A method of pretensioning cables for superlifting all-terrain cranes

An all-terrain, crane technology, applied in cranes, load hanging components, transportation and packaging, etc., can solve problems such as increasing costs, and achieve the effects of saving manufacturing costs, saving preparation time, and reducing operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings of the examples of the present invention.

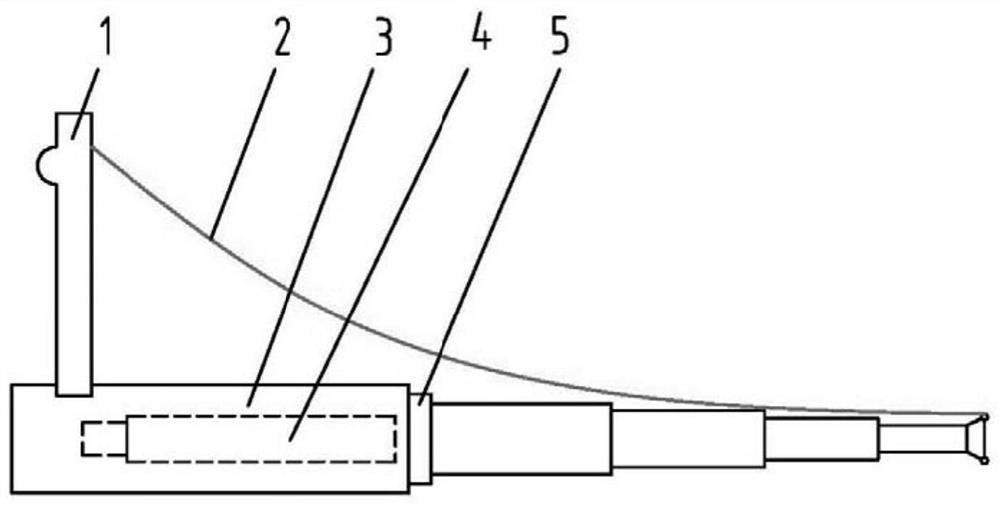

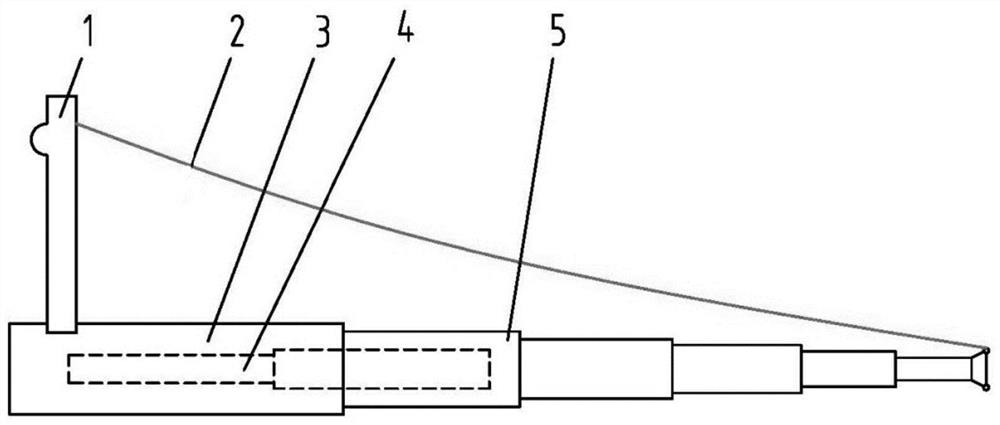

[0021] figure 1 Show the state when reaching the rope-laying position in the present embodiment, corresponding to the above-mentioned second step step, at this moment except the other arm sections of the second section arm 5 all stretch out. Such as figure 1 As shown, the hoist, hydraulic motor, locking device, etc. are located at the head of the super-lifting strut 1, which are not shown in the figure. The locking device is used to fix the length of the rope, including ratchet wheels installed on the two outer rims of the winch, a ratchet that can be controlled by a signal to open and close, and an encoder to detect the angle of rotation of the winch so as to obtain the length of the super-lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com