Differential pressure sensor and method for the production thereof

A sensor and differential pressure technology, applied in the field of differential pressure sensor and its manufacturing, can solve complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

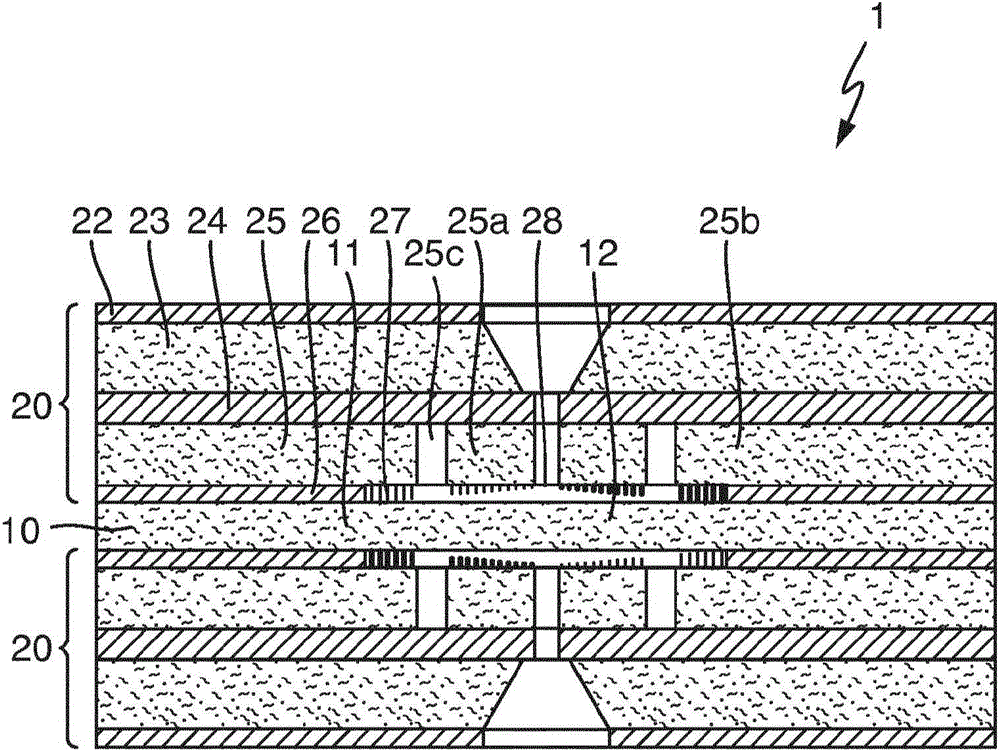

[0040] figure 1 The differential pressure sensor 1 shown in includes a silicon measuring membrane 10 which is arranged between two platforms 20 and is in pressure-tight connection with them along an annular edge region 11 which The deflectable area 12 surrounds the shape of a disc. The measuring membrane has a thickness of several tens of μm, for example about 40 μm, wherein the thickness of the measuring membrane is selected relative to the radius of the deflectable region as a function of the required measuring range. In this example of embodiment, the radius of the deflectable region 12 of the measuring membrane is eg 1100 μm.

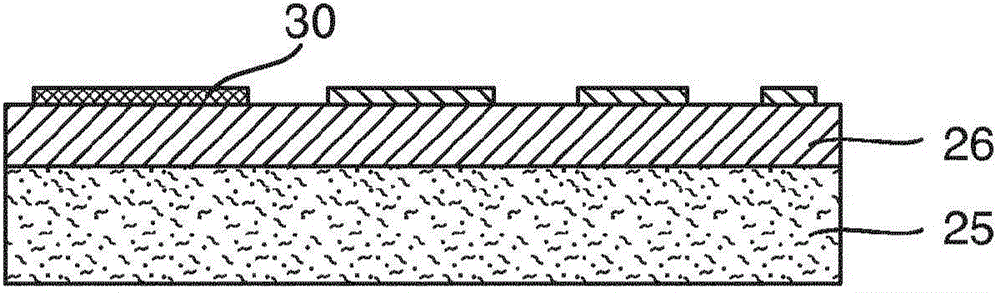

[0041] The two platforms 20 preferably have a micromechanically substantially symmetrical configuration with respect to the center plane of the measuring membrane, so that the following description of the structure of one platform 20 also applies to the other platform 20 . The platform 20 has a layered structure, the layer order of which will now be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com