Baked food cooling device capable of recycling waste heat for food processing

A food processing and waste heat recovery technology, which is applied in food processing, baked food processing, household refrigeration equipment, etc., can solve the problems of threatening consumers' health, easy to be polluted by bacteria or human beings, and long cooling time, so as to shorten the cooling time time, avoid direct contact with air, and improve the effect of reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

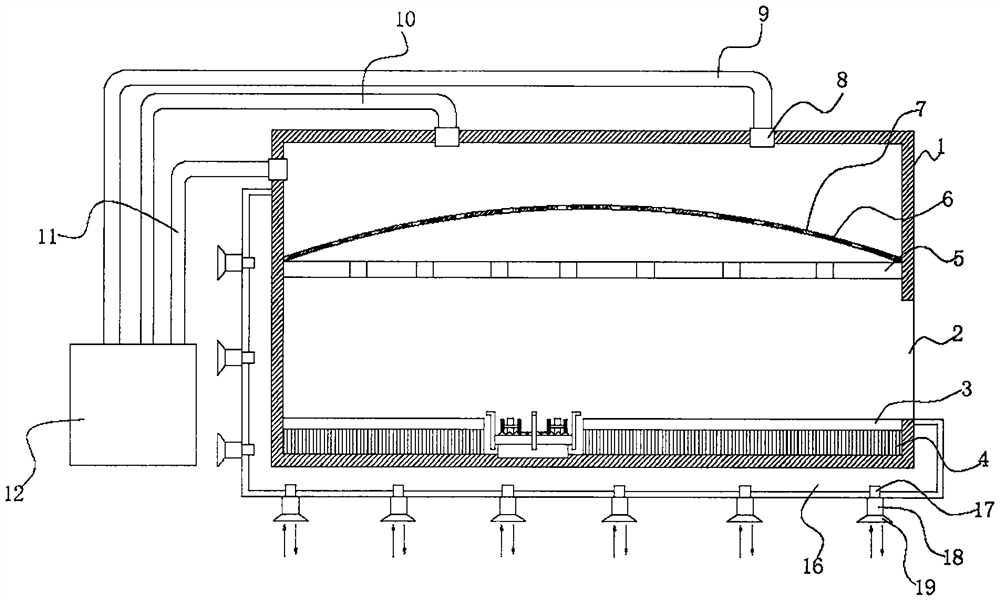

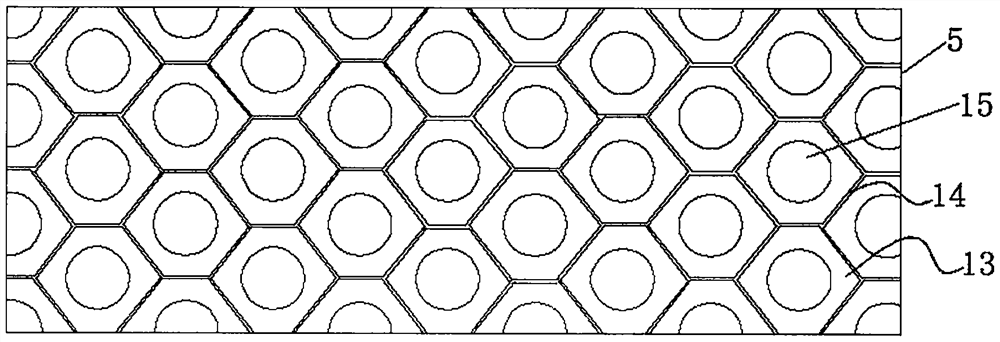

[0032] Such as Figure 1-2 displayed in:

[0033]The present invention provides a baked food cooling device for food processing that can recover waste heat, comprising a cooling box 1, an inlet 2 is provided at the bottom of one side of the cooling box 1, and the lower side of the cooling box 1 is located at the inlet 2 The bottom surface is provided with a bamboo mat bottom plate 3, a bottom cavity 4 is provided between the bottom of the bamboo mat bottom plate 3 and the inner bottom of the cooling box 1, and a Rotary mechanism, the top surface of the rotary mechanism is higher than the top surface of the bamboo mat bottom plate 3, wherein, the upper part of the cooling box 1 is provided with a honeycomb panel 5 across, and the top resin convex mirror 6 of the honeycomb panel 5 , the resin convex mirror 6 is provided with several exhaust holes 7, the top of the cooling box 1 and the top of the side away from the inlet 2 are provided with several air outlet ports 8, and the a...

Embodiment 2

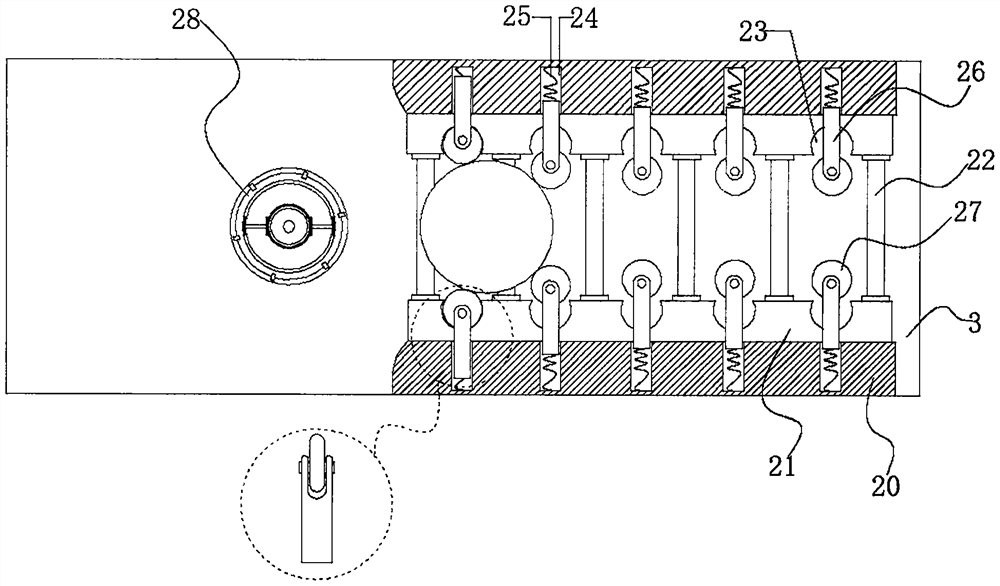

[0036] Such as figure 1 and Figure 3-4 displayed in:

[0037] The present invention provides a baked food cooling device for food processing that can recover waste heat, comprising a cooling box 1, an inlet 2 is provided at the bottom of one side of the cooling box 1, and the lower side of the cooling box 1 is located at the inlet 2 The bottom surface is provided with a bamboo mat bottom plate 3, a bottom cavity 4 is provided between the bottom of the bamboo mat bottom plate 3 and the inner bottom of the cooling box 1, and a Rotary mechanism, the top surface of the rotary mechanism is higher than the top surface of the bamboo mat bottom plate 3, wherein, the upper part of the cooling box 1 is provided with a honeycomb panel 5 across, and the top resin convex mirror 6 of the honeycomb panel 5 , the resin convex mirror 6 is provided with several exhaust holes 7, the top of the cooling box 1 and the top of the side away from the inlet 2 are provided with several air outlet por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com