Prefabricated power transformation box with automatic opening and shutting door

An automatic door opening and closing, pre-installed technology, applied in the cooling/ventilation of substation/switchgear, substation/switch layout details, electrical components, etc. , to ensure normal and safe operation, reduce production cycle and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described in detail below in conjunction with specific drawings. It should be noted that the technical features or combinations of technical features described in the following embodiments should not be regarded as isolated, and they can be combined with each other to achieve better technical effects. In the drawings of the following embodiments, the same reference numerals appearing in each drawing represent the same features or components, which can be applied in different embodiments.

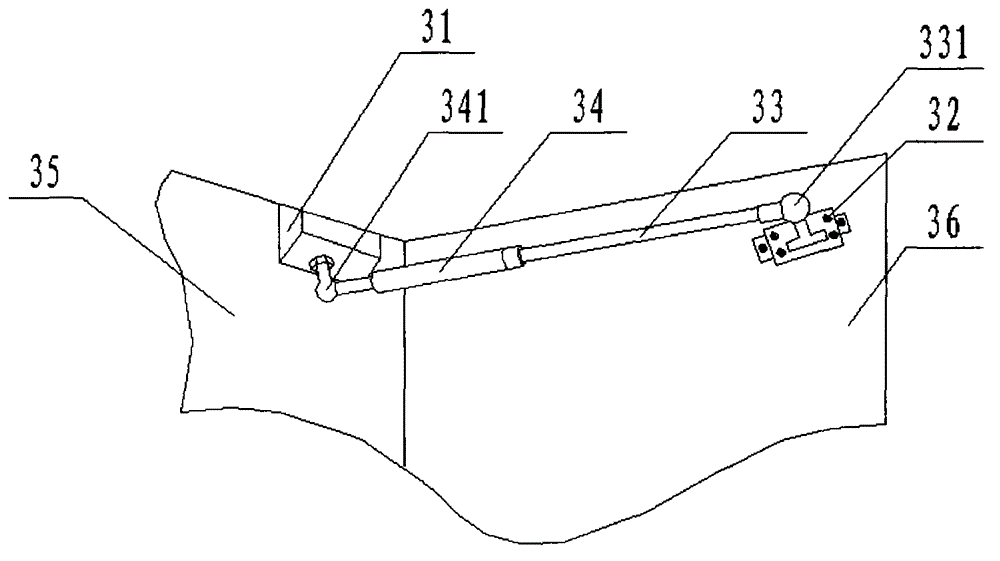

[0028] figure 1 Shown is a schematic diagram of an automatic opening and closing door of a prefabricated transformer box provided with an automatic opening and closing door according to the present invention.

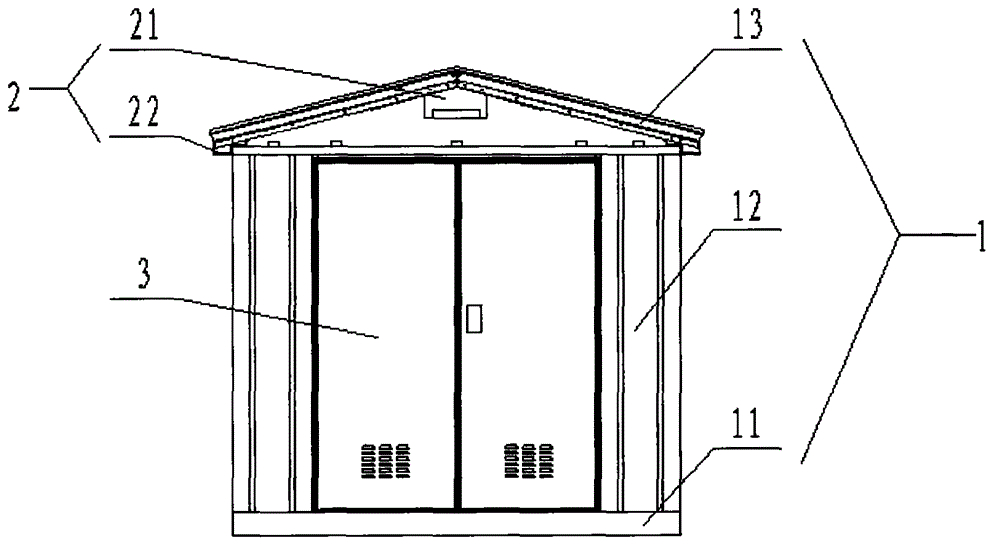

[0029] figure 2 Shown is a front view of a prefabricated transformer box provided with an automatic opening and closing door of the present invention.

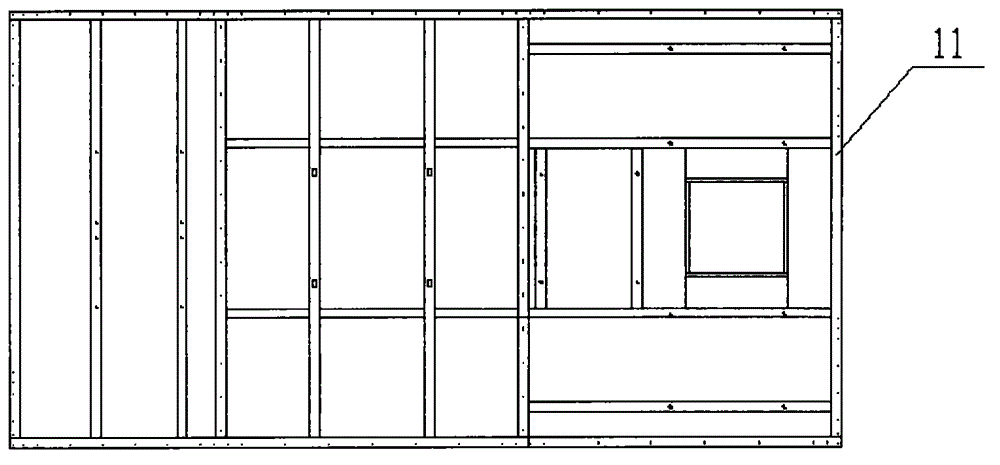

[0030] image 3 Shown is a bottom schematic diagram of a prefabric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com