Method for detecting a malfunction in a camshaft offset device

A technology of offset device and fault detection, applied in valve device, engine starting, electrical control and other directions, can solve the problem of inaccurate and reliable fault detection, and achieve the effect of reliable diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The method according to the invention is carried out automatically by means of a computer, for example the central processing unit of the motor vehicle. All steps of the method according to the invention are carried out systematically and automatically by this computer, without intervention of the driver of said vehicle.

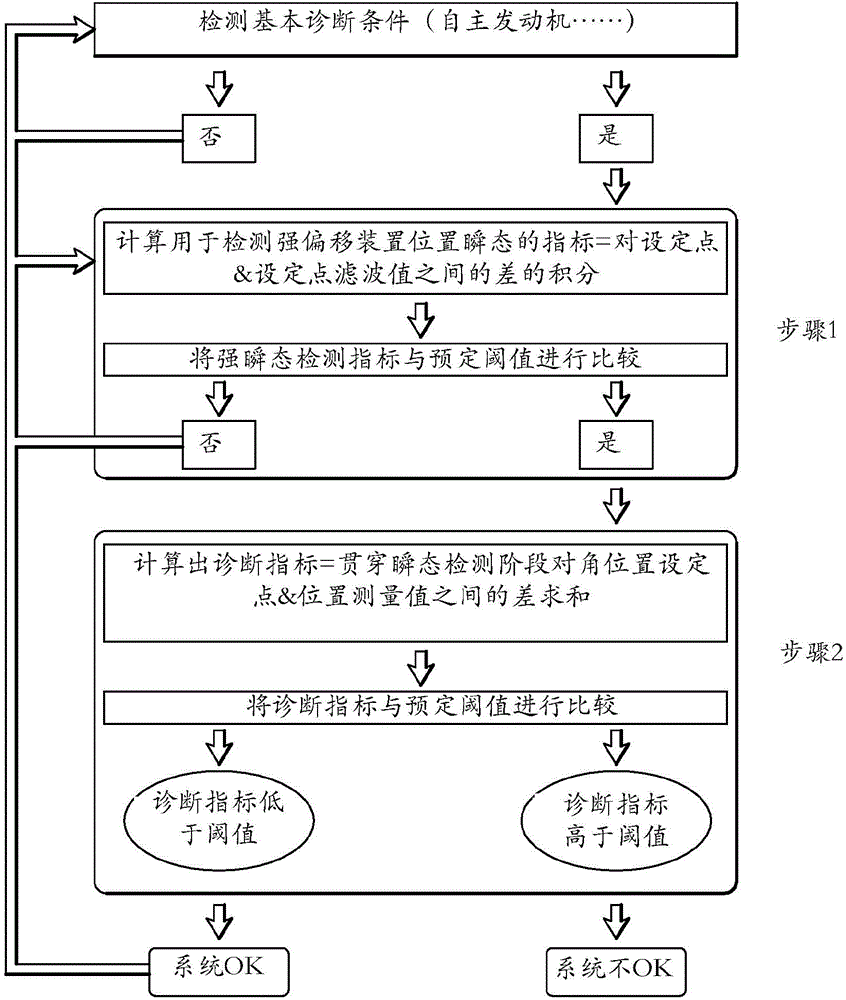

[0032] see figure 1 , the method according to the invention comprises an initial step consisting in verifying that the engine of the vehicle is under standard operating conditions. In fact, if the engine has to function in extreme environments, for example at very high temperatures, there may be a risk that the results provided by the method according to the invention will not be reliable, not least because of the thermal expansion of the deflection means, This would unnaturally impair its operation and / or its control.

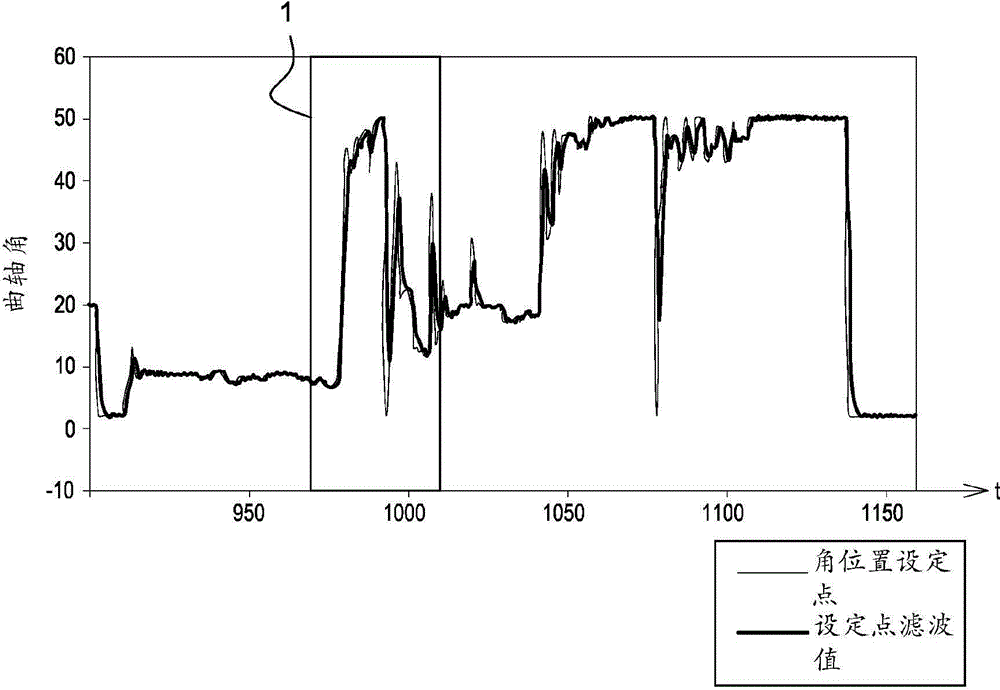

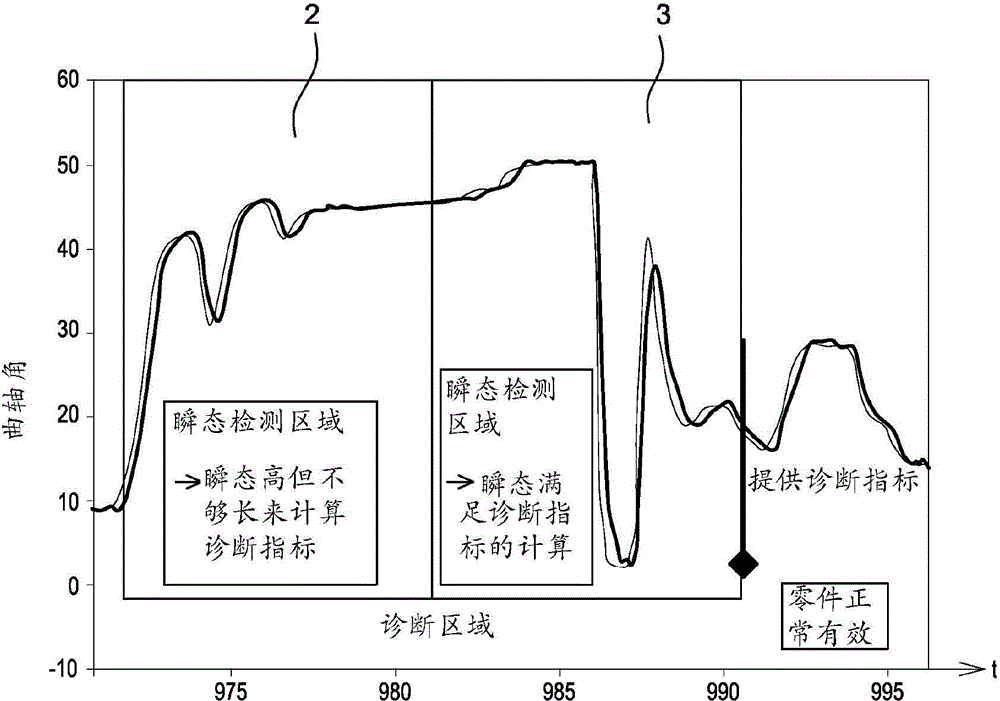

[0033] The method comprises a first step of identifying at least one potential diagnostic area which can be used as a basis for a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com