Plug connector with sealing element

A technology for connecting devices and sealing elements, which is applied to the parts, connections, electrical components and other directions of connecting devices, can solve problems such as contact sleeve pollution and interference with electrical connections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

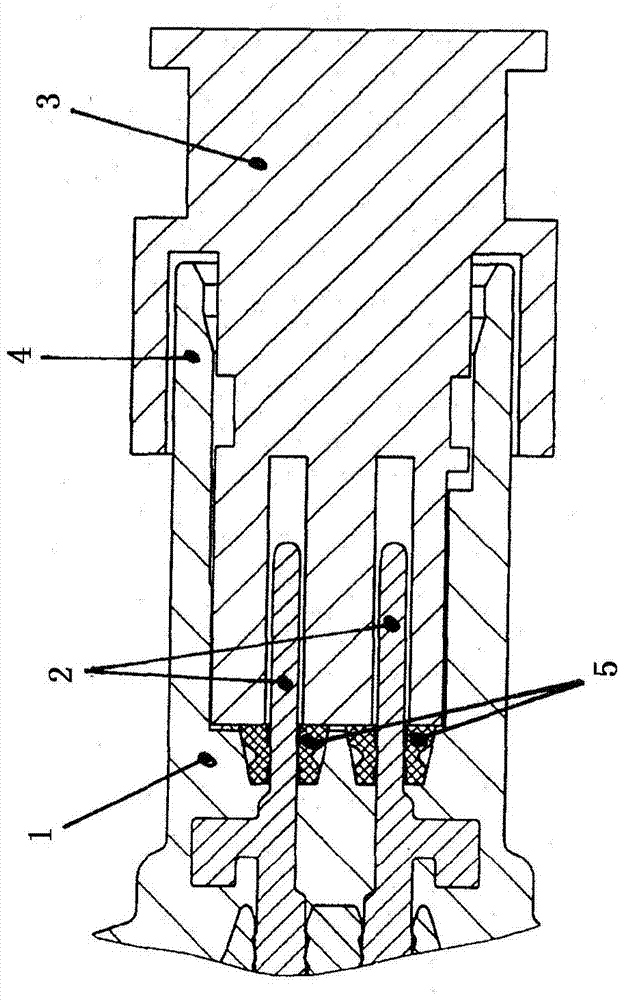

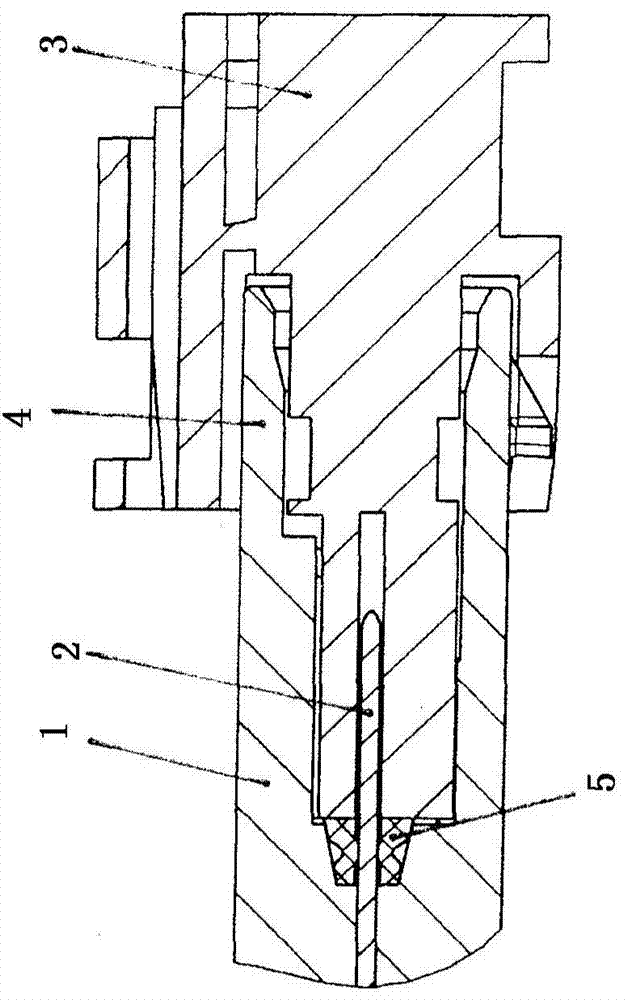

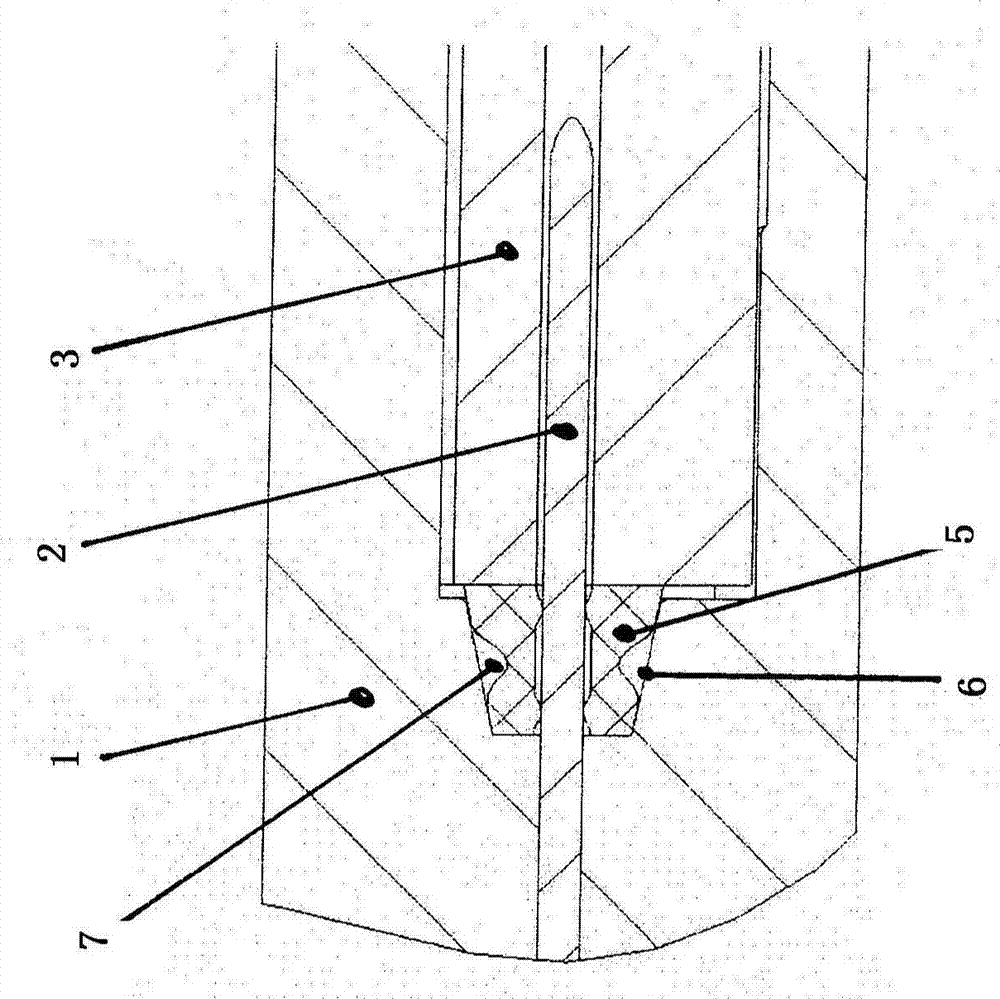

[0015] exist figure 1 with Image 6 A plug connector marked with 1 is shown in detail in , on which contact pins 2 are arranged, which protrude from the inner surface of the plug connector 1 . A mating socket, in which a sleeve contact (not shown) is arranged, is marked with 3 . The contact pin 3 and the not shown sleeve contact are electrically connected on the one hand to the electromagnet and on the other hand to the control line. The extension sleeve 4 of the connector is provided with buckling lugs, which correspond to the side recesses on the mating connector, so that the connector and the mating connector are engaged together and After tensioning are fixed and locked relative to each other. The sealing element 5 is pushed onto the contact pin 2 before the socket 1 and the mating socket 3 are joined together. Recesses 6 , which are conical or pyramid-shaped, are machined into the plug connector 1 . The sealing element 5 has a corresponding outer shape so that it fit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com