Novel tire-stripping-free tire repairing tool and using method thereof

A tire-free and tire-repairing technology is applied in the field of tire repairing, which can solve the problems of seal sleeve ulceration and sealing failure, and achieve the effects of preventing air leakage, good sealing performance and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

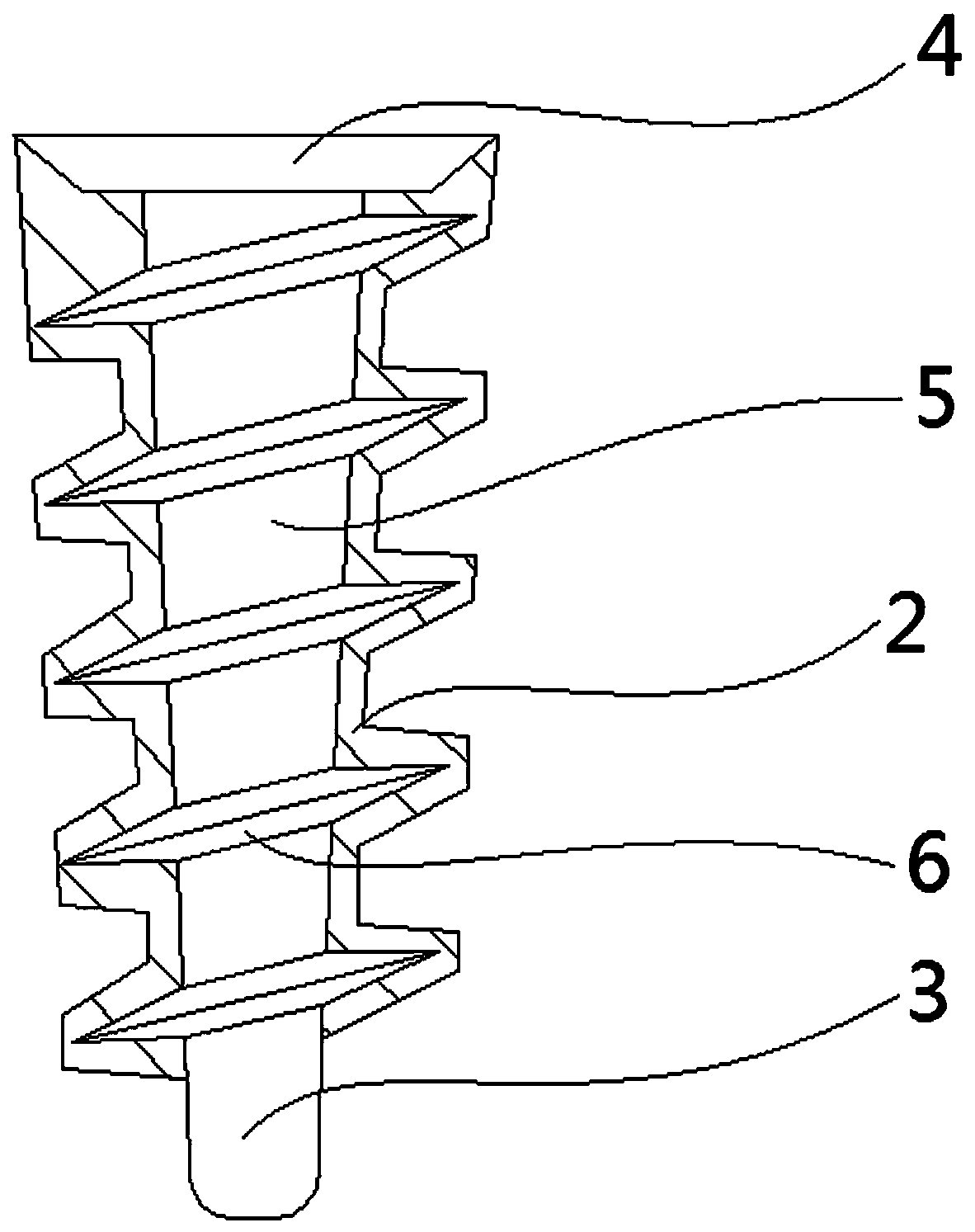

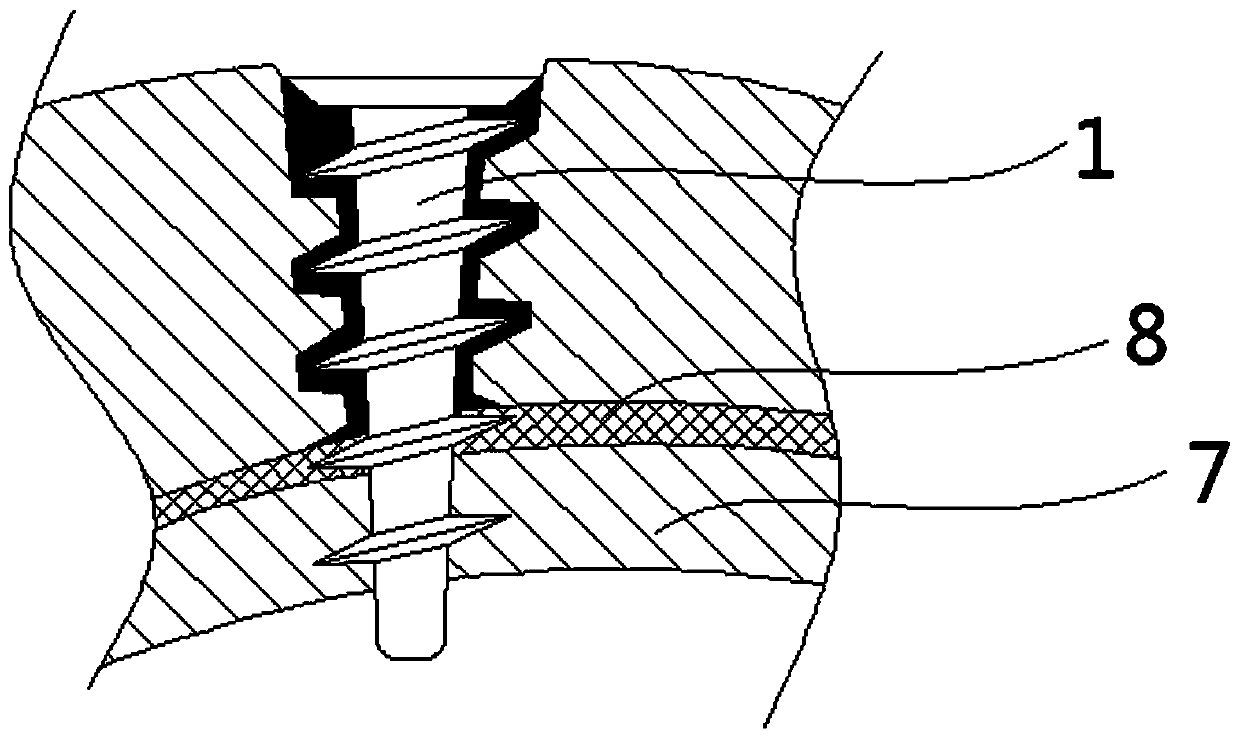

[0037] Embodiment one: see figure 1 As shown, a new type of tool for repairing a tire without picking up a tire includes a screw 1, see Figure 4 As shown, the surface of the screw 5 of the screw 1 is provided with a viscous film layer 2, the film layer 2 extends from the head of the screw to the screw area of the screw 2, the inner surface of the film layer 2 is in contact with the The surface of the screw rod 5 of the screw 1 is bonded.

[0038] In this embodiment, the screw head 4 is in the shape of a truncated cone, and the diameter of the outer surface is larger than the diameter of the inner surface.

[0039] In this embodiment, the thickness of the screw head 4 is 1.1 mm, 1.3 mm or 1.5 mm, and the screw head 4 is thinned to further increase the length of the thread and improve the repair space.

[0040] In this embodiment, the maximum diameter of the outer surface of the head of the screw 1 (that is, the maximum diameter of the outer surface of the frustum-shaped st...

