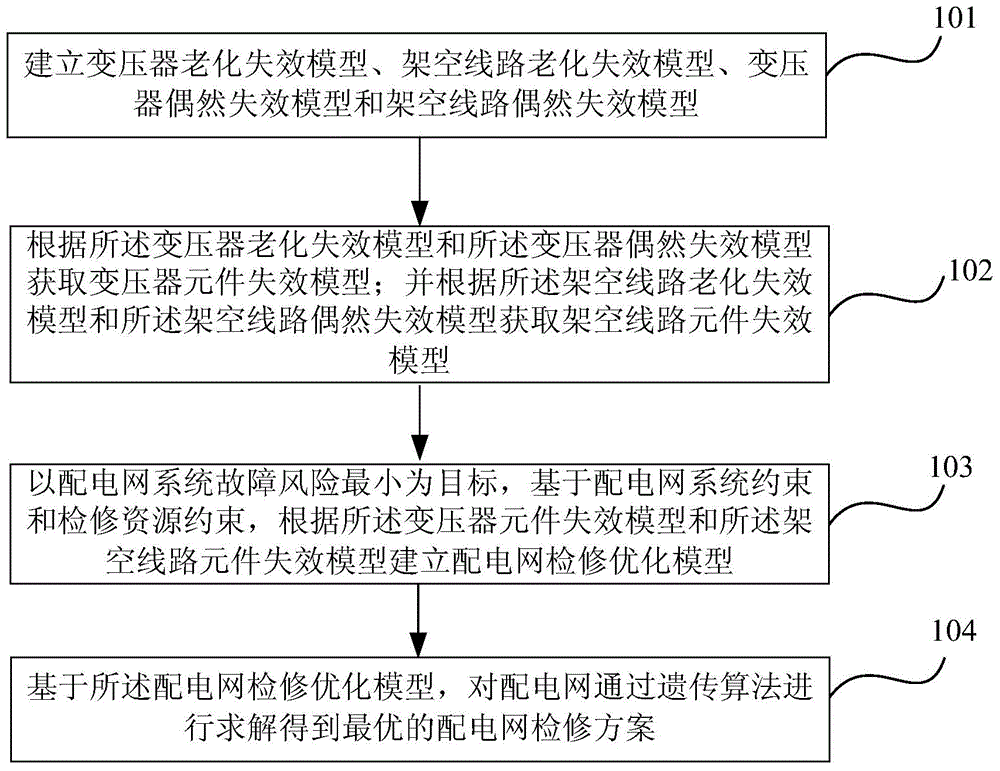

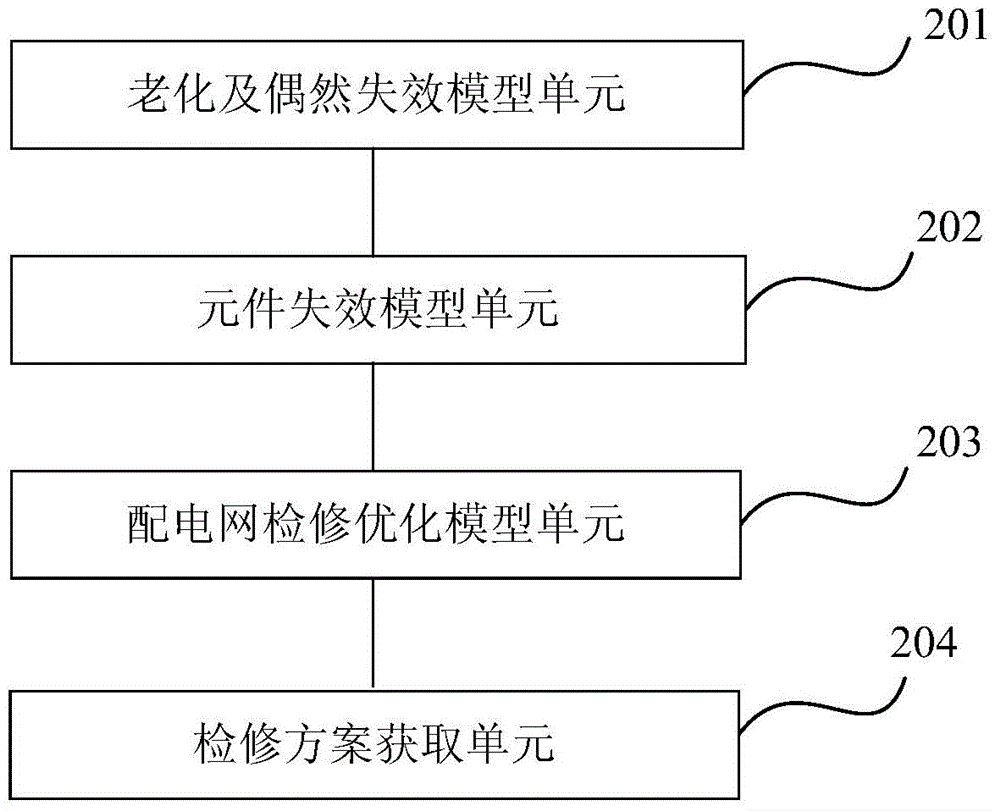

Distribution network maintenance scheme optimization method and device based on element failure model

A failure model and distribution network technology, applied in the field of power system, can solve problems such as failure to achieve power supply reliability and maintenance economy, potential fault analysis and modeling, and multiple maintenance tasks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

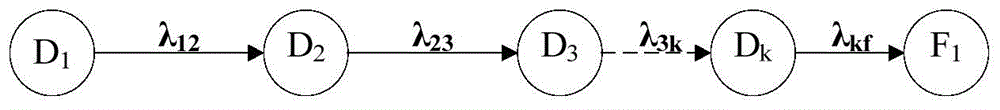

[0068] During the operation of components, the reasons for their failure and outage can be divided into two categories: natural aging and random factors. The former refers to the internal aging of equipment, such as the loss of mechanical and electrical functions of internal solid insulating materials and insulating oil for transformers; the latter refers to accidental factors such as operating conditions (such as external weather). Therefore, the component failure model includes the component aging failure model and the accidental failure model, which comprehensively considers the influence of component aging and operating conditions on the component operating state.

[0069] The aging process of components consists of k stages of continuous change, expressed as starting from D 1 to D k . After the kth aging state, the component will reach the failure state F if there is no overhaul 1 . After a component fails, repairs are required to restore the component to its initial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com