Submarine pipeline clamp repair connector

A submarine pipeline and connector technology, applied in pipeline laying and maintenance, sleeve/socket connections, pipes/pipe joints/fittings, etc., can solve the cumbersome repair process, cannot achieve rapid repair, and hinders efficient and reliable submarine pipelines Repair and other problems, to achieve fast and reliable repair, flexible use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

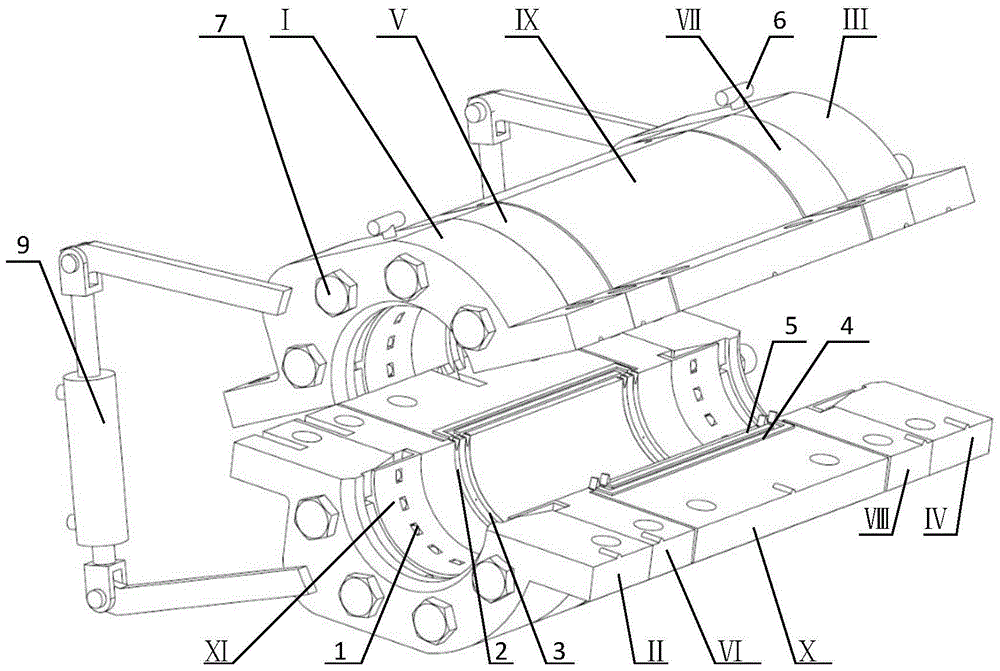

[0021] The present invention is described in more detail below in conjunction with accompanying drawing example:

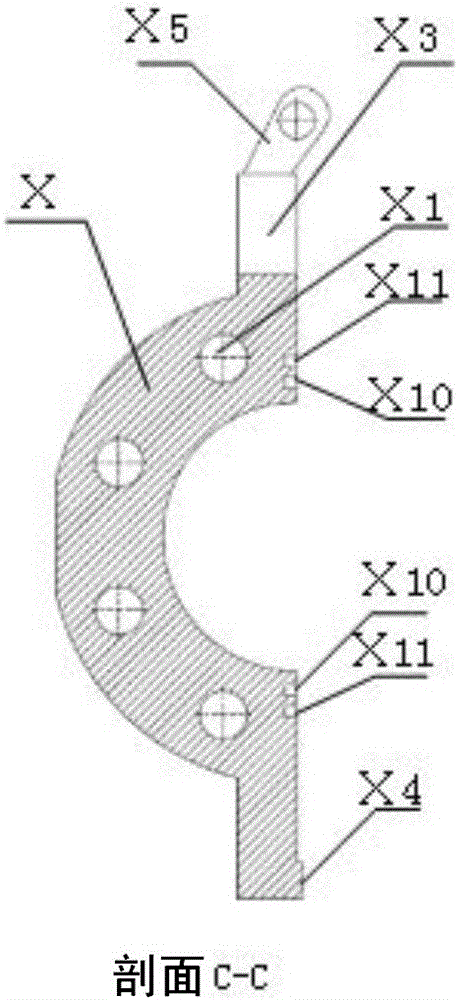

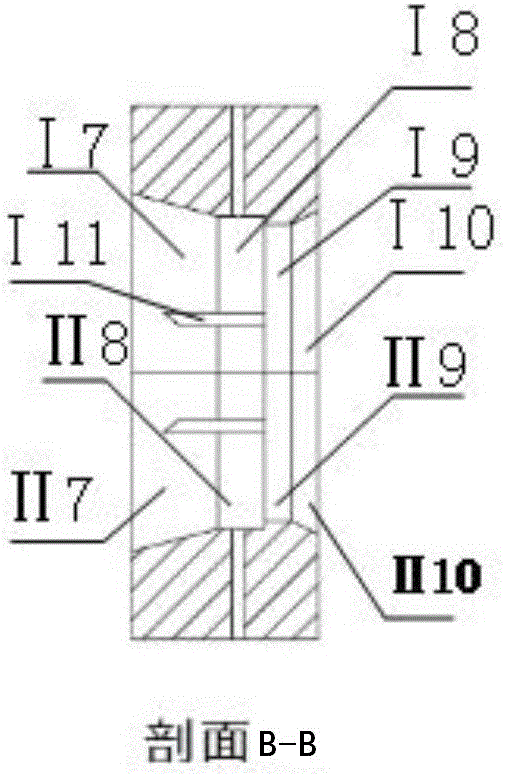

[0022] combine Figure 1-14 , the submarine pipeline clamp repair connector of the present invention, it is composed of grasping shell I, grasping shell II, grasping shell III, grasping shell IV, extruding shell V, extruding shell VI, extruding shell VII , extrusion shell Ⅷ, intermediate shell Ⅸ, intermediate shell Ⅹ, ball cage Ⅺ, ball cage positioning pin 6, spring 13, sealing ring 2, sealing ring spacer 3, steel ball 1, long bolt 7, nut 8, Short bolt 15, nut 14, hydraulic cylinder 9, secondary gasket 4, main gasket 5, housing alignment pin 11, housing connector 10.

[0023] 1. Grasping the shell Ⅰ is mainly composed of the shell alignment pin hole Ⅰ5, the concave surface Ⅰ6, 4 bolt holes Ⅰ1, 2 bolt holes Ⅰ2, the driving arm Ⅰ3, the ball cage positioning pin hole Ⅰ4, the cone surface Ⅰ7, the cylindrical surface Ⅰ8, It consists of a cylindrical surface I9, a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com