Embodiment 2

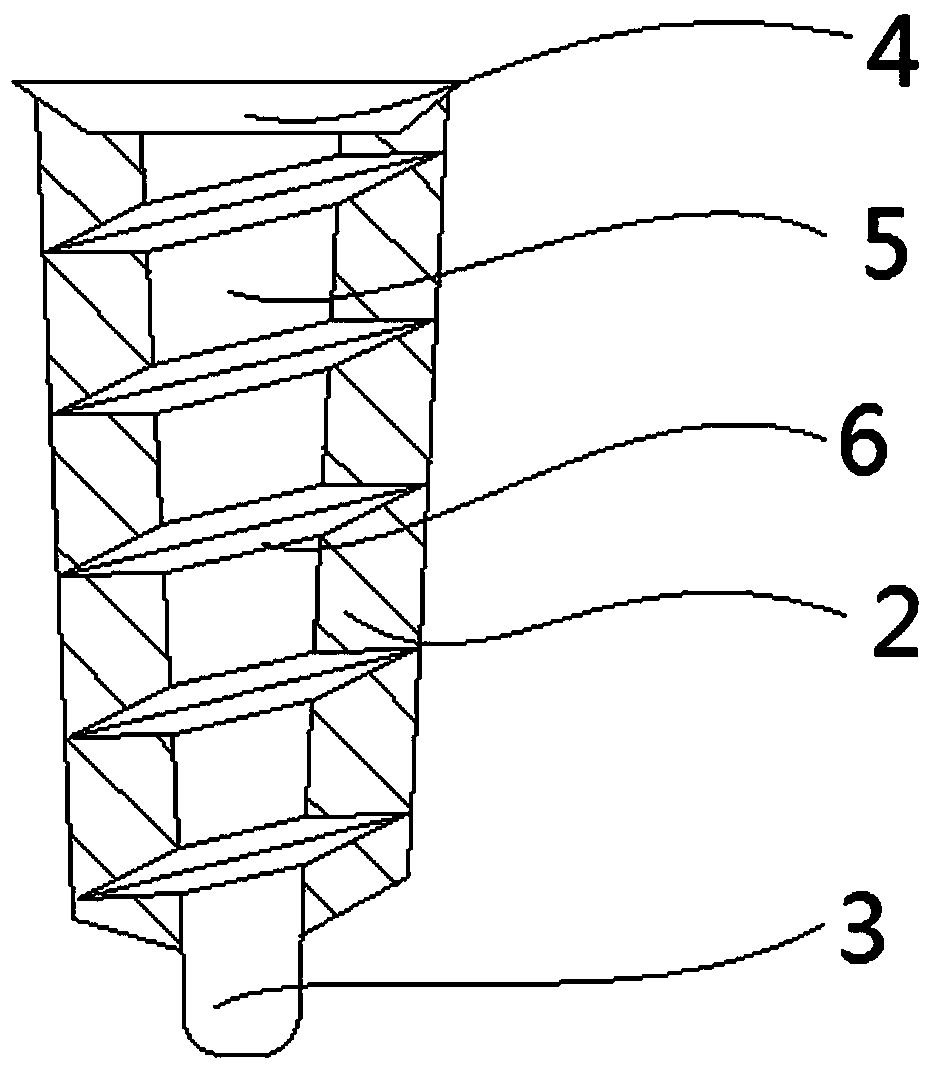

[0061] Embodiment two: see figure 2 As shown, a new type of tire-repairing tool without pick-up includes a screw 1, the surface of the screw 5 of the screw 1 is provided with a sticky film layer 2, and the film layer 2 extends from the head of the screw to the screw 2. The screw area of the screw extends, and the inner surface of the adhesive film layer 2 is bonded to the surface of the screw 5 of the screw 1.

[0062] In this example, see figure 2 As shown, the adhesive film layer 2 is wrapped and bonded on the screw rod, and generally has a conical structure.

[0063] In this embodiment, the thickness of the screw head is 1.2 mm, that is, the thickness of the frustum-shaped structure is 1.2 mm. The screw head is thinned, the length of the thread is further increased, and the repair space is improved. In this embodiment, the diameter of the outer surface of the head of the screw 1 is 5.5 mm, and the diameter of the head of the screw 1 is reduced to facilitate screwing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com