Fabricated building phase change thermal insulation wall

A thermal insulation wall and prefabricated technology, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems of lack of temperature adjustment and thermal insulation effects, inability to change heat transfer efficiency, and inability to change energy storage effects, etc., to achieve enhanced Heat transfer efficiency, prevent heat from being lost to the outside, and avoid the effect of external heat interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

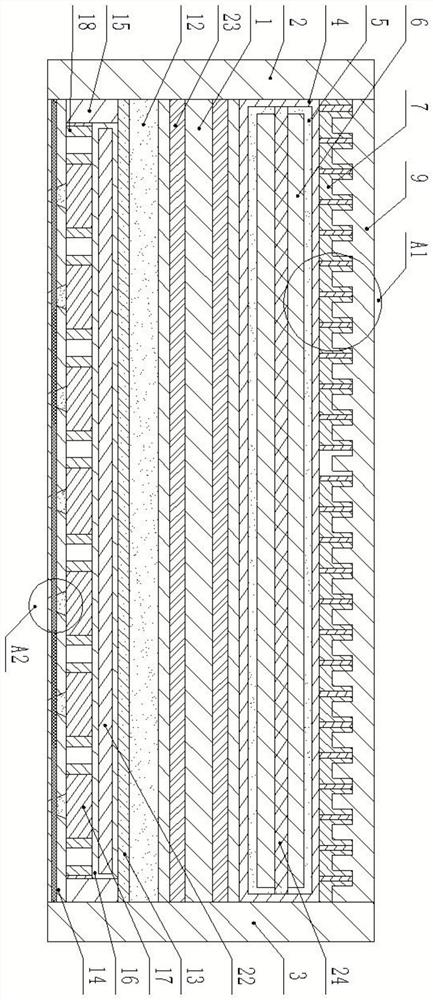

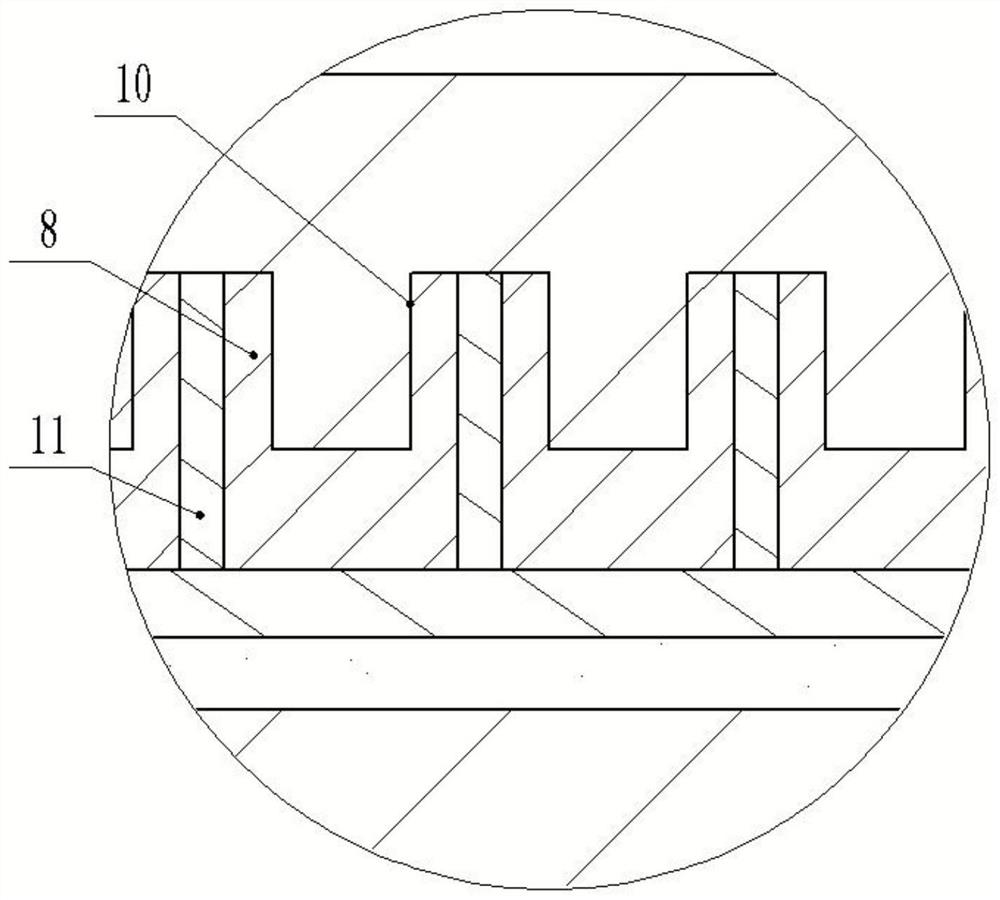

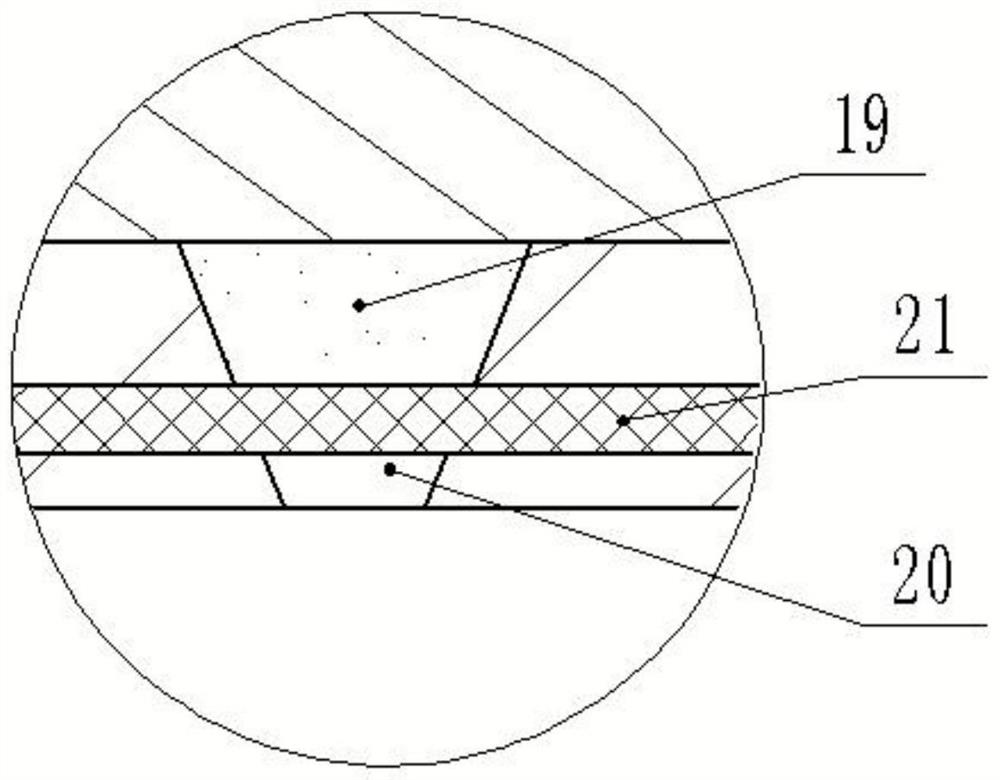

[0032] refer to Figure 1-3 , the present invention provides, a phase-change thermal insulation wall of a prefabricated building, comprising: a support plate 1, one end of the support plate 1 is fixedly connected with a receiving plate 2, the other end of the supporting plate 1 is fixedly connected with a plug-in plate 3, and the receiving plate 2 and the socket plate 3 are arranged symmetrically with respect to the support plate 1, the top surface of the support plate 1 is fixed with a positioning housing 4, and the two ends of the positioning shell 4 are respectively fixed with the sides of the receiving plate 2 and the socket plate 3, and the positioning shell 4 is provided with a rubber layer 5, and the rubber layer 5 is provided with a phase change layer 6. The top surface of the positioning housing 4 is fixed with a heat conduction plate 7, and the top surface of the heat conduction plate 7 is fixed with a number of bar-shaped bumps 8 at equal intervals to conduct heat. ...

Embodiment 2

