A rear axle torsional fatigue unilateral random spectrum loading test tool and its test method

A technology of loading test and torsional fatigue, applied in the field of fatigue test, can solve the problems of high test cost, long preparation time and low cost, and achieve the effect of high test assessment accuracy, simple tooling structure and short preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

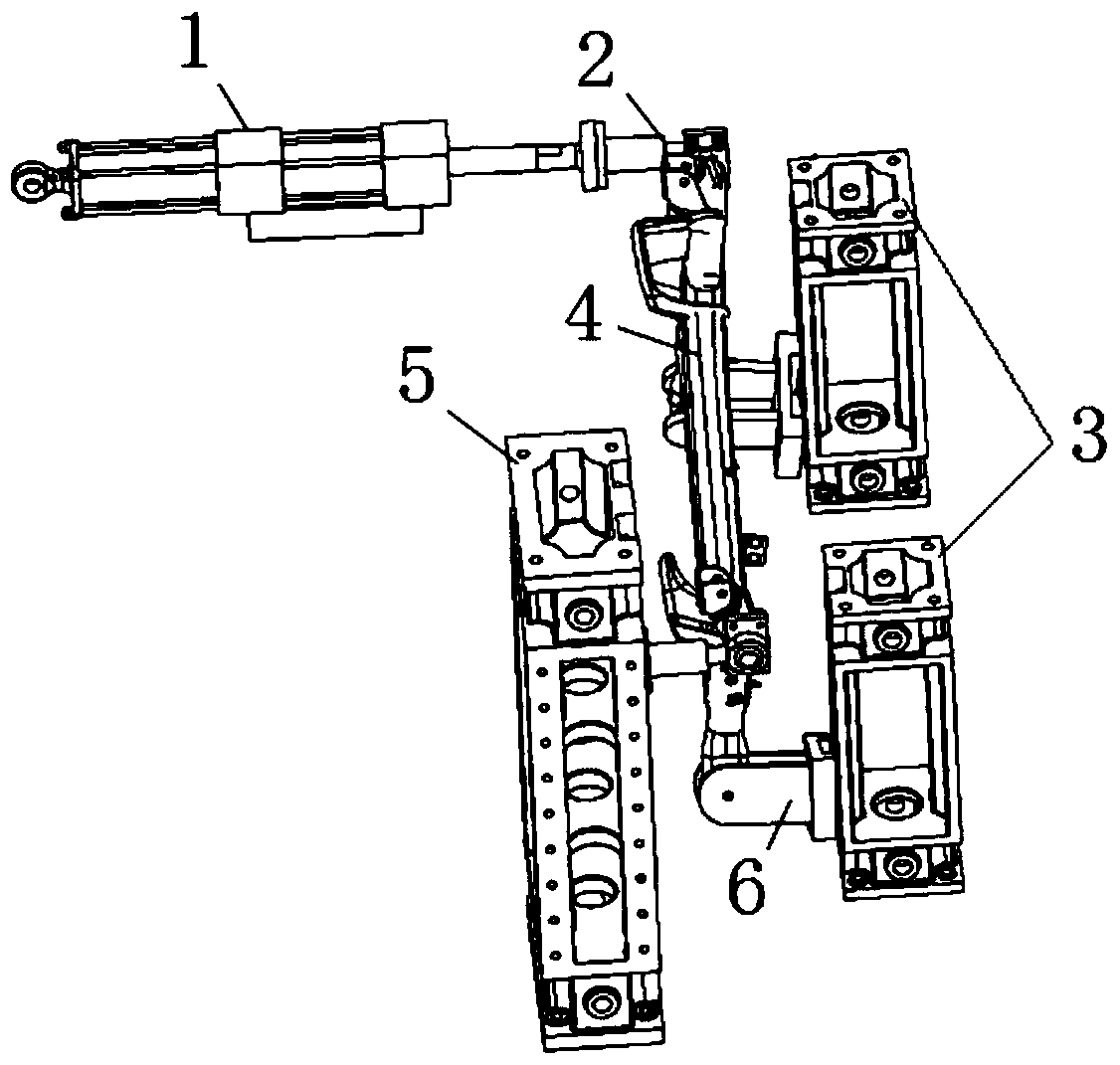

[0023] Such as figure 1 As shown, the rear axle torsional fatigue unilateral random spectrum loading test fixture includes a combined bracket, a hydraulic cylinder 1 and two swing bolts 2, wherein the combined bracket is a frame structure with high structural strength.

[0024] The combined bracket includes combined bracket I3 and combined bracket II5, and combined bracket I3 and combined bracket II5 are respectively located on both sides of the rear axle welding assembly 4; wherein, combined bracket I3 is two independent brackets arranged side by side, and the two independent brackets are respectively connected to The two ends of the rear axle welding assembly are corresponding.

[0025] The combined bracket II5 is connected to the place where the hub axle is installed at one end of the rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com