Fertilizer fermentation tank

A fermentation tank and fertilizer technology, applied in the direction of organic fertilizer, organic fertilizer equipment, organic fertilizer preparation, etc., can solve the problems of affecting the working environment of the staff, reducing the effect of fermentation, and difficult to clean the fertilizer, so as to avoid difficult replacement and speed up Speed, improve the effect of sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

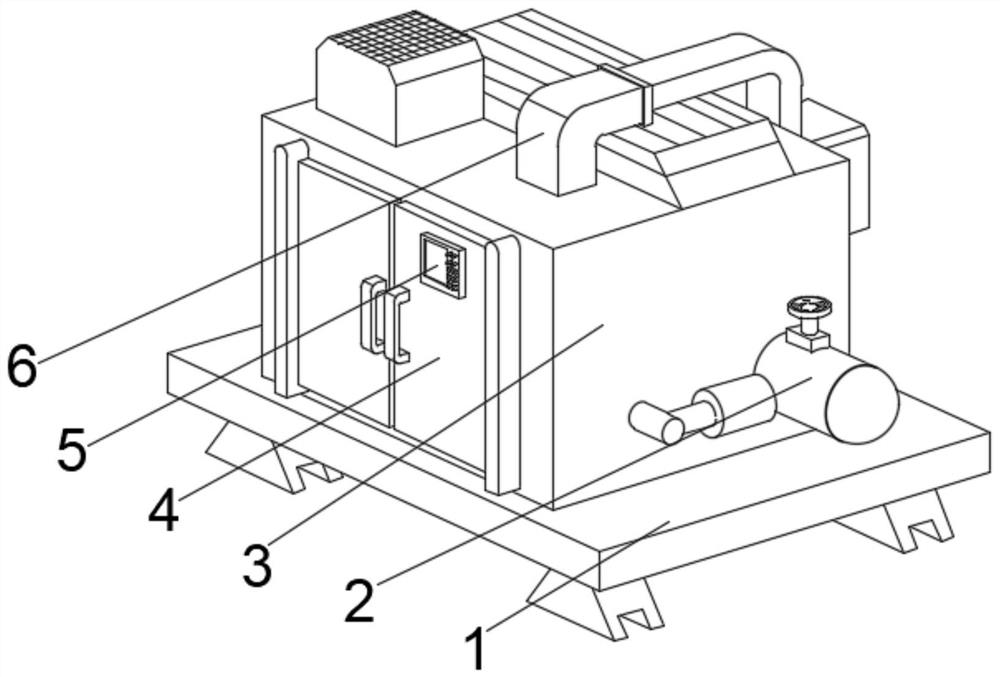

[0040] see Figure 1-2 , the present invention provides a technical solution: a fertilizer fermenter, comprising a mobile base 1, a fermentation device 3 is fixedly connected to the middle of the top of the mobile base 1, and an oxygen pump 2 is arranged at the bottom of the right outer wall of the fermentation device 3, and the oxygen pump The output end of 2 runs through the fermentation device 3 and extends to the inside of the fermentation device 3. A sealed box door 4 is arranged on the top of both sides of the front of the fermentation device 3, and a control panel 5 is fixedly connected to the right side of the top of the sealed box door 4. The fermentation device 3 The top right side of the top is communicated with heating pipe 6.

