Condensate heat recovery method using double flashing and pressurizing

A recovery method and condensed water technology, applied in lighting and heating equipment, steam generation, etc., can solve the problems of low heat utilization rate and energy waste of condensed water, and achieve the effects of wide application, high steam value and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1: Modification of the condensed water heat recovery system in a catalytic cracking unit of an oil refinery.

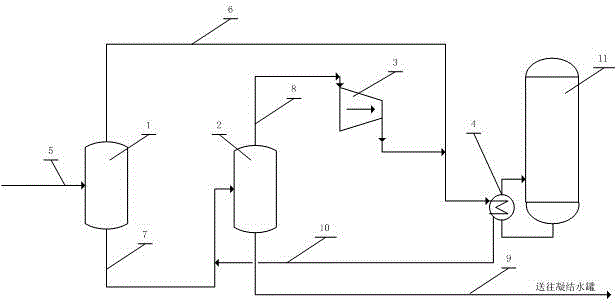

[0017] Such as figure 1 As shown, the original process is that high-temperature condensate 5 with a pressure of 0.6 MPaG and a flow rate of 40 t / h directly enters the condensate tank. After the transformation, the high-temperature condensate 5 enters the primary flash tank 1 first, and the primary flash steam 6 with a pressure of 0.3MPaG is flashed out, and the primary condensed water 7 enters the secondary flash tank 2 for secondary flash evaporation, and the flash pressure is The secondary flash steam 8 of 0.1MPaG, the secondary flash steam 8 enters the vapor compression equipment 3, the pressure after compression is 0.3MPaG, and the primary flash steam 6 of the same pressure enters the heat exchanger 4 together to provide a heat source for the separation tower 11. The heated condensate 10 and the primary condensate 7 are used as the feed of the seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com