A Nonlinear Predictive Control Method of lpv Model Based on Interior Point Method

A technology of nonlinear prediction and control methods, which is applied in the direction of adaptive control, general control system, control/regulation system, etc., and can solve problems such as QP problem solving becomes a bottleneck, large amount of online calculation, and low solution accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

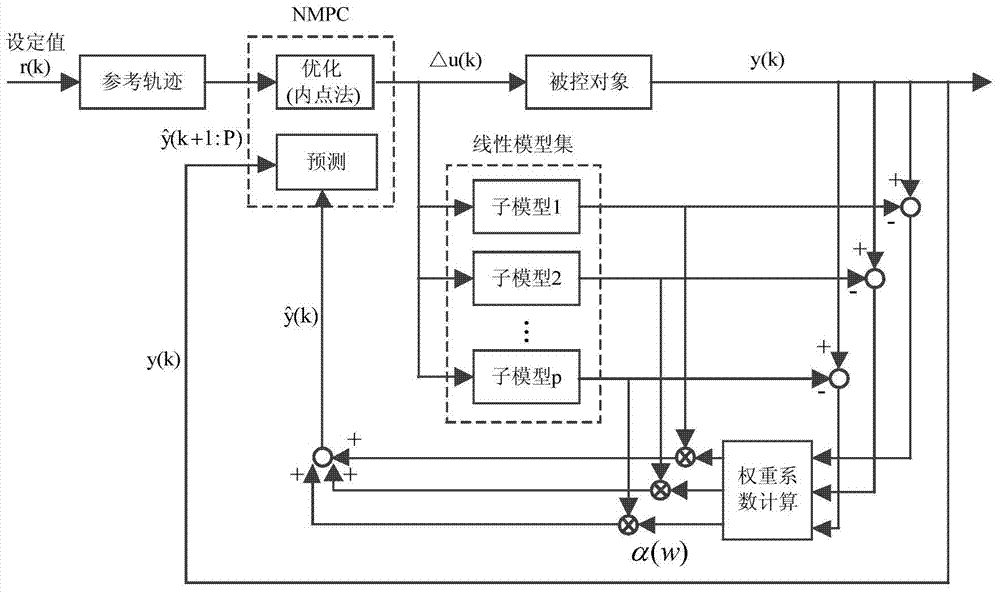

[0059] like figure 1 Shown is the block diagram of the control system of the present invention, wherein the sub-model i, (i=1, 2, . . . p ) is a linear model set obtained after selecting working points in the operating space of the system. Since the working point variable is one of the input variables, at the sampling time k, the weight coefficient α(w) of each linear sub-model is calculated by using the weight function formula according to the distance between the actual output of the controlled object and each working point; according to the global The LPV model obtains the predicted output from time k+1 to P; at time k, use the interior point method to solve an optimization proposition on a finite time domain [k, k+P], and solve the current control increment Δu(k) act on the system. At the next sampling time, the nonlinear predic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com