Axle balance control system of self-propelled high-altitude operation vehicle

A high-altitude operating vehicle and balance control technology, which is applied in the interconnection system, vehicle components, suspension, etc., can solve the problems of insufficient driving force of the vehicle and the inability of the driving wheels to touch the ground at the same time, to achieve reliable locking, improve reliability, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

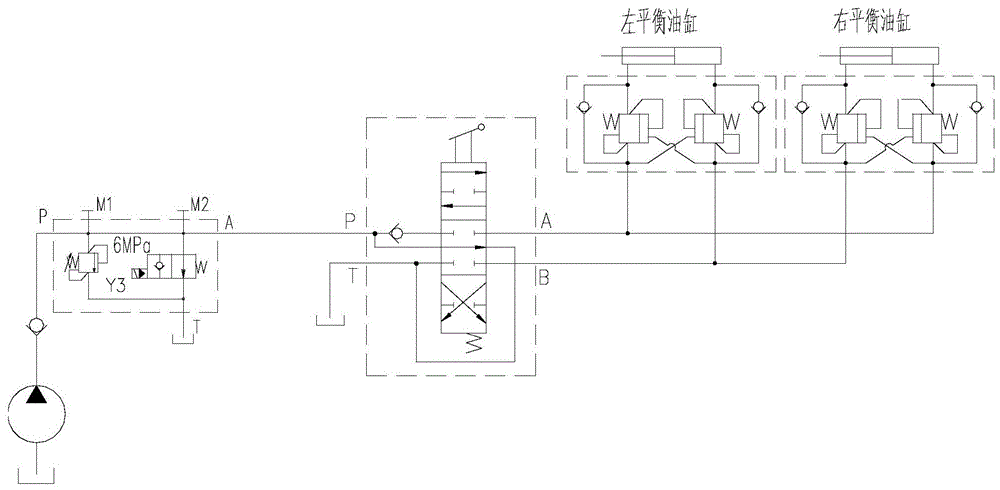

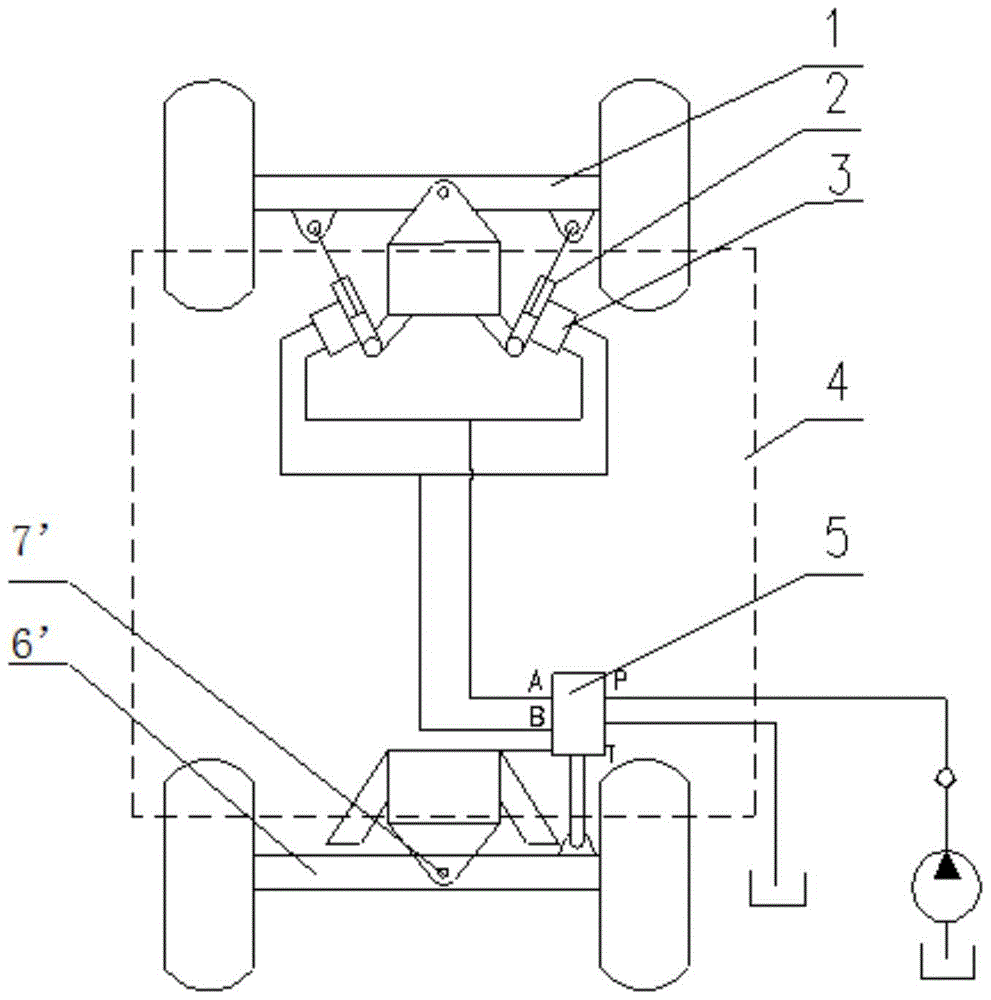

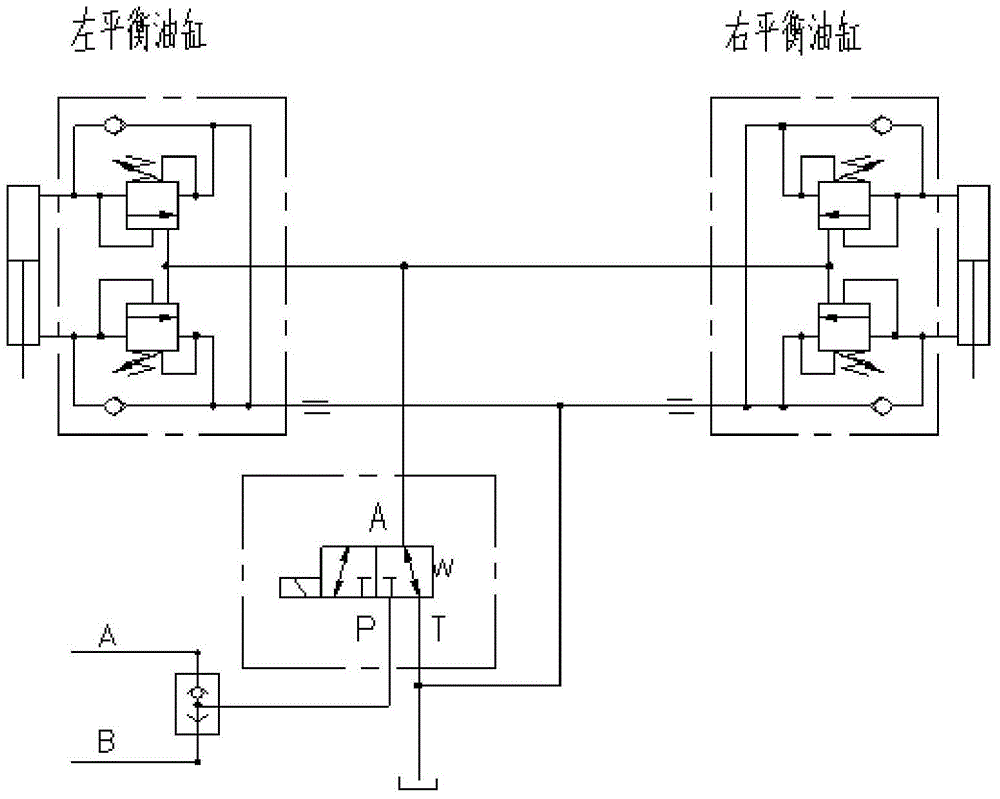

[0022] refer to Figure 3-4 , the specific embodiment adopts the following technical solutions: self-propelled aerial work vehicle axle balance control system, mainly including front axle 1, balance oil cylinder 2, balance valve 3, vehicle frame 4, solenoid valve 5, shuttle valve 6, rear axle 7. Both ends of the two balance oil cylinders 2 are connected to the axle 4 and the front axle 1 respectively. Rear axle 7 is rigidly connected with vehicle frame 4. The front axle 1 is connected with the vehicle frame 4 through a pin shaft 3 .

[0023] The role of the shuttle valve 6 in this specific embodiment: the axle balance system controls the oil power source. When the vehicle is running, port A (or port B) builds up pressure to drive the traveling motor, and the shuttle valve 6 can automatically compare the pressures of port A and port B, and select a higher pressure as the power source of the axle balance system.

[0024] Solenoid valve 5 of this specific embodiment: used to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com