Lifting hydraulic power catwalk system

A technology of hydraulic power and catwalk, applied in drilling equipment, earth-moving drilling, drill pipe, etc., can solve the problems of lack of automation, small type and quantity, limited adjustment range, etc., to improve operation safety, reduce procurement costs, The effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and example the present invention will be further described:

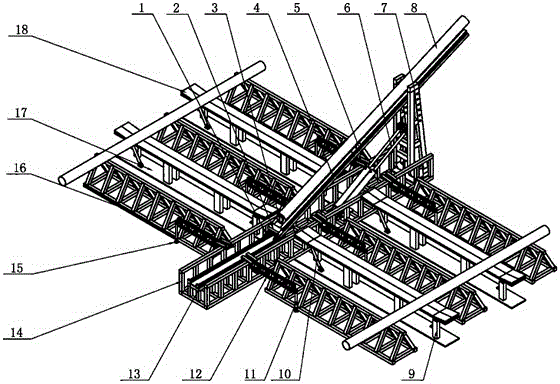

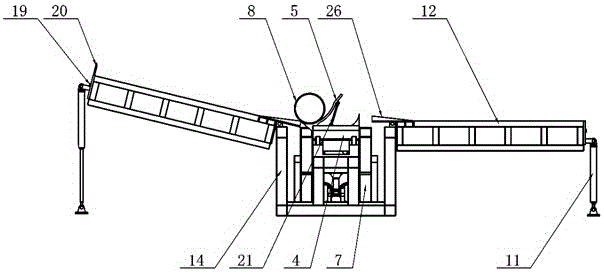

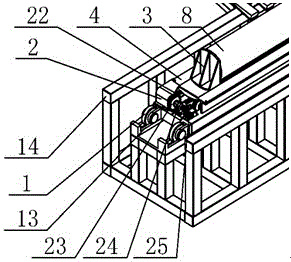

[0016] Such as figure 1 , figure 2 and image 3 As shown, the lift-type hydraulic power catwalk system of the present invention includes five mechanisms of a drilling tool rack turning out mechanism, a turning arm mechanism, a turning plate mechanism, a lifting mechanism, and a pulley mechanism.

[0017] The specific structure of the drill rack pull-out mechanism is that the pull-out hydraulic cylinder 10 is hinged with a fixed point on the bottom plate 17, the other end is hinged with one end of the pull-out plate 18, and the other end of the pull-out plate 18 is hinged with the support frame 9. The support frame 9 is fixed on the base plate 17 .

[0018] The specific structure of the turning arm mechanism is that the lifting plate 26 is fixed on one end of the turning arm 12, in order to prevent the drilling tool 8 coming from the drilling tool frame 16 fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com