Resin composition for printing film and printing film

A technology of resin composition and printing film, which is applied in the field of resin composition for printing film and printing film, can solve the problem that the stabilizer cannot obtain the stabilization effect, and achieve the effect of excellent printability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

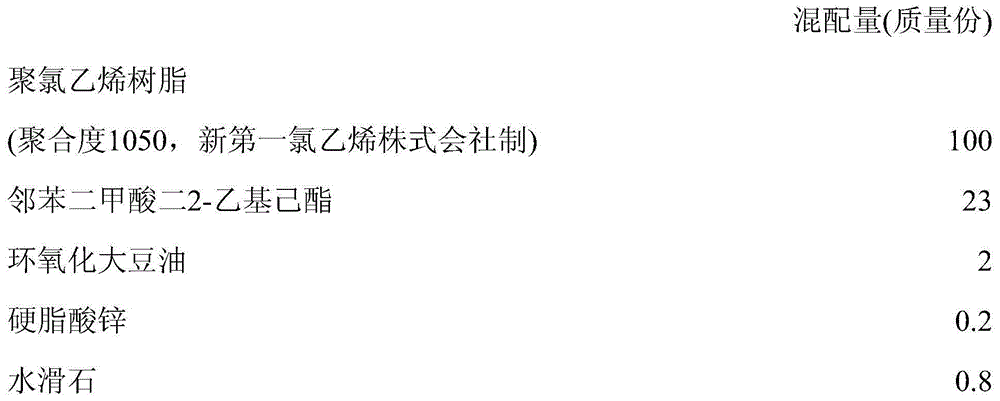

[0074] Hereinafter, although an Example is shown and the resin composition for printing films of this invention is demonstrated in more detail, this invention is not limited to this.

[0075]According to the following formulation example, the resin composition mixed with each component was kneaded on a roll at 180°C and 30 rpm for 5 minutes, and then pressed at 180°C for 5 minutes to produce a thickness of 1mm and 30×15cm. Tablets were tested for their yellowness. In addition, the yellowness of the tablet after pressing for 30 minutes was also measured under the same conditions. Moreover, the test piece of 5 x 15 cm was produced from this piece, it heated in the Geer oven (Geer oven) of 190 degreeC, and measured the time until blackening, and evaluated thermal stability.

[0076] Moreover, the resin composition which mixed each component was kneaded at 180 degreeC and 30 rpm according to the following formulation example, and the time until sticking was evaluated as grinding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com