Negative pressure type compact spinning head-lapping method

A compact spinning, negative pressure technology, applied in spinning machines, piecing devices, textiles and papermaking, etc., can solve the problem of not finding the same or similar technical solutions, improve the efficiency of stitching, improve the quality of fabrics, The effect of reducing "slub" yarn defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

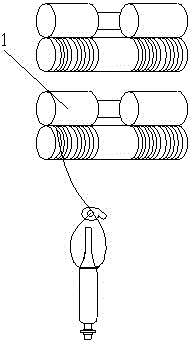

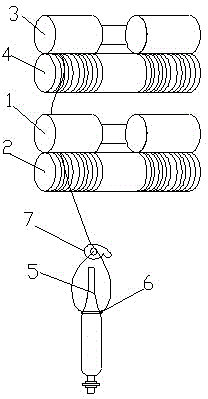

[0026] Such as figure 2 Shown, the present invention discloses a kind of negative pressure type compact spinning head lapping method, and this method is to adopt double top roller lapping method on the spinning machine that negative pressure type compact spinning is installed, promptly front top roller 3 and front roller 4. The jaws of the composition take up the spinning.

[0027] The specific steps of the above-mentioned double top roller lapping method are as follows:

[0028] (1) Extubation: use the middle finger of the left hand as the main finger, and the ring and little fingers as the auxiliary to hold the bobbin 5 and pull it out. The extubation should be light and fast;

[0029] (2) Finding the end: use the thumb and index finger of the right hand to pinch the end of the yarn to lead out the yarn, and find the position of the end of the yarn quickly;

[0030] (3) Yarn drawing: lead the yarn out from the bobbin, then take out the traveler 6 with the index finger of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com