Commutator

A technology of commutator and commutator segment, applied in the field of commutator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

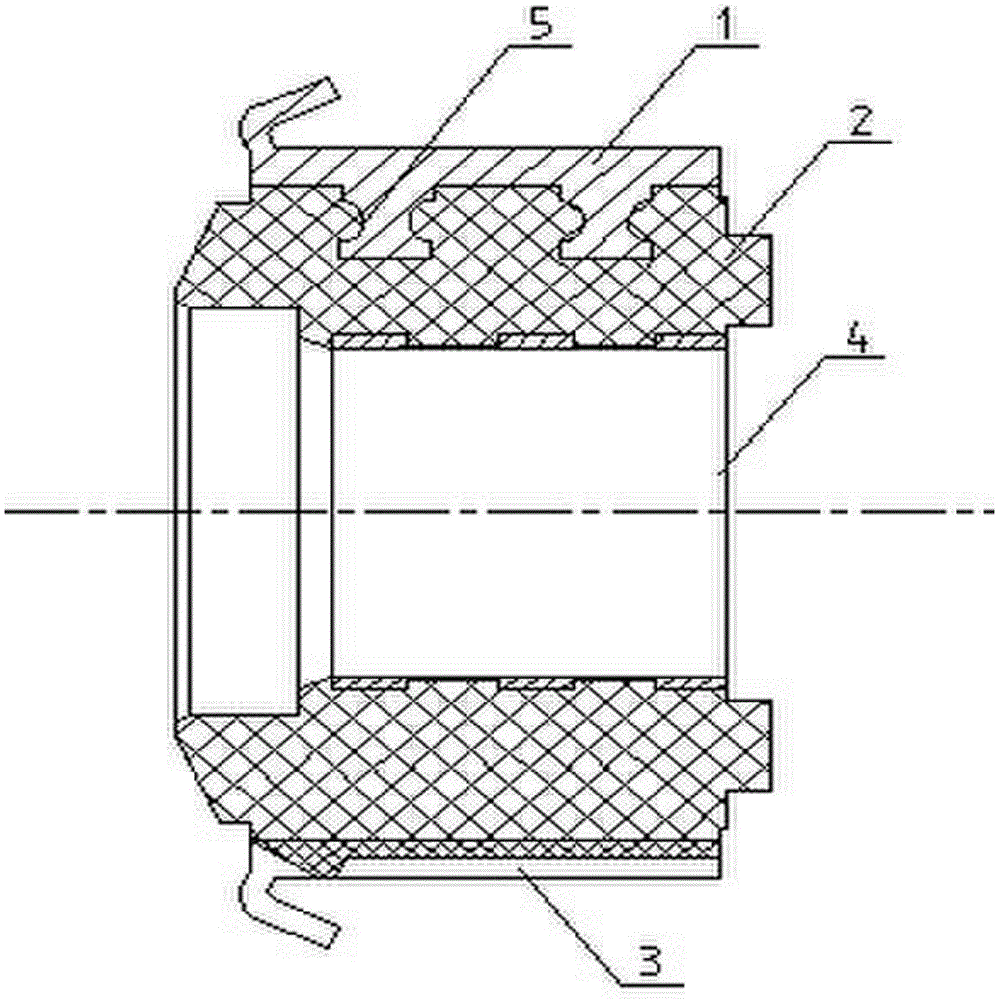

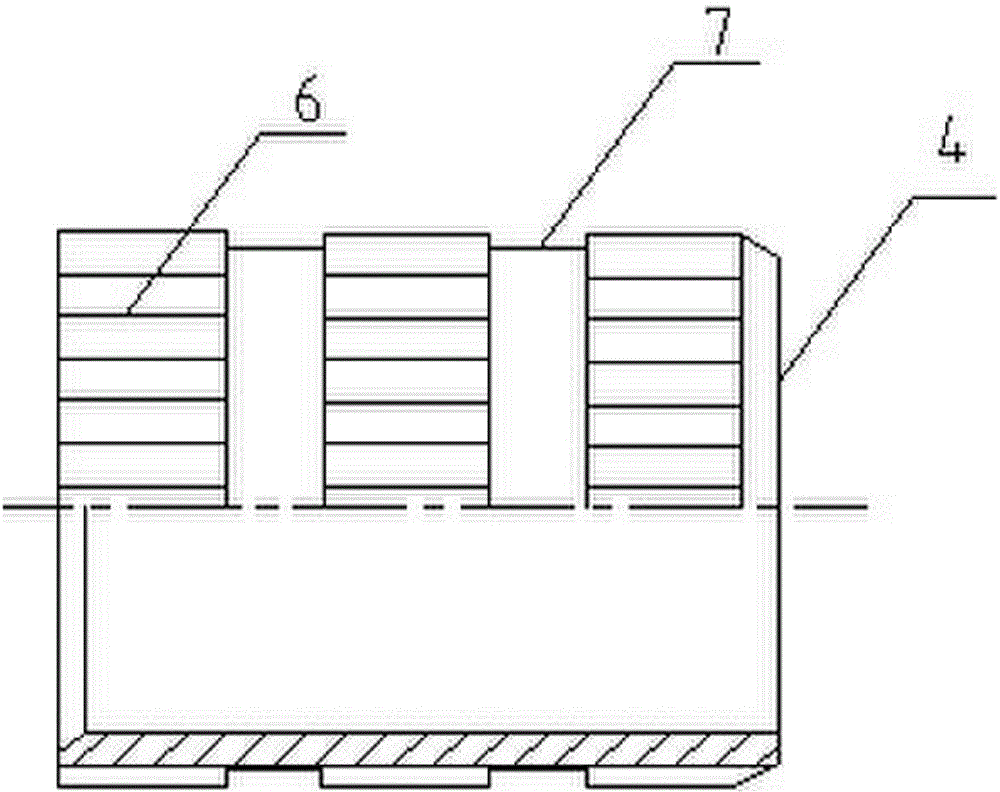

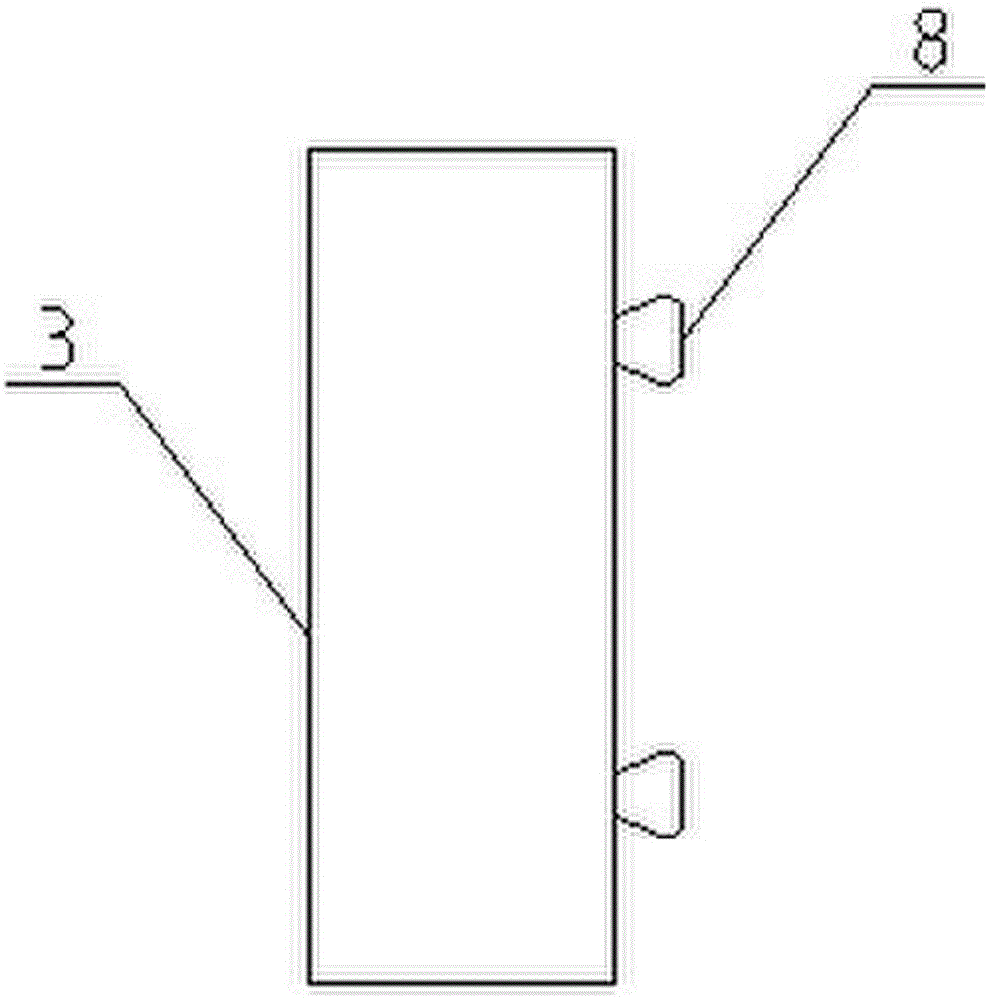

[0013] Such as Figure 1 to Figure 3 The commutator shown includes commutator segment 1, bushing 4, molding compound 2 and mica sheet 3. After preheating, molding compound 2 is quickly applied under high temperature and high pressure to make it flow into commutator segment 1 and bushing 4, after the molding compound 2 is cured, the commutator piece 1, the molding compound 2 and the bushing 4 are firmly combined, the mica piece 3 is arranged between the commutator piece 1, and the commutator piece 1 pin The part 5 has a centrally symmetrical arch bridge structure, that is, the foot part 5 of the commutator piece 1 has an arch bridge structure with its vertical and horizontal centerlines as axes, left and right, and up and down. The contact area with the molding compound 2 makes the contact strength between the two reliable, the adhesion is improved, and the phenomenon of flying and jumping of the commutator piece 1 is prevented. The commutator piece 1 is made of silver-copper a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com