Double-layer thermal insulated composite sealing device for feed opening

A composite sealing and double-layer sealing technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of inability to truly seal, unstable atmosphere in the furnace, and easy decarburization of products, so as to reduce product decarburization Carbon and blackening, reducing the leakage of furnace atmosphere, reducing the cost of replacement and the effect of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

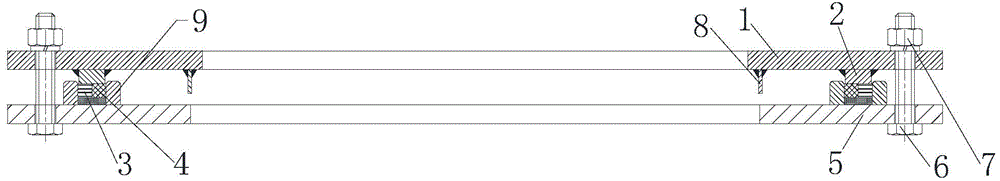

[0011] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 , 2 As shown, the present invention includes an upper flange 1 and a lower flange 5. The upper flange 1 is welded with a bead 2, and the lower flange 5 corresponding to the bead 2 is welded with a fixing bar 9. A double-layer sealing strip is placed in the strip 9; the bead 2 on the upper flange 1 is tightly pressed against the double-layer sealing strip in the fixing strip 9 during the assembly process, and is fixed by high-strength bolts 6 and nuts 7; The first-layer sealing strip is composed of polytetrafluoroethylene tape 3 and high-temperature oil-infiltrated asbestos packing 4, the high-temperature oil-infiltrated asbestos packing 4 is installed on the inside, and the Teflon tape 3 is installed on the outside, that is, the high-temperature oil-infiltrated asbestos packing 4 is located on the The inner side of the polytetrafluoroethylene belt 3; the inner sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com