Rubber blanking cap of guided missile engine exhaust nozzle

A tail nozzle and rubber plugging technology, which is applied in the direction of machines/engines, rocket engine devices, jet propulsion devices, etc., can solve problems such as low reliability, difficult process control, complex structure, etc., to ensure the safety of ground equipment and simplify the design The effect of convenient structure and process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Referring to the drawings showing embodiments of the present invention, the present invention will be described in more detail below. However, the present invention can be implemented in many different forms and should not be construed as being limited by the embodiments presented herein. On the contrary, these embodiments are proposed to achieve a full and complete disclosure, and to enable those skilled in the art to fully understand the scope of the present invention.

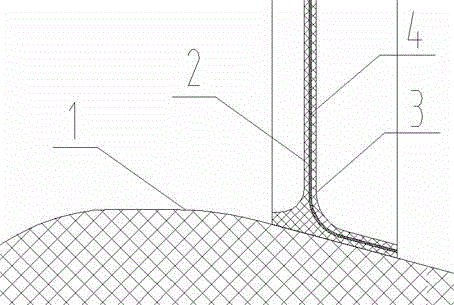

[0019] Such as figure 1 Shown is a schematic diagram of the structure of the rubber plug of the tail nozzle of the missile launcher of the present invention.

[0020] The throat lining 1 is made of felt carbon / carbon composite material. The throat lining 1 and the front and rear rubber layer assemblies are bonded at the expansion section of the throat lining 1 through 730 glue, and the thickness of the glue layer is not more than 0.1; the assembly is made of The front rubber layer 2 and the rear rubber l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com