Supersolid visual resolution element

A vision separation, super three-dimensional technology, applied in the field of 3D image display, can solve the problems of lack of consistency in production, inability to meet high-precision, high-efficiency and low-cost mass production, and achieve the effect of low-cost mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

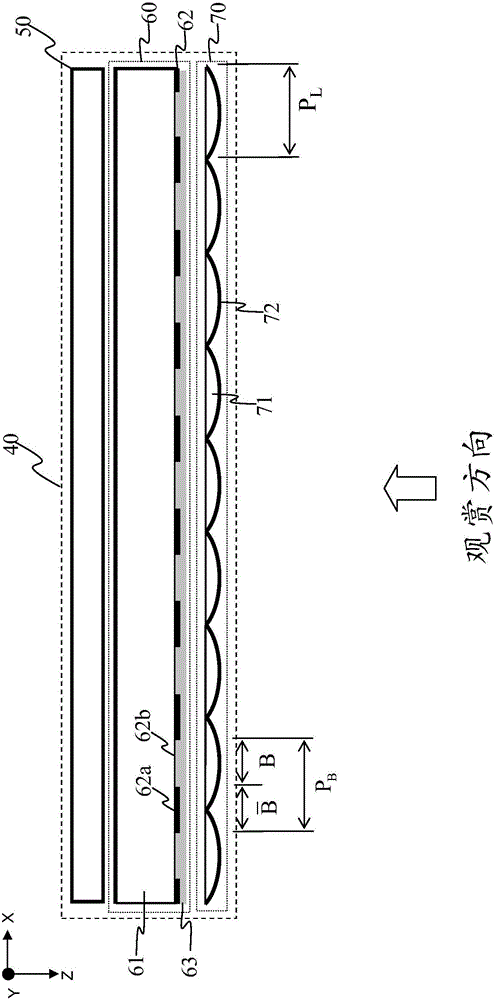

[0070] Such as Figure 6 Shown is a schematic structural view of the super stereoscopic view separation element of the present invention. The super stereoscopic separation element 1 is composed of a lens element 10 , a parallax barrier element 20 and a flexible transparent base material 30 sequentially from top to bottom.

[0071] Wherein, the lens element 10 is composed of a plurality of cylindrical lenses 11 arranged in vertical strips, wherein the single cylindrical lens 11 has a lens surface 12, a focal length fL (no icon), an optical refractive index nL and One cell structure width PL. The lens surface 12 can be formed by a circular curved surface or a non-circular symmetrical curved surface.

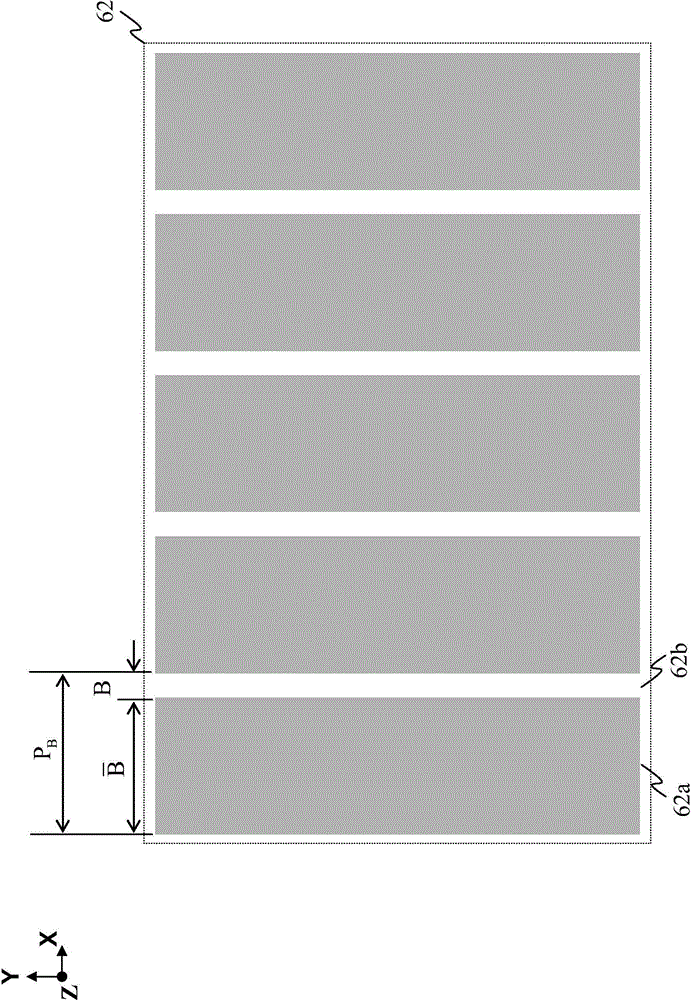

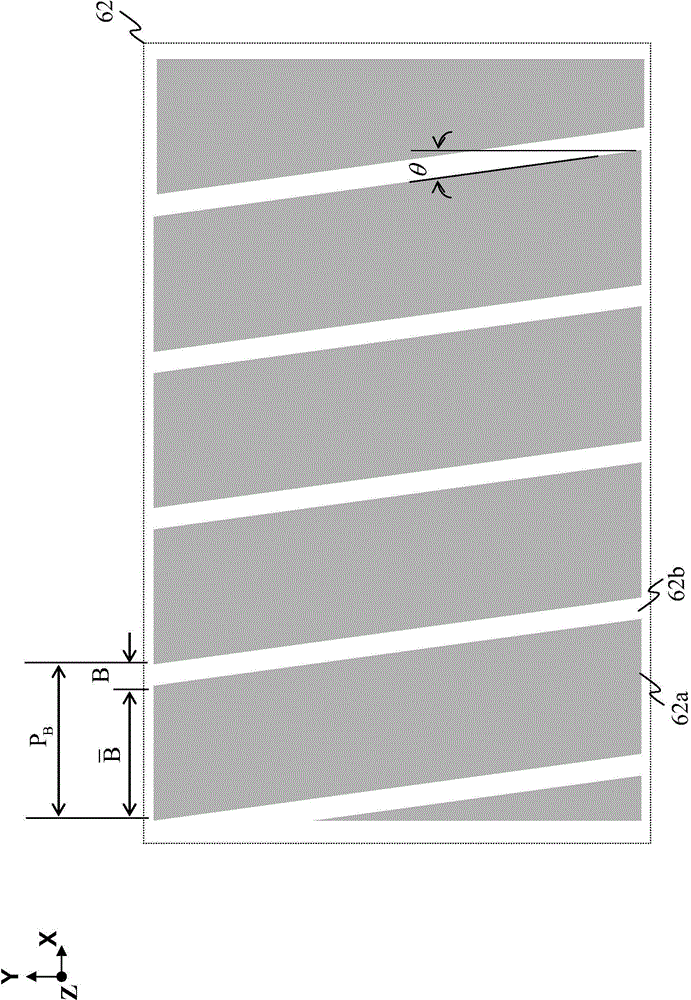

[0072] The parallax barrier element 20 is composed of a plurality of light-shielding elements 21 and a plurality of light-transmitting elements 22 . The single light-shielding element 21 and the single light-transmitting element 22 have the characteristics of a vertical strip st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com