Selective laser melting device

A laser melting and selective technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of loss, scrapped processing parts, material waste, etc., to prevent hard collision, avoid material waste, and avoid scraper damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

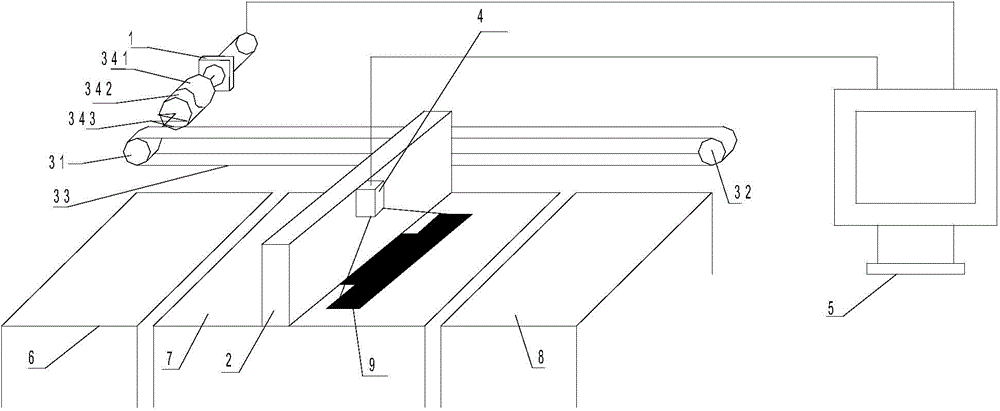

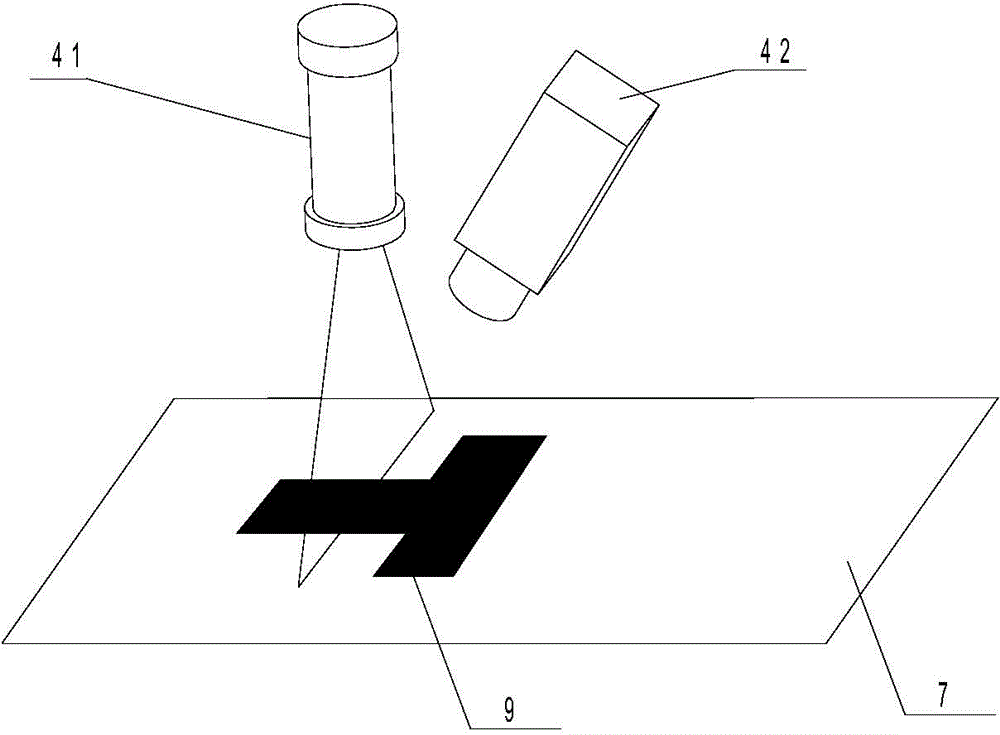

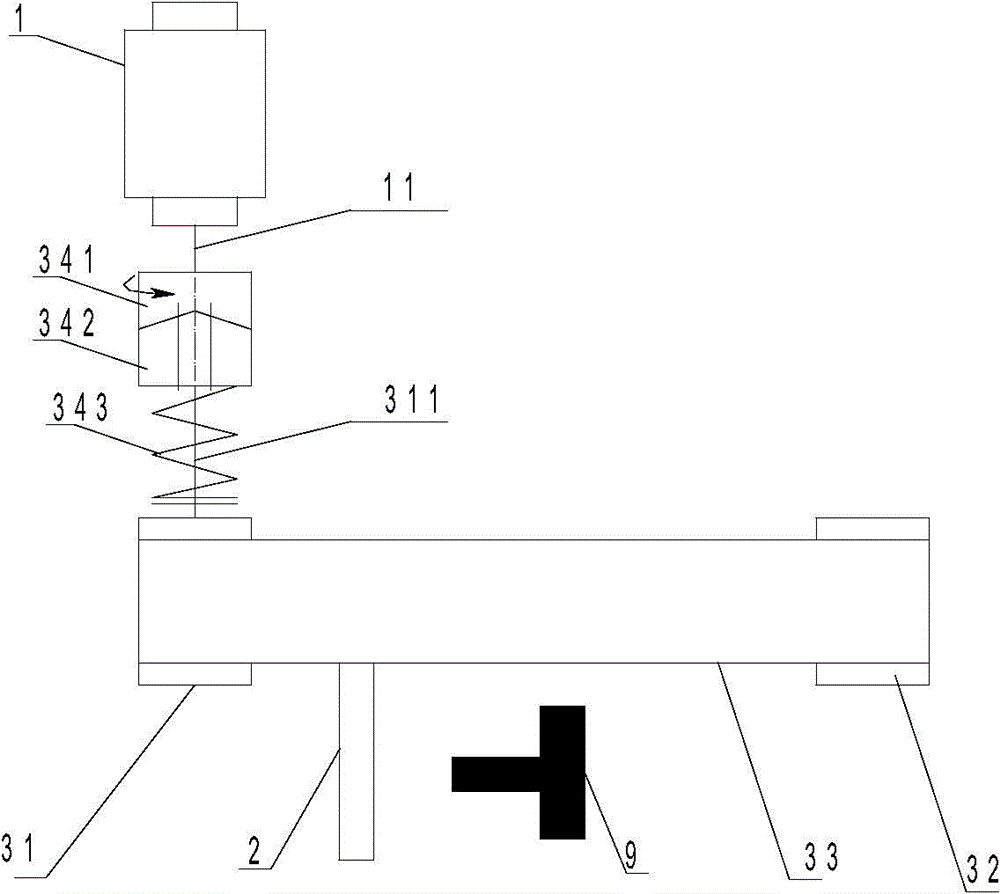

[0020] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a structural schematic diagram of the flatness detector of the present invention, image 3 It is a structural schematic diagram of the transmission mechanism of the present invention, as shown in the figure: the selective laser melting device of the present invention includes a motor 1, a scraper 2 and a transmission mechanism for transmitting the power of the motor 1 to the scraper 2, and also includes Flatness detector 4 and computer 5, described flatness detector 4 detects the flatness of the upper layer of molded part 9 and transmits the flatness data to computer 5 in the scraper 2 powder spreading process; The data is processed and sends a stop signal to the motor 1 after detecting the warping signal, so that the scraper 2 stops the powder spreading movement; the computer 5 can be a single-chip microcomputer, which has information receiving, processing and sending functions, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com