Numerical Control Machining Method of Tenon and Groove Chamfering

A processing method and tongue-and-groove technology, which is applied to the processing of roulette tongue-and-groove fillets, can solve the problems of high labor intensity of operators, poor chamfering position consistency, low surface precision, etc., so as to solve the problem of low processing efficiency and ensure processing. Quality, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1 A numerical control machining method for the chamfering of the straight tenon and groove of the aero-engine wheel

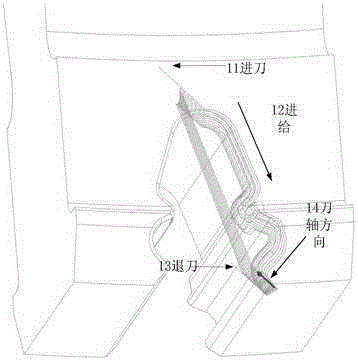

[0040] Its numerical control processing method, steps, such as figure 1 Shown:

[0041] Step 1 analyzes the overall structure of the aeroengine wheel disc of embodiment 1

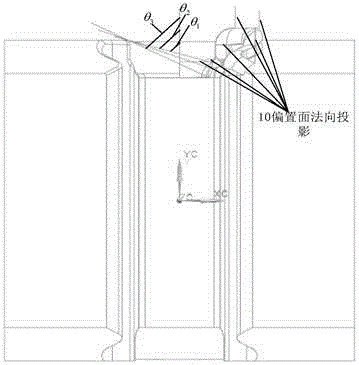

[0042] figure 2 It is the overall structure of embodiment 1 aeroengine wheel disk, among the figure: A 1 ,A 2 ,A 3 ...A n , B 1 ,B 2 ...B n is the processing sequence of the chamfering positions on both sides; 1 is the tenon groove on the wheel; α is the angle between adjacent tenon grooves.

[0043] image 3 It is the shape and structure of the tenon and groove 1 of the wheel disk in Example 1, and the chamfering position is a non-smooth continuous area: 3 and 4 are respectively the chamfering sides 3 (side A) and 4 (side B) corresponding to both sides of the tenon and groove, and 2 is the 3 Another tongue and groove chamfering edge on the same side;

[0044] F...

Embodiment 2

[0058] Embodiment 2 A numerical control machining method for the chamfering of the oblique tenon and groove of the aero-engine wheel

Embodiment 2

[0059] The main difference between the chamfering position of the tenon and groove in Example 2 and that in Example 1 is: the chamfering position of the tenon and groove in Example 1 image 3 The middle positions 3 and 4 are symmetrical, and the structural dimensions of the chamfering positions of the two end faces of the blisk in Example 1 are the same, while the chamfering positions of the tongue and groove in Example 2 are asymmetrical.

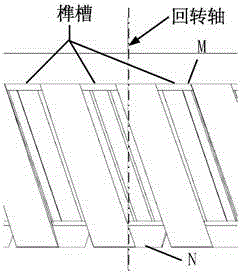

[0060] Figure 11 It is the tongue and groove structure diagram of embodiment 2, Figure 12 It is the structural diagram of the M side chamfering position of the mortise groove of embodiment 2, Figure 13 It is a structural diagram of the chamfering position of the N side of the mortise of the embodiment 2. Each tongue and groove of this embodiment ( Figure 11 The two end faces of M and N) have different structural dimensions, and because the mortise is inclined, both sides of the mortise on the M end face ( Figure 12 position P 1 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com