Dosing system, dosing method and production method

A dosing and control unit technology, applied in dosing systems, dosing and manufacturing fields, can solve problems such as high-precision dosing of unsuitable dosing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

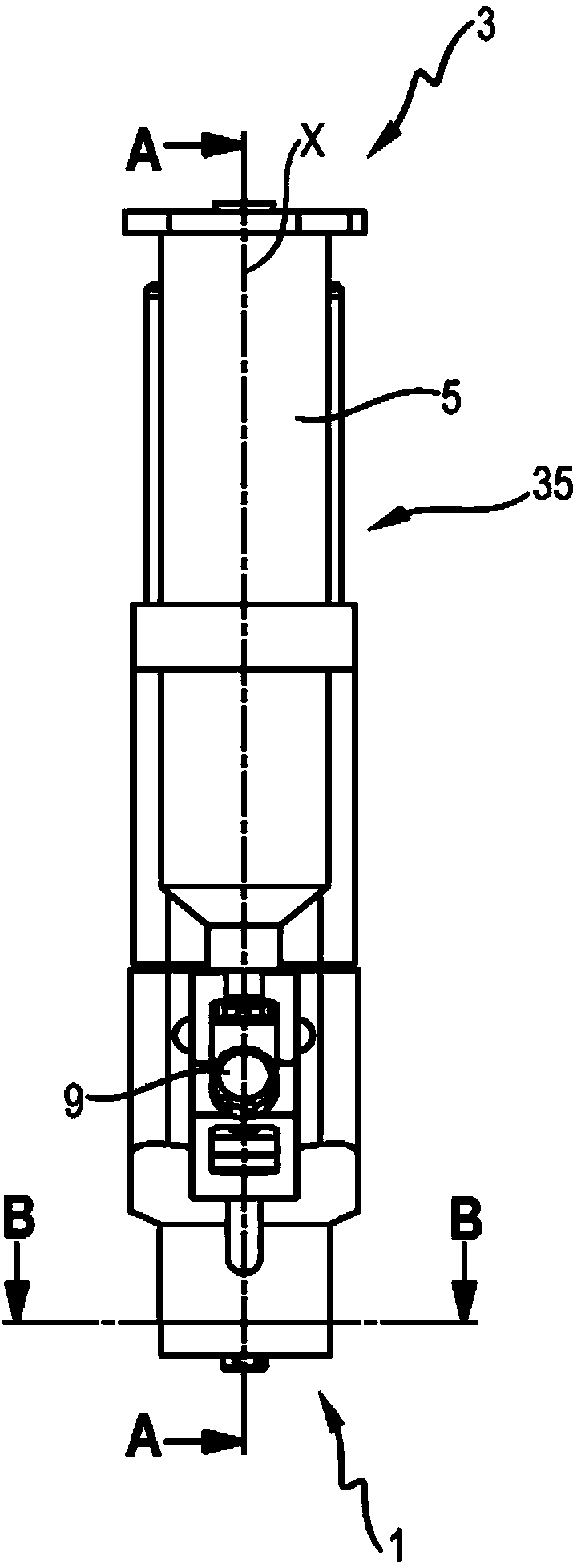

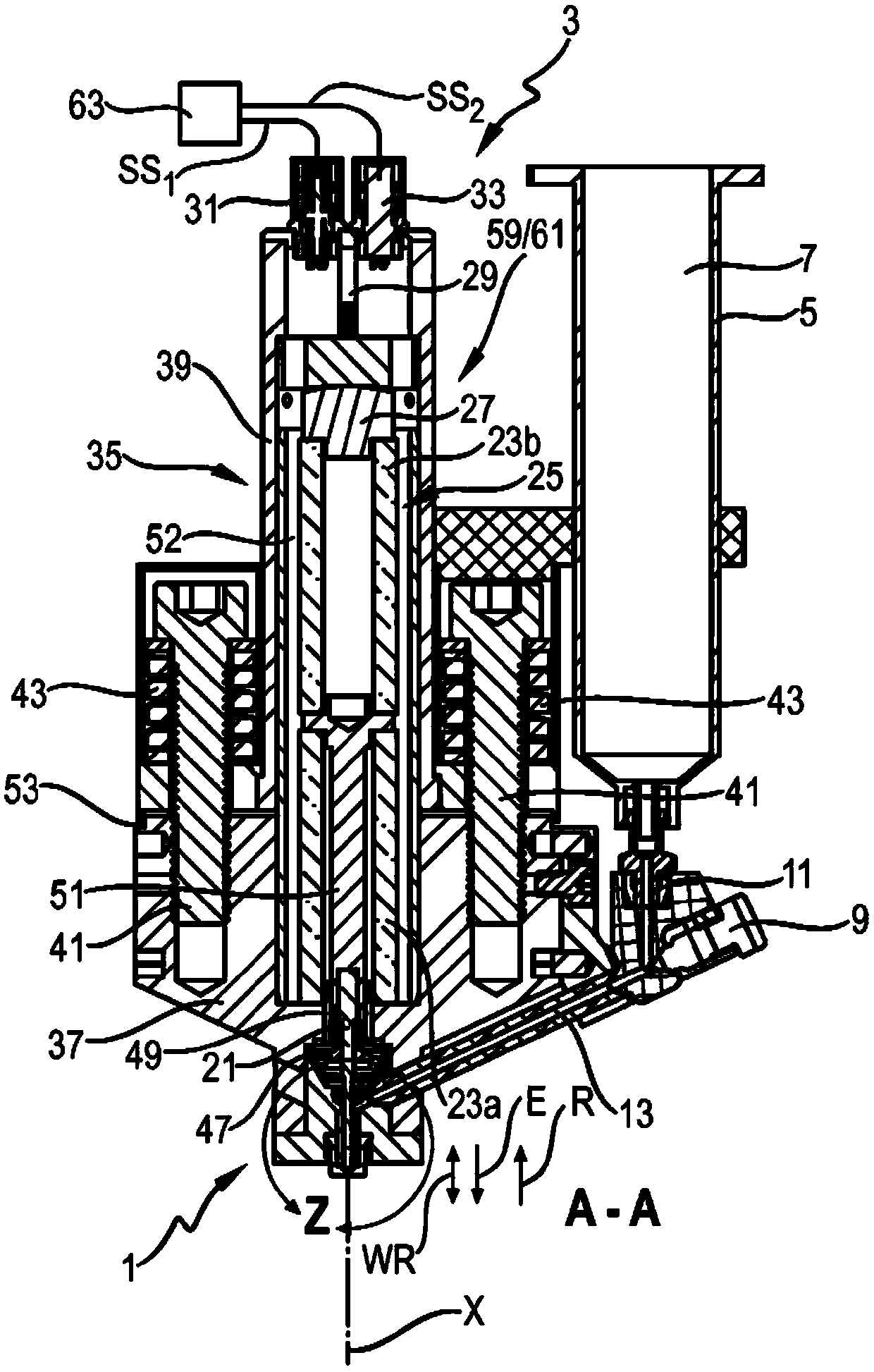

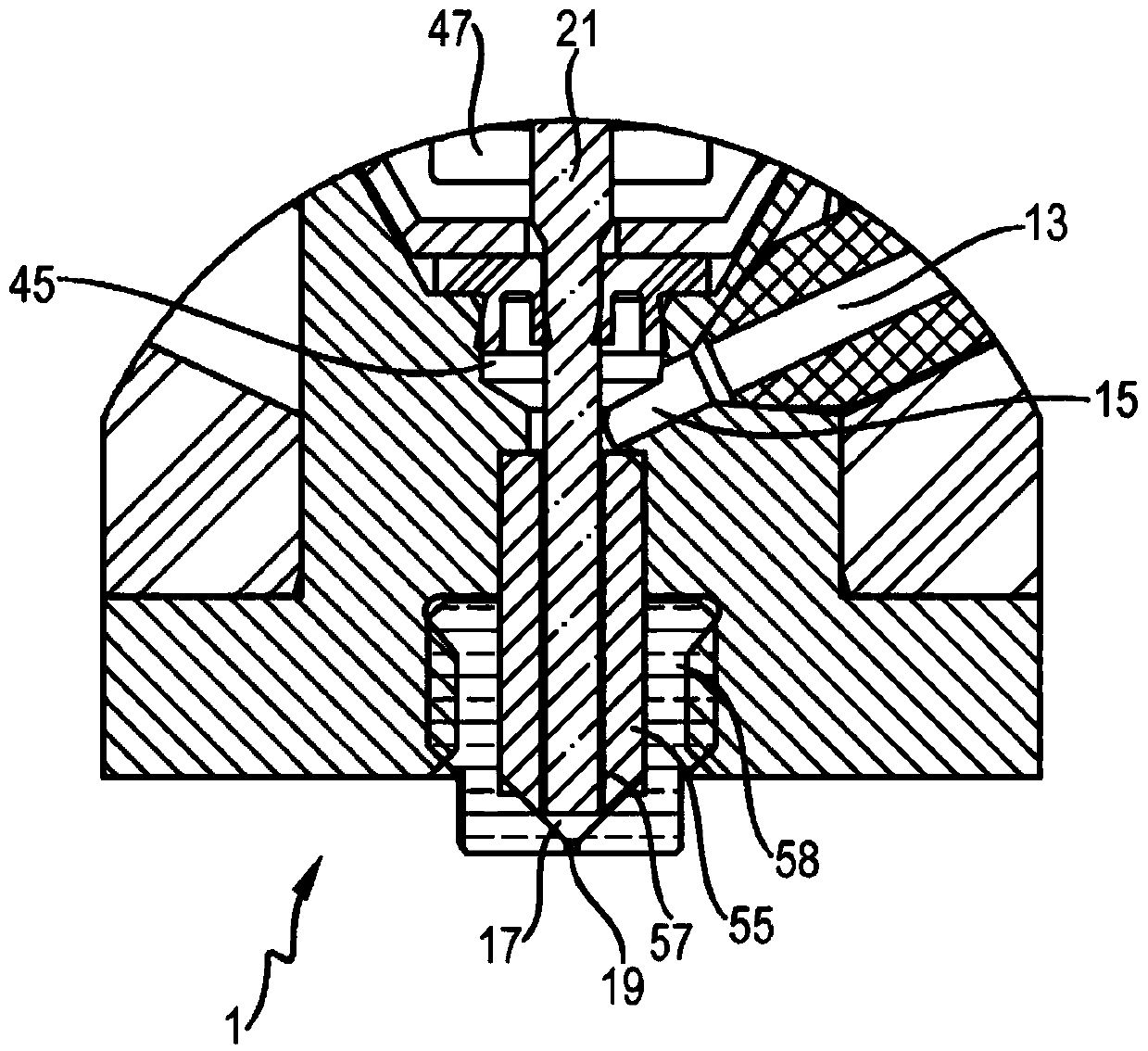

[0066] figure 1 and figure 2 shows a dosing system 3 according to one embodiment of the invention, image 3 for figure 2 detailed view of the . The metering system 3 comprises a nozzle 1 , a metering material container 5 with a metering material reservoir 7 and a housing 35 , wherein an actuator chamber 25 is provided in addition to the nozzle 1 .

[0067] The housing 35 comprises a lower first housing part 37 and an upper second housing part 39 . The two housing parts 37 , 39 are resiliently connected to each other via a fastening screw 41 and a vertically oriented spring 43 connected to the fastening screw 41 . This results in a gap 53 , ie a certain clearance, on both sides at the edge between the two housing parts 37 , 39 .

[0068] In the housing 35 , the actuator chamber 25 is arranged centrally in an actuation region 59 . The first piezoelectric actuator 23a and the second piezoelectric actuator 23b are aligned in the direction of the (middle) axis X and positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com