[0050] refer to Figure 4-5 , in the present embodiment, an air guide device is provided outside the outer wall panel 14, the air guide device provided includes an air guide frame 25, the top surface of the air guide frame 25 is fixedly connected with the bottom surface of the receiving plate 2 and the plug-in plate 3, and the air guide Several blades 26 are arranged in the frame 25, and the two ends of the blades 26 are respectively connected with two opposite inner walls of the air guide frame 25, and the blades 26 on both sides in the air guide frame 25 are inclined in opposite directions. The wind from the wind direction can flow into the heat insulation mechanism, so that the wind enters from one side and flows out from the other side, taking away the heat, realizing the circulation of gas and improving the heat dissipation effect. At the same time, the setting similar to the louvers can enhance the aesthetics. The inclination angle of the blade 26 can also be manually ad...

Embodiment 3

[0052] refer to Figure 6-10 , the present embodiment provides a connection device, the connection device includes a plug-in pipe 30, a grouting hole 27 is opened in the support plate 1, and the two ends of the grouting hole 27 respectively pass through the receiving plate 2 and the plug-in board 3, and the side of the plug-in board 3 A socket block 28 is fixedly connected, and the side of the receiving plate 2 is provided with a socket slot 29 that is compatible with the socket block 28, and one end of the grouting hole 27 on the socket plate 3 is connected to a socket pipe 30, and the socket pipe 30 is connected to the receiving plate 3. The grouting holes 27 on the plate 2 are matched with each other, and the pipe wall at the top of the plug-in pipe 30 is provided with a gap 31 . After connecting multiple phase-change walls, grout into the grouting holes 27 on the most side. When the cement in the multiple grouting holes 27 is fully filled, the corresponding cement will flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com