Production method of hollow aluminum-plastic panel

A production method and technology for aluminum-plastic panels, which are applied in the fields of decoration and construction, can solve the problems that cannot be used to produce hollow aluminum-plastic panels, etc., and achieve the effects of not easy to deform, high adhesion, and stable mechanical structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

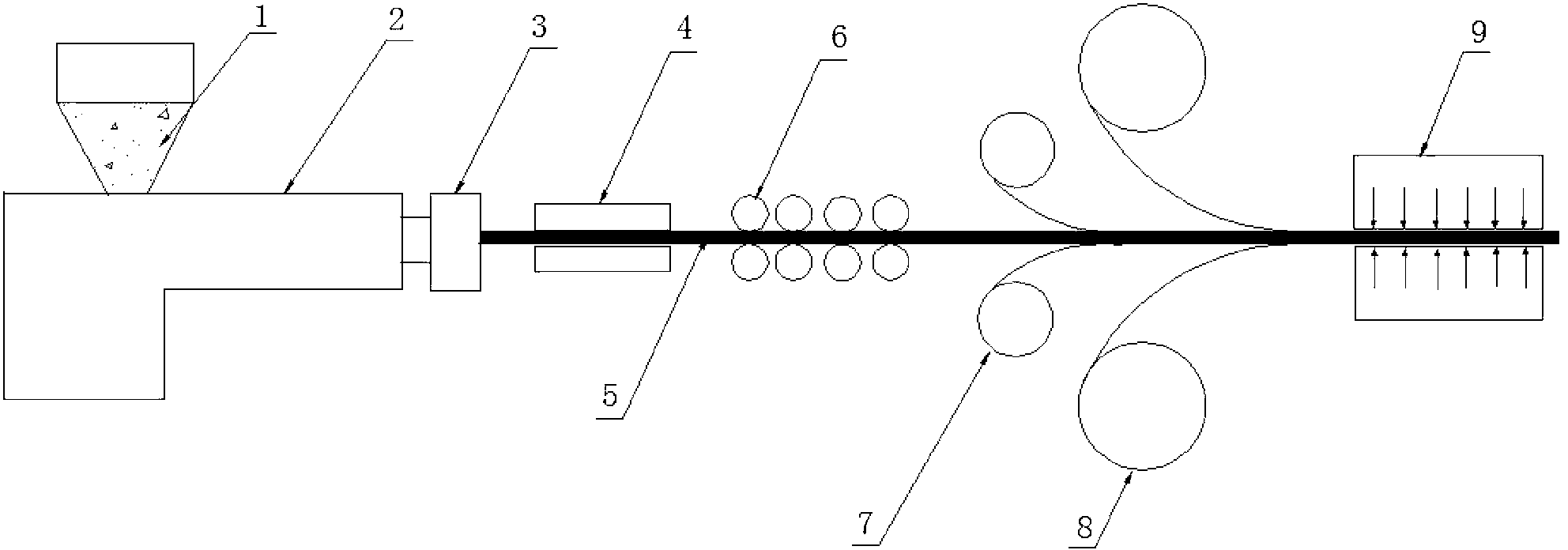

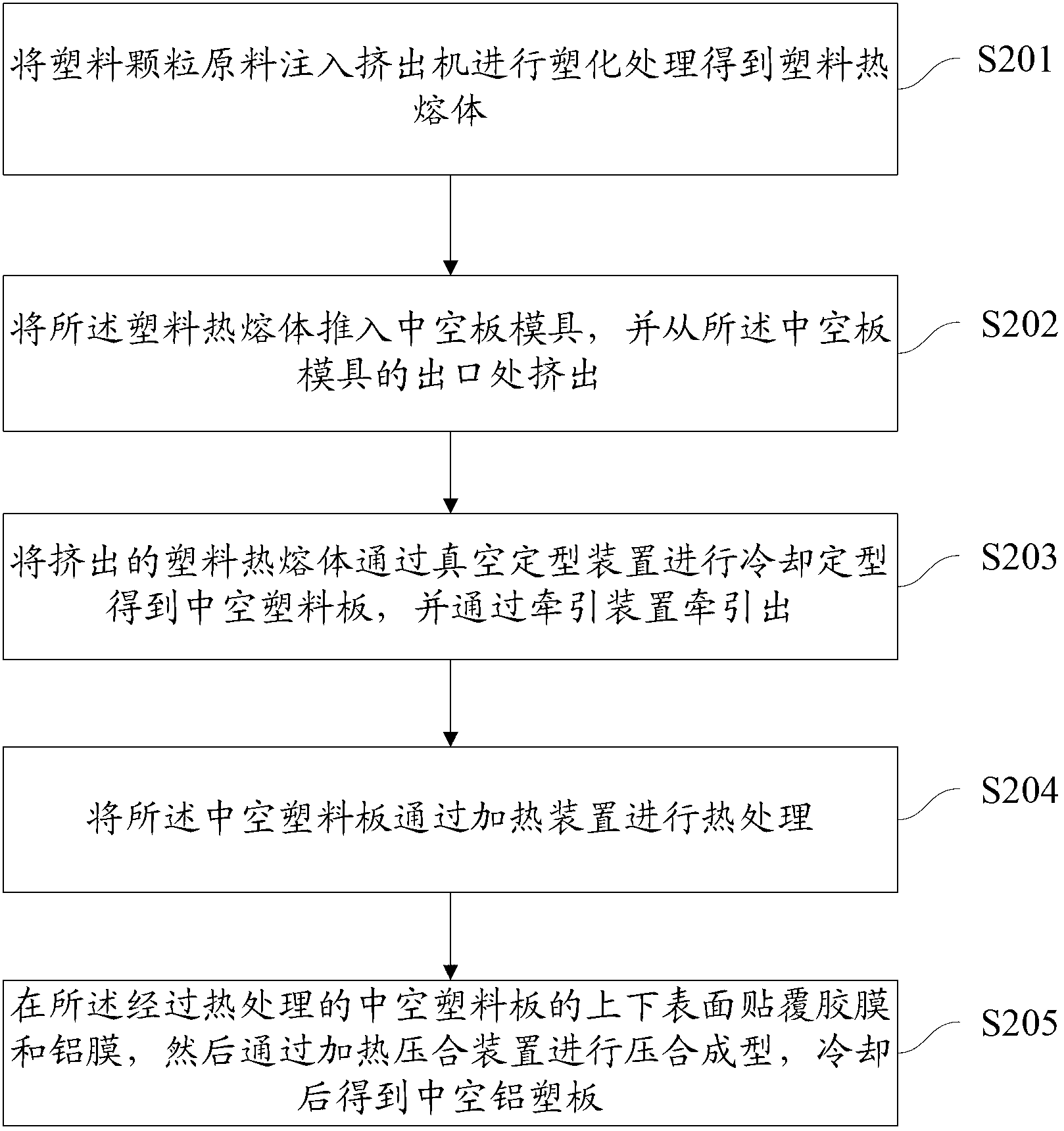

Method used

Image

Examples

Embodiment approach

[0034] As a preferred implementation manner, after the step S205, it also includes:

[0035] Step S206, sticking a protective film on the upper surface and / or lower surface of the hollow aluminum-plastic panel.

[0036] In order to protect the aluminum film on the surface of the hollow aluminum-plastic panel from abrasion, in this step, a protective film may also be pasted on the upper surface and / or lower surface of the hollow aluminum-plastic panel. After the user installs the hollow aluminum-plastic panel, tear off the protective film, which can ensure that the aluminum film of the hollow aluminum-plastic panel will not be worn during transportation or installation.

[0037] Further, as a preferred implementation manner, after the step S205, it also includes:

[0038] Step S207 , cutting the hollow aluminum-plastic panel according to actual needs to obtain a finished hollow aluminum-plastic panel.

[0039] The hollow aluminum-plastic panel produced on the production line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com