Liquid viscoelastic damper

A viscoelastic and damper technology, applied in the field of structural protection, can solve the problems of limited energy dissipation capacity, poor durability and stability, load frequency, and small output, and achieve the effects of avoiding repeated vibration, easy use, and suppressing excessive displacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

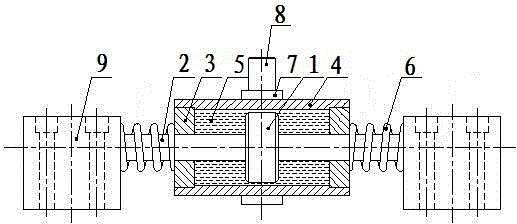

[0013] Embodiment 1 of the present invention: The structure diagram of a liquid viscoelastic damper of the present invention is as figure 1 As shown, the liquid viscoelastic damper includes a damping mechanism composed of a commercially available piston 1, a piston rod 2, an end cover 3, a cylinder 4, and a liquid damping medium 5. The elastic element 6 can be sleeved on both ends of the piston rod 2 to form an elastic mechanism to provide rigid support for the movement of the piston rod 2. Among them, the elastic element 6 can be a cylindrical helical compression spring, a disc spring, or a combination of various existing commercially available springs. The collar 7 can be connected to the cylinder 4, the pin 8 is connected to the collar 7, and then two fixed blocks 9 are respectively installed on the outer sides of the two ends of the piston rod 2 to form a connecting mechanism. Connect one end of the elastic element 6 to the end cap 3, connect the other end of the elastic e...

Embodiment 2

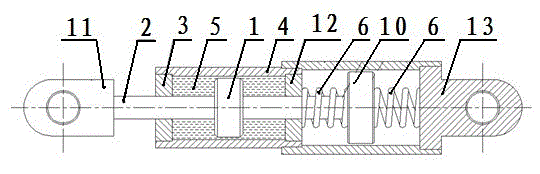

[0015] Embodiment 2 of the present invention: The structure diagram of another liquid viscoelastic damper of the present invention is as follows figure 2 As shown, the liquid viscoelastic damper includes a damping mechanism composed of a commercially available piston 1, a piston rod 2, an end cover 3, a cylinder 4, and a liquid damping medium 5. Two elastic elements 6 can be installed, and the elastic piston 10 is connected to one end of the piston rod 2 to form an elastic mechanism, which provides rigid support for the movement of the piston rod 2. Among them, the elastic element 6 can be a cylindrical helical compression spring, a disc spring, or a combination of various existing commercially available springs. The earring 11 is connected to the other end of the piston rod 2, the outer cylinder 12 is placed outside the elastic mechanism and its inner diameter is made larger than the cylinder 4, and the connecting earring 13 is connected to the outer cylinder 12 to form a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com