Fabrication process of needle-free dosing joint

A production process and workbench technology, which is applied in the direction of drug devices, connecting tubes, other medical devices, etc., can solve the problems of inability to form reliable positioning, poor sealing, and poor structural stability between the rubber plug and the joint body, and improve the positioning effect. , the effect of reducing viscous force and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

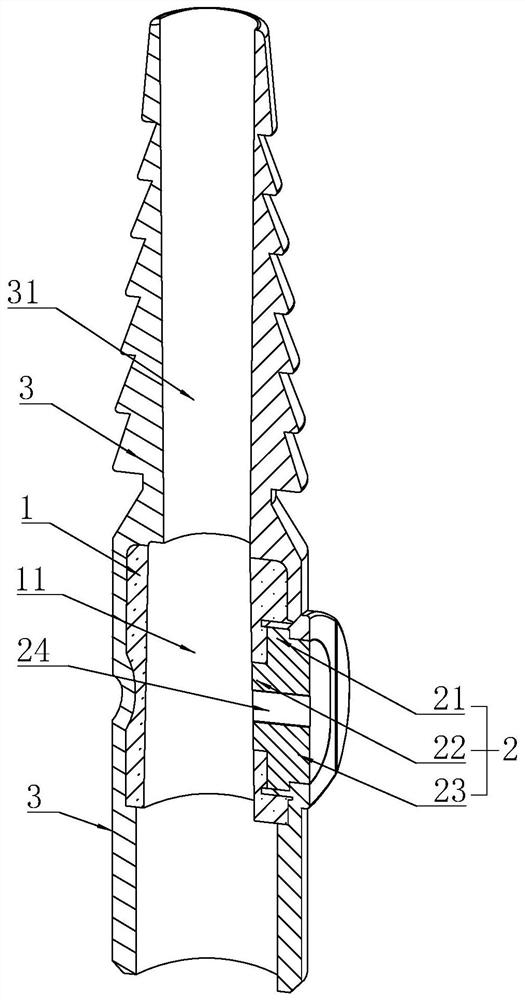

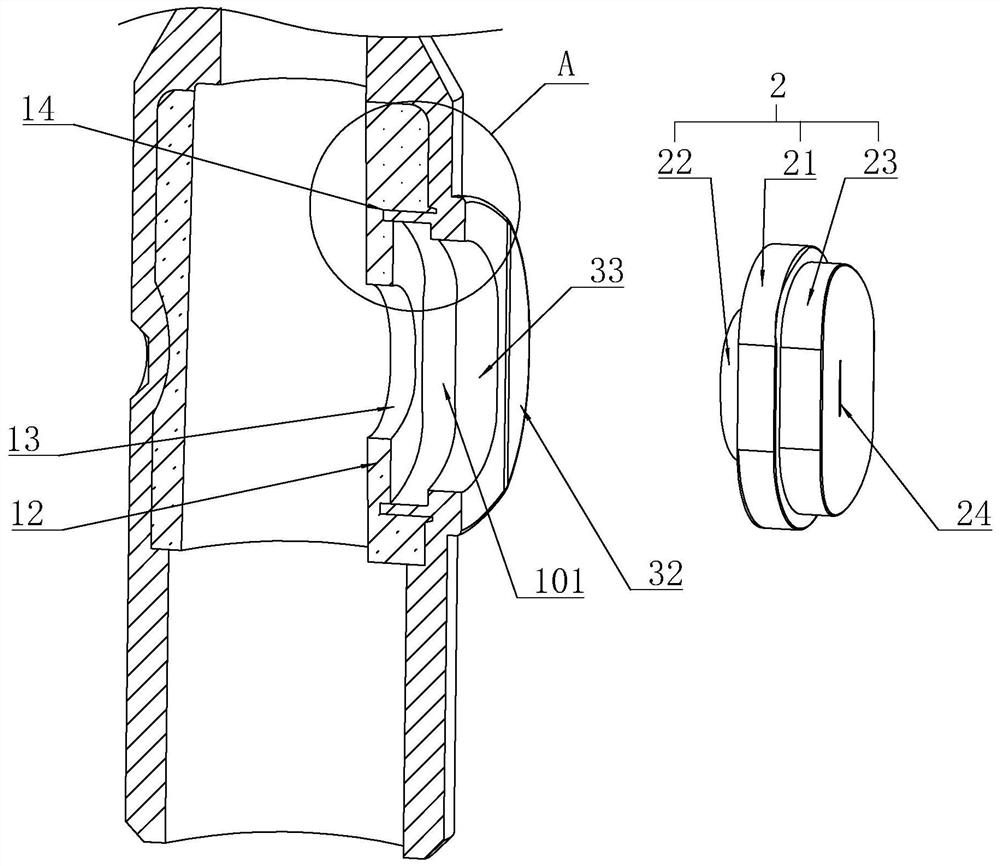

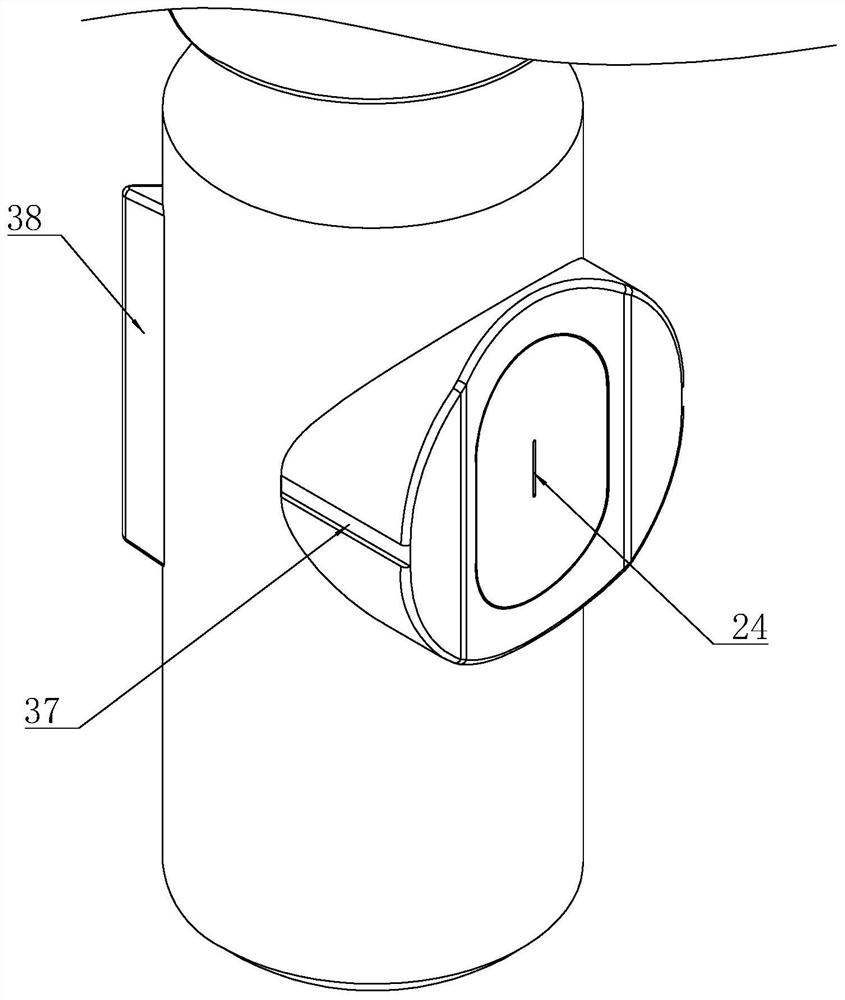

[0049] Embodiment 1: The manufacturing process of the needle-free medicated joint, such as figure 1 As shown, the medicated joint includes an inner sleeve 1 with a liquid hole 11, a shell 3 with a liquid hole 31, and a rubber plug 2. The liquid hole 31 communicates with the liquid hole 11 and is used as a normal infusion. The combination between the inner sleeve 1 and the outer shell 3 forms a sampling chamber 101 for the rubber plug 2 to engage and prevent the rubber plug 2 from escaping.

[0050] The rubber plug 2 is made of vulcanized silica gel. The rubber plug 2 includes a base 21, an inner convex portion 22 protruding toward the liquid hole 11 relative to the base 21, and an outer convex portion 23 facing outward relative to the base 21. The inner convex portion 22 is a cylinder. The outer convex part 23 and the base part 21 are elliptical cylinders, and the projection planes of the outer convex part 23 and the inner convex part 22 all fall in the projection plane of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com