Multiple spark route for lightning protection

A spark gap and multiple technology, applied in the direction of spark gap, overvoltage arrester using spark gap, electrical components, etc., can solve the problems of assembly cost and limitation, and achieve simplified operation, reduced assembly cost, and reduced space requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

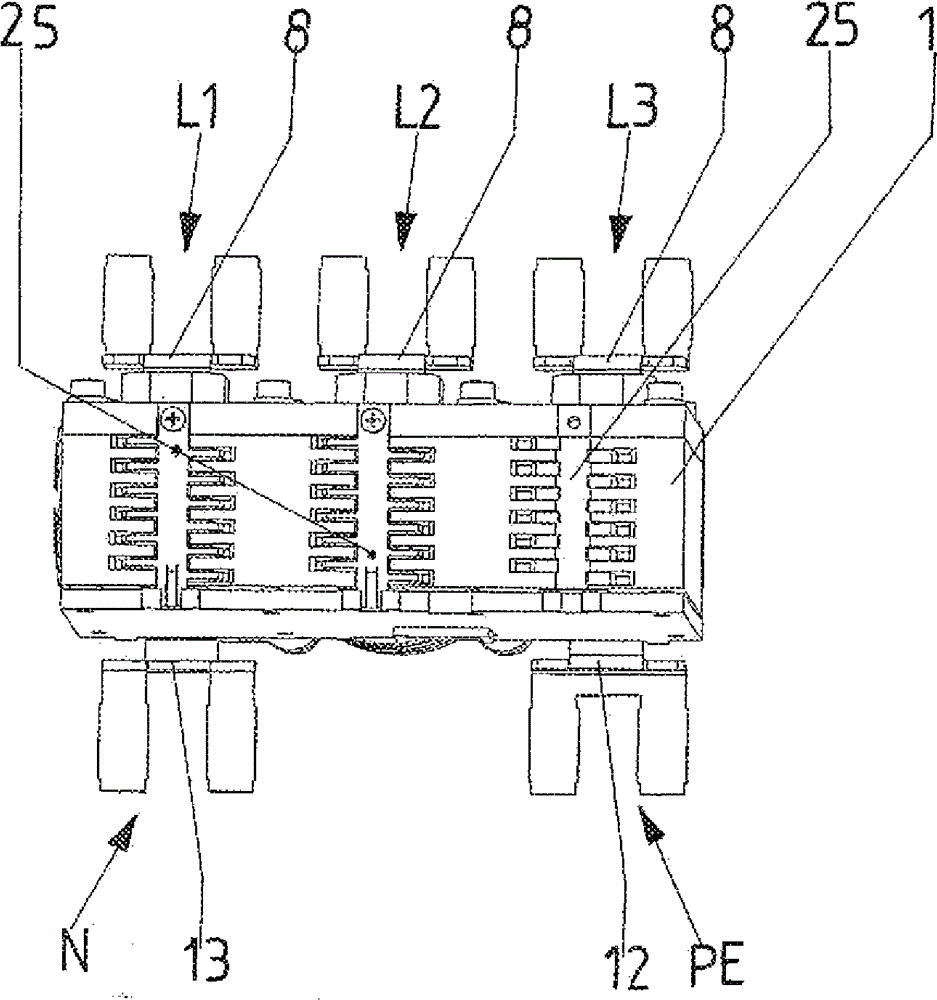

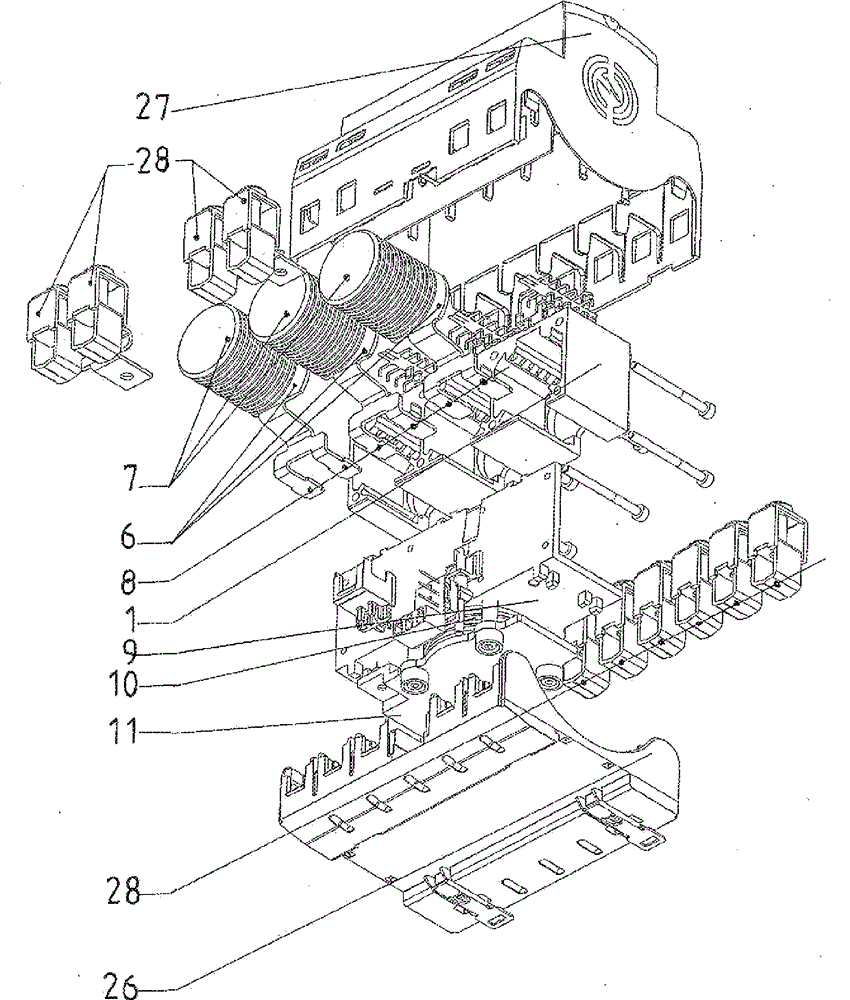

[0085] In the exemplary embodiment, a multipolar multiple spark gap for lightning protection is shown, which is combined in a single device. The important components of the design scheme are the following.

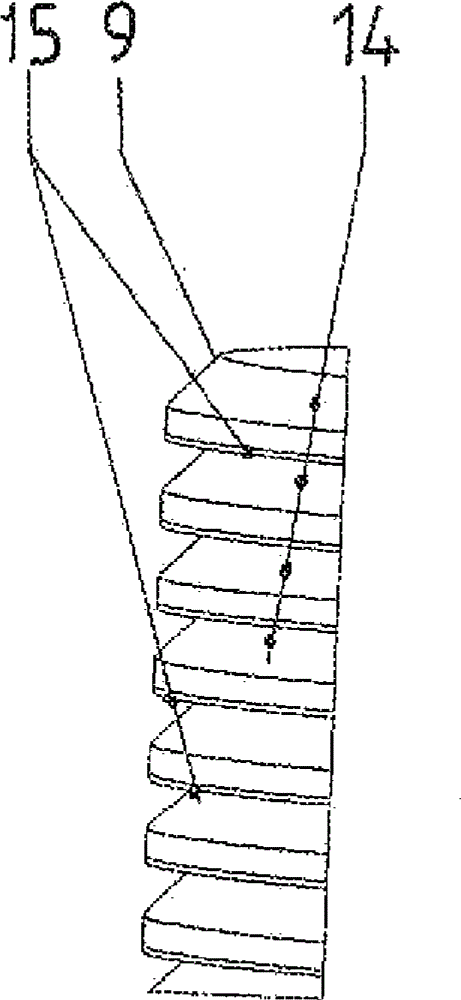

[0086] A housing 1 of insulating material, for example made of plastic, is provided which has a plurality of chambers 2 , 3 , 4 which are isolated from one another. especially by Image 6 It can be seen that the chambers 2 , 3 , 4 are designed in such a way that they exit openly towards the housing side. A coupling contact plate 6 is inserted into these cavities 2, 3, 4 adjacent to the housing bottom 5, respectively, on which is stacked a spark gap 7 in contact with it, which spark gap 7 is inserted into the corresponding cavity 2, 3, 4 . Each connecting contact plate 6 has a respective connecting piece 8 for an electrical conductor on a bent arm, wherein the connecting piece 8 is led out through the housing wall of the insulating material housing 1 towards its outer si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com