Self-adhesive flexible capacitive touch screen

A technology of capacitive touch and flexible capacitors, which is applied in the fields of electrical digital data processing, instruments, calculations, etc., can solve the problems of inseparable maintenance of fully bonded integrated screens, high repair costs of fully bonded screens, and difficult removal of air bubbles, etc. , achieve the effects of simple structure, improved anti-interference, and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

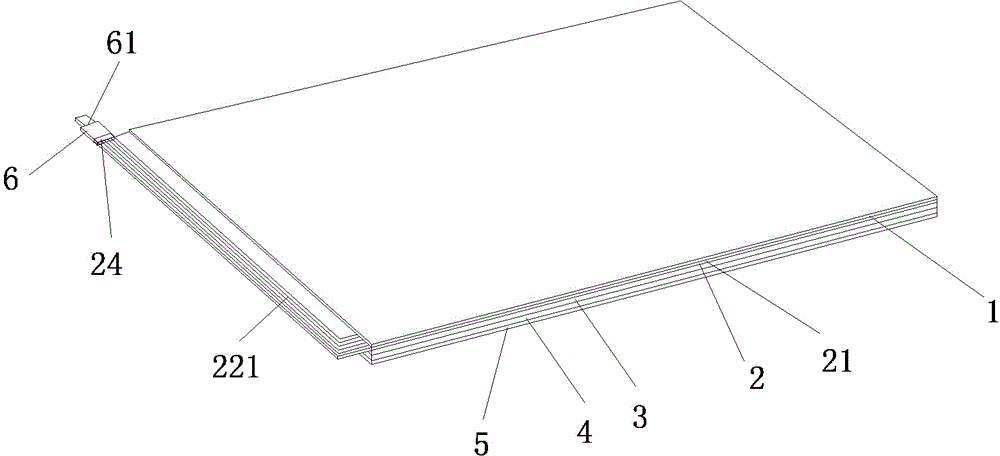

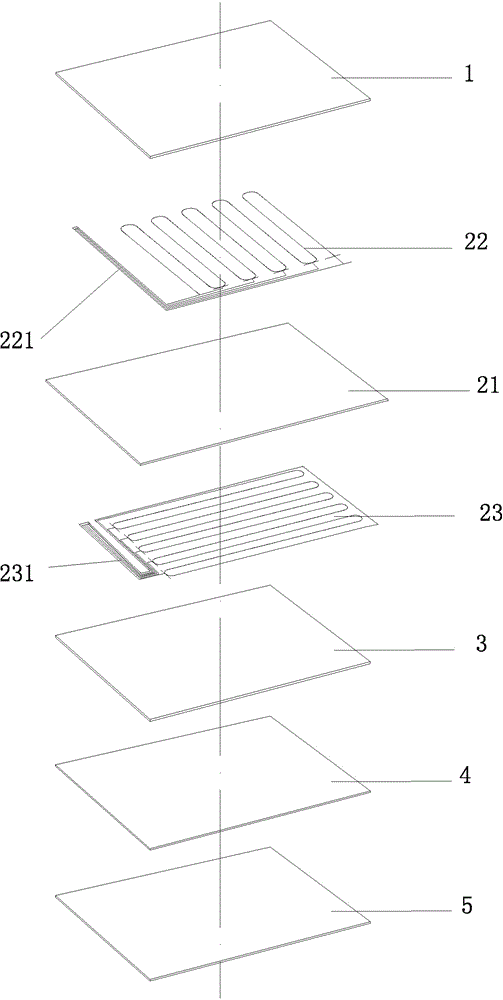

[0017] Such as figure 1 with figure 2 As shown, a self-adhesive flexible capacitive touch screen, which includes a flexible tempered glass 1, a capacitive touch sensing film 2 and a transparent flexible film 3 bonded sequentially by an adhesive, the bottom surface of the transparent flexible film Pasted with silica gel 4, the bottom surface of the silica gel 4 is attached with a release film 5. The capacitive touch film sensor 2 includes a transparent plastic film 21, and the front and back of the transparent plastic film 21 have horizontal conductive lines 22 and vertical conductive lines respectively The wire 23 , the horizontal conductive wire 22 and the lead wire 221 , 231 of the vertical conductive wire 23 are provided with gold fingers 24 for connecting with the IC controller 6 , and the IC controller 6 is provided with a USB output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com