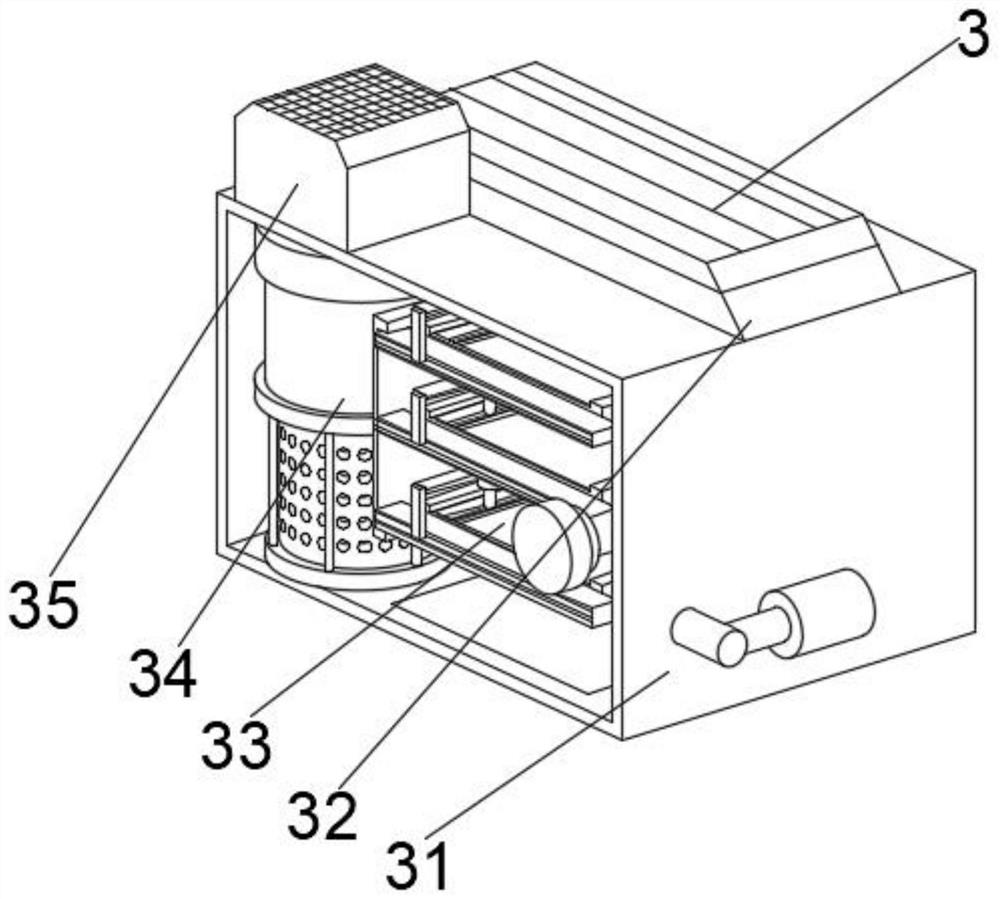

[0041] Wherein, the fermentation device 3 comprises a fermentation box 31, the top of the fermentation box 31 is fixedly connected with a fixed clamping plate 32 at the middle position on both sides of the top, the left side of the top of t...

Embodiment 2

[0047] see Figure 1-6 , on the basis of Embodiment 1, the present invention provides a technical solution: a method for using a fertilizer fermentation tank, step 1: move and install the device, and put the fertilizer through the sealed box door 4, after closing, open the oxygen The pump 2 supplies the interior, and energizes the heating pipe to heat, so that the heat flows into the fermentation device 3;

[0048] Step 2: the auxiliary mechanism 34 is connected with the regulating mechanism 33, and the gas passing through the auxiliary mechanism 34 is discharged through the gas-permeable box 35, and the fixed clamping plate 32 fixes the contacted objects, thereby realizing the circulation flow of the internal gas or temperature;

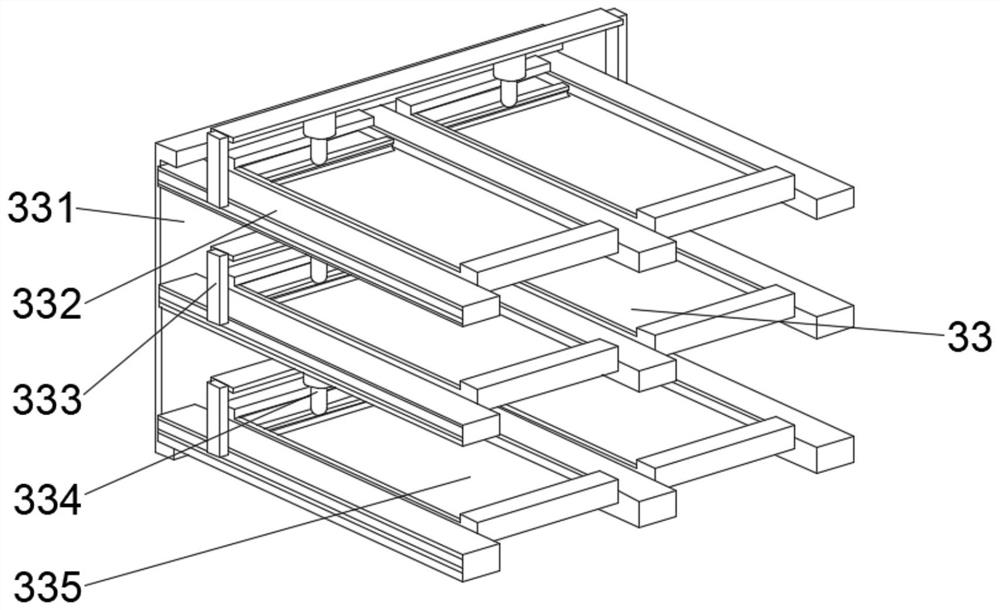

[0049] Step 3: When the fertilizer is put into the device, there is a space for the moving frame 333 to move between the plurality of fermentation bodies 335, and the fertilizer stored in the fermentation body 335 can be stored by the flipper 334 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com