An effective control method for CO2 capture system operation after photothermal assisted combustion

A technology of auxiliary combustion and operation control, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of slow characteristics of the capture system and difficulty of operation control, so as to enhance the adaptability and improve the quality of operation adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

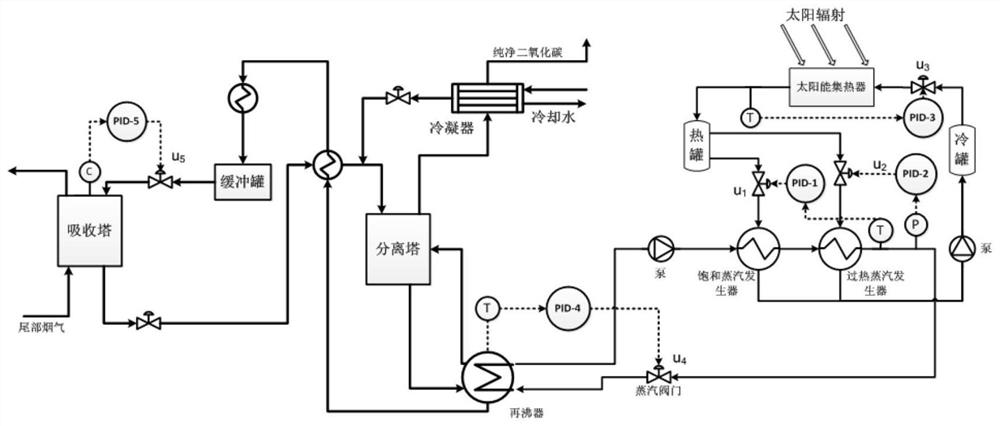

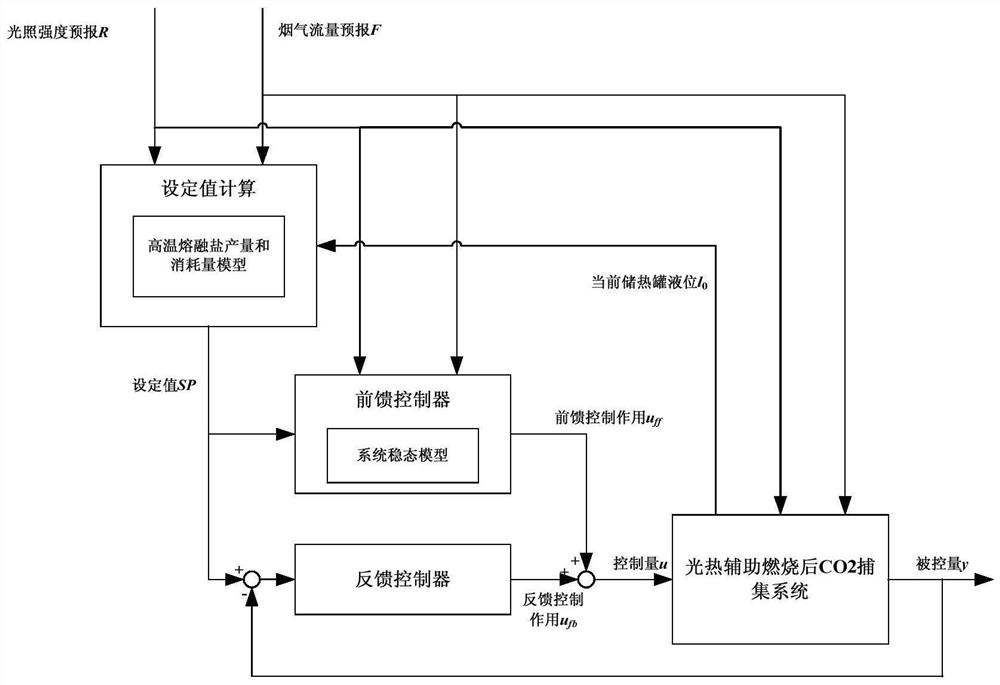

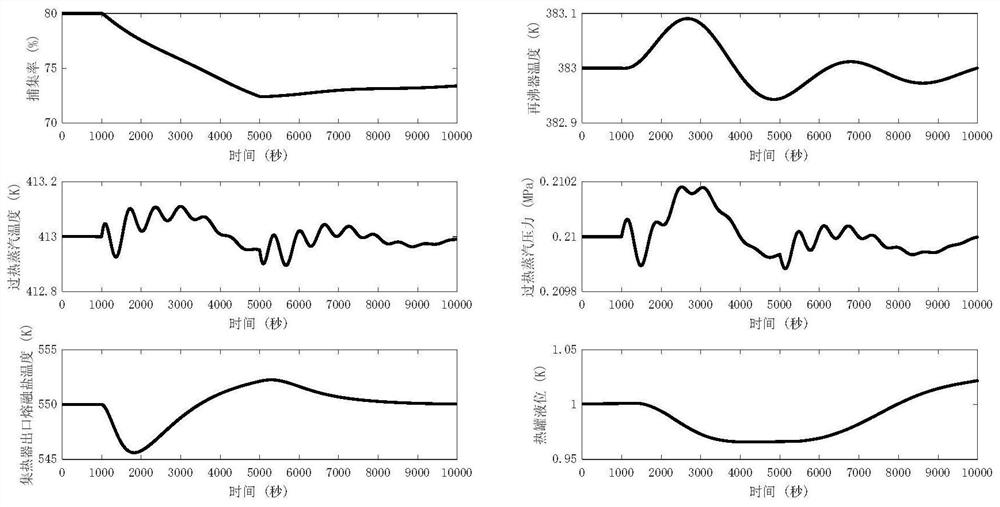

[0025] Such as figure 1 As shown, the control method uses a trough photothermal assisted chemical adsorption with molten salt energy storage for CO after combustion 2 The capture system is the controlled object, select CO 2 Collection rate, reboiler temperature, superheated steam pressure, temperature, and molten salt temperature at the outlet of the trough solar collector are the system controlled quantities; select lean liquid flow, steam valve opening, saturated steam generator molten salt flow, superheat The molten salt flow rate of the collector and the molten salt flow rate of the collector are the system control quantities. First, based on the steady-state system model, considering the flue gas flow of thermal power plants, system energy storage, and illumination, determine the appropriate CO for system operation 2 The capture rate setting value and the feedforward control amount are combined with the feedback control system based on the PI loop to establish a phototherma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com