Direction control device, casing pipe conveying device and method and concentricity measuring device

A technology for direction control and transporting devices, applied in the direction of measuring devices, optical devices, instruments, etc., to achieve the effect of suppressing positional deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

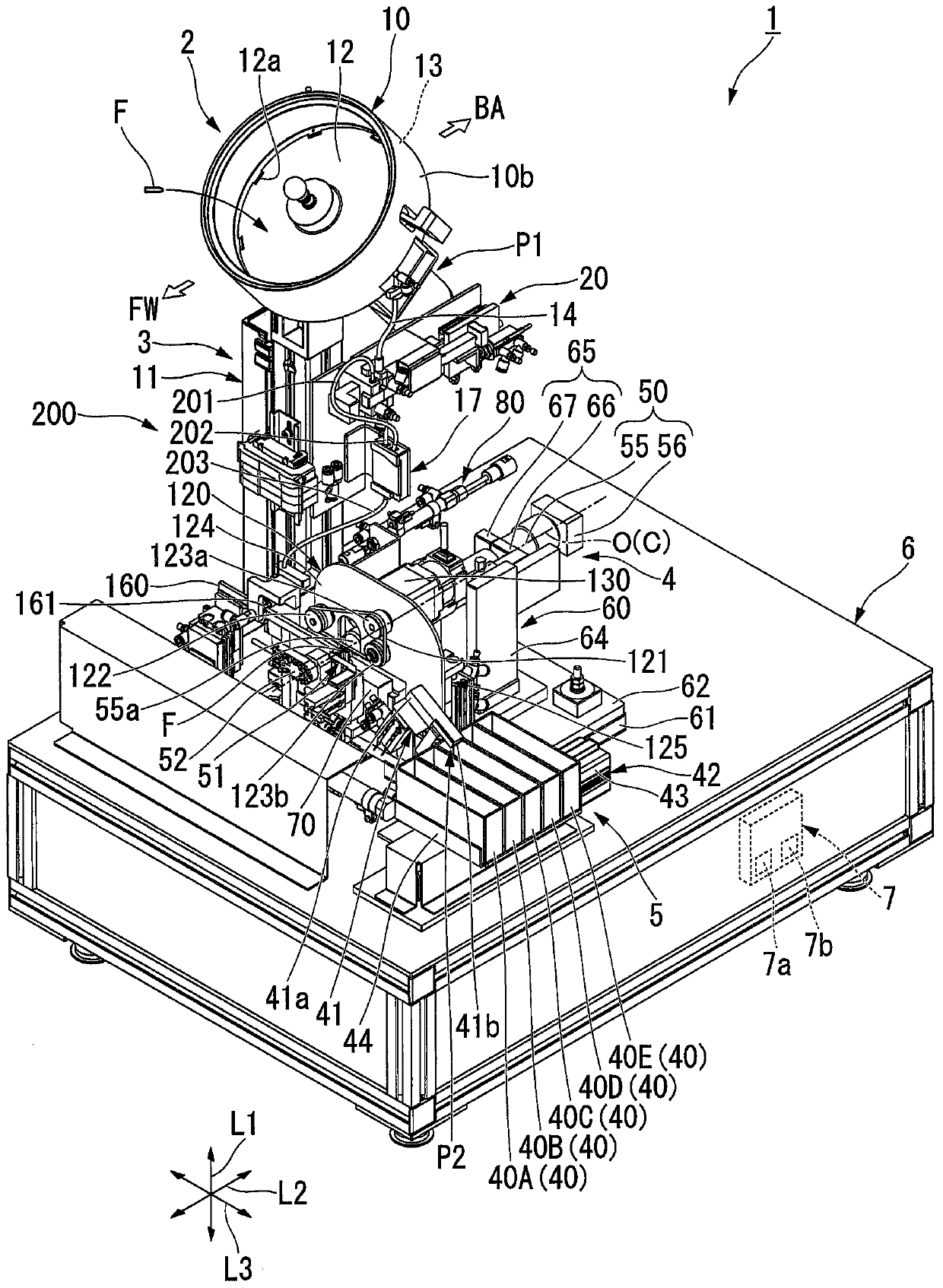

[0069] figure 1 It is a diagram showing an embodiment of the bushing concentricity measuring device of the present invention, and is a schematic configuration diagram of the whole.

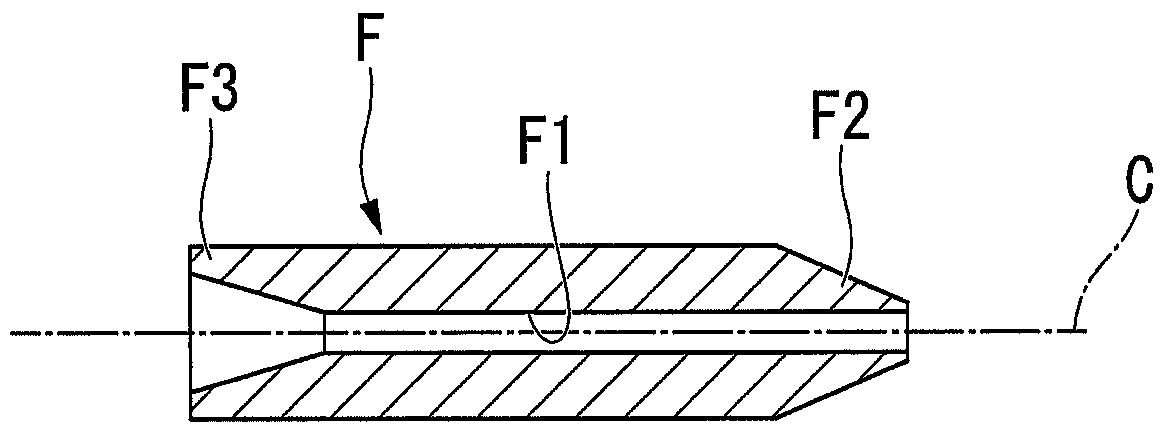

[0070] Such as figure 1 As shown, the bushing concentricity measurement device 1 of this embodiment is a device that photographs a plurality of bushings F (corresponding to "workpieces" in the claims) one by one, and performs bushing based on the captured images. The concentricity of F is measured and stored in the storage box 40 while being classified into quality grades based on the measurement results.

[0071] figure 2 yes figure 1 The overall perspective view of the casing concentricity measuring device shown.

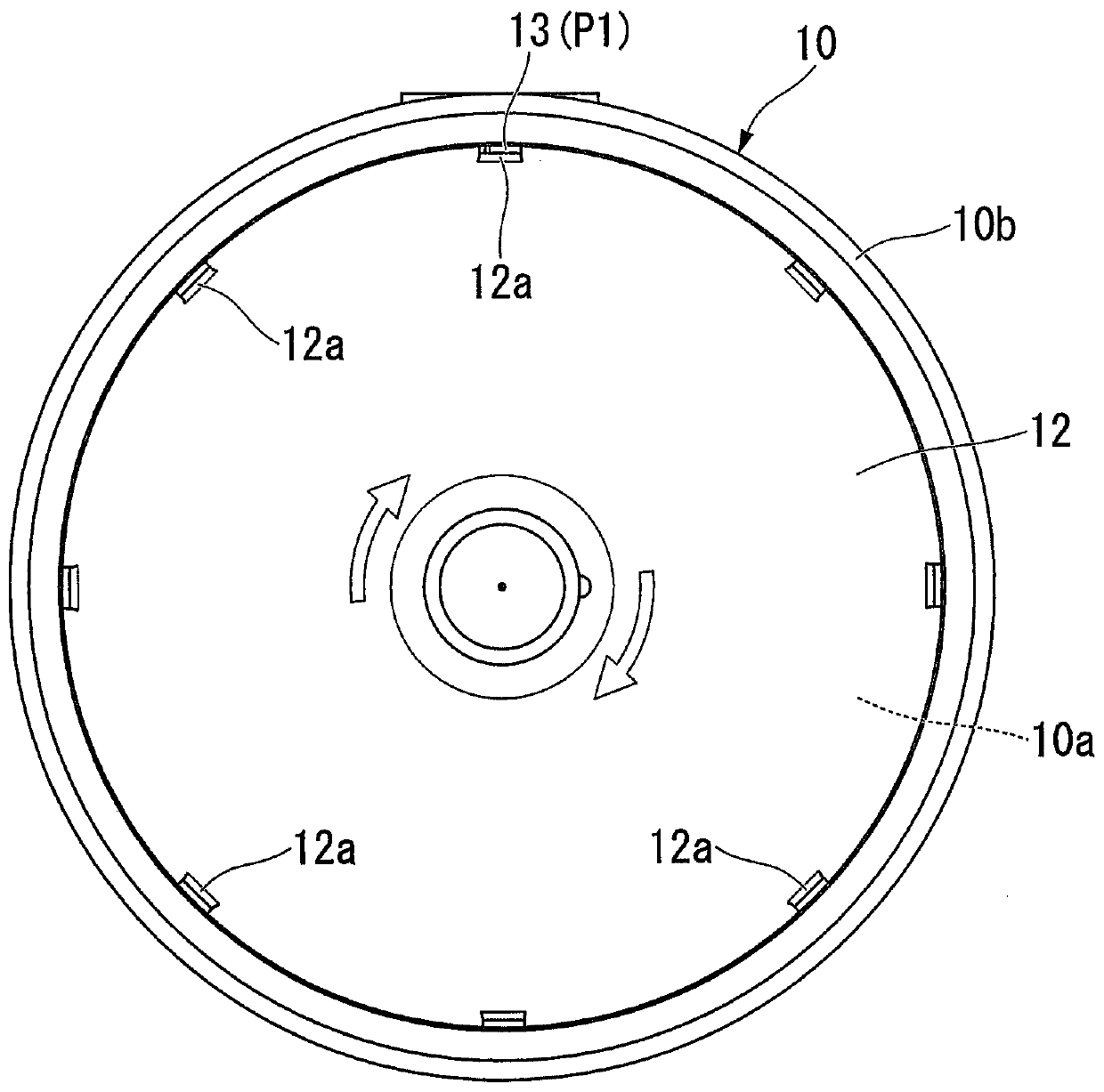

[0072] The casing concentricity measurement device 1 includes: a casing supply device 2; a casing transport device 3 having a direction control device 20; a casing imagin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com