Lifting-type corn straw picking device with wheel belt

A corn stalk and lifting technology, applied in the field of agricultural machinery, can solve the problems of affecting seeding, high missed detection rate, and excessive impurities in straw, so as to increase the picking rate, facilitate transportation, and reduce energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

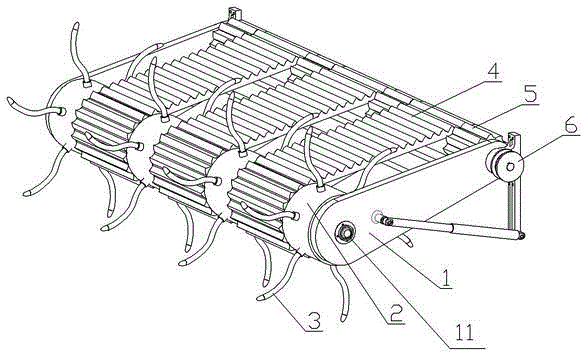

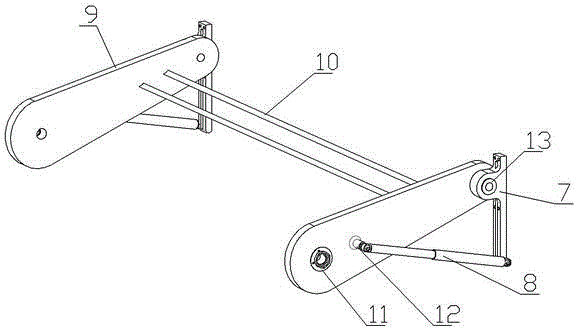

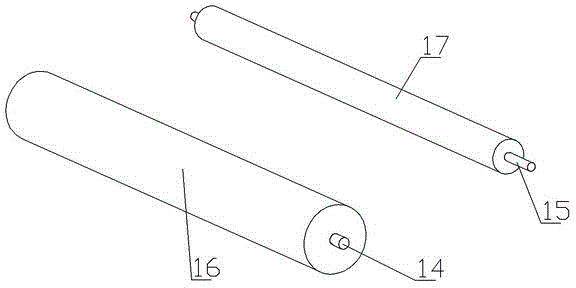

[0021] see figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the present invention includes a frame 1, a pick-up wheel 2, a pick-up tooth 3, a conveyor belt 4, a limit wheel 5, a pulley 6, a front axle 14, a rear axle 15, a front axle rubber cylinder 16 and a rear axle steel cylinder 17, The pick-up teeth 3 are evenly distributed on the outer circumference of the pick-up wheel 2, the pick-up wheel 2 and the conveyor belt 4 are installed on the front axle rubber barrel 16 at intervals, the limit wheel 5 and the conveyor belt 4 are installed on the rear axle steel barrel 17 at intervals, and the front axle rubber barrel 16 is hinged on the front bearing housing 11 through the front axle 14, the rear axle steel cylinder 17 and the pulley 6 are fixed on the rear axle 15, and the rear axle steel cylinder 17 is hinged on the side plate rear axle sleeve 13 through the rear axle 15; 1 includes a frame seat 7, an oil cylinder 8, a side plate wall 9, a side plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com