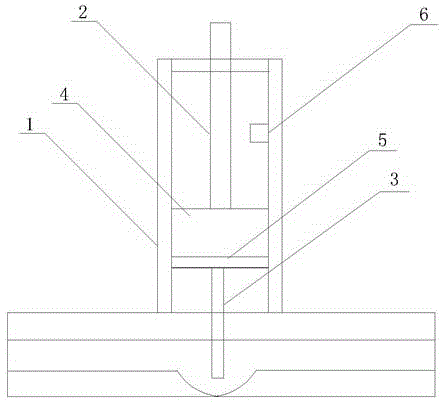

[0012] Such as figure 1 As shown, a hydraulic plate valve of the present embodiment includes a valve body 1, a valve stem 2 and a valve plate 3, the valve body 1 is provided with a space for accommodating the valve stem 2 and the valve plate 3, and the valve body 1 is additionally supplied with liquid or channels through which gases pass. The valve stem 2 is provided with a thread matched with the valve body 1, and the valve stem 2 and the valve body 1 rotate relative to each other through the thread, so that axial displacement occurs. The valve body 1 is provided with a hydraulic cavity 4, and the valve stem 2 is located in the hydraulic cavity 4 and sealed with the hydraulic cavity 4 by a sealing ring. The valve stem 2 and the valve plate 3 are connected by a pressure plate 5 , the pressure plate 3 is located at the bottom of the hydraulic chamber 4 , and the valve plate 3 is located at the bottom of the pressure plate 5 .

[0013] The hydraulic chamber 4 is in sealing